In any water electrolysis machine—whether it is a residential alkaline water ionizer or an industrial hydrogen generator—the metal electrode is the core component. The quality of the electrode directly dictates the quality of the treated water and the longevity of the machine.

During the electrolysis process, the environment inside the cell is incredibly harsh. The water generates strong oxidizing substances such as Ozone ($O_3$), Hydrogen Peroxide ($H_2O_2$), and Hypochlorous Acid ($HClO$). Furthermore, many modern systems frequently reverse polarity to clean the plates.

To withstand these conditions, standard metals often fail. This is why Titanium-based coated electrodes have emerged as the industry standard.

Why Titanium? 5 Essential Requirements for Electrodes

For an electrode to function effectively in water treatment and industrial electrolysis, it must meet five strict criteria. Our Titanium electrodes are engineered to exceed these requirements:

Superior Conductivity: To ensure efficient energy transfer.

Strong Corrosion Resistance: To withstand acidic, alkaline, and oxidative environments.

Mechanical Strength: Durable enough to resist processing and high-pressure flows.

Long Service Life: Reducing maintenance costs and downtime.

High Electrocatalytic Performance: Maximizing the reaction rate and efficiency.

The Technology: Platinum Group Coatings

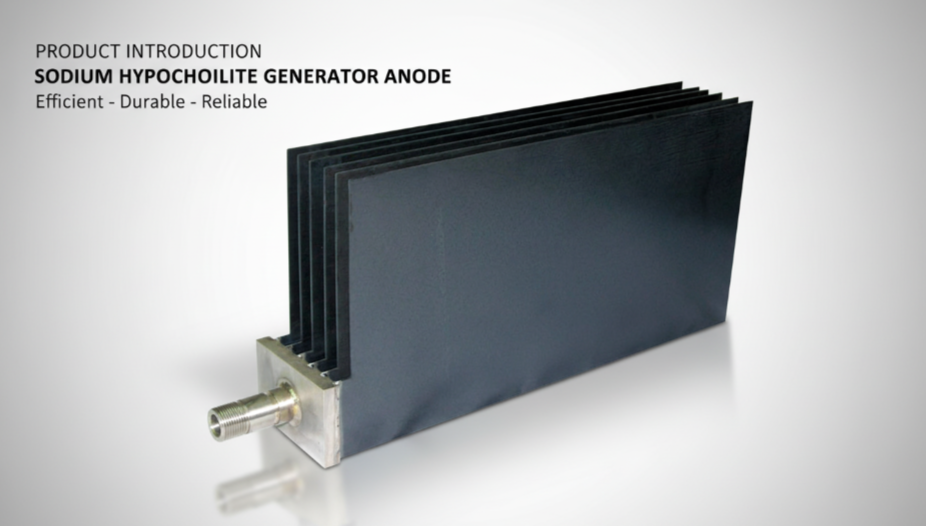

We have developed a specialized Titanium Metal Coated Electrode designed specifically for the water treatment sector. These are “Insoluble Anodes” created by coating a pure Titanium (TA1) substrate with high-performance Platinum group precious metal oxides.

Key Technical Advantages

Resistance to “Wet Chlorine”: In electrolysis, even trace amounts of chloride ions can cause rapid pitting corrosion in stainless steel plates. Titanium is immune to this, ensuring the electrode does not degrade or contaminate the water.

Energy Efficiency: The addition of Platinum group metals significantly lowers the overpotential, meaning higher current efficiency and better conductivity. This translates to energy savings during operation.

Polarity Reversal Capable: Our electrodes are designed to handle the frequent current reversals used in self-cleaning water machines without shedding their coating.

Lightweight & Strong: Titanium has a low specific gravity but high strength, reducing the overall weight of the equipment while maintaining structural integrity.

Product Specifications & Standards

Our manufacturing process allows for high customization to fit specific machinery, from hydrogen water cups to large-scale industrial tanks.

Base Material: Titanium Gr1 (TA1)

Coating: Platinum (Pt) / Precious Metal Oxide

Coating Thickness: 1-5 microns (Customizable based on lifespan requirements)

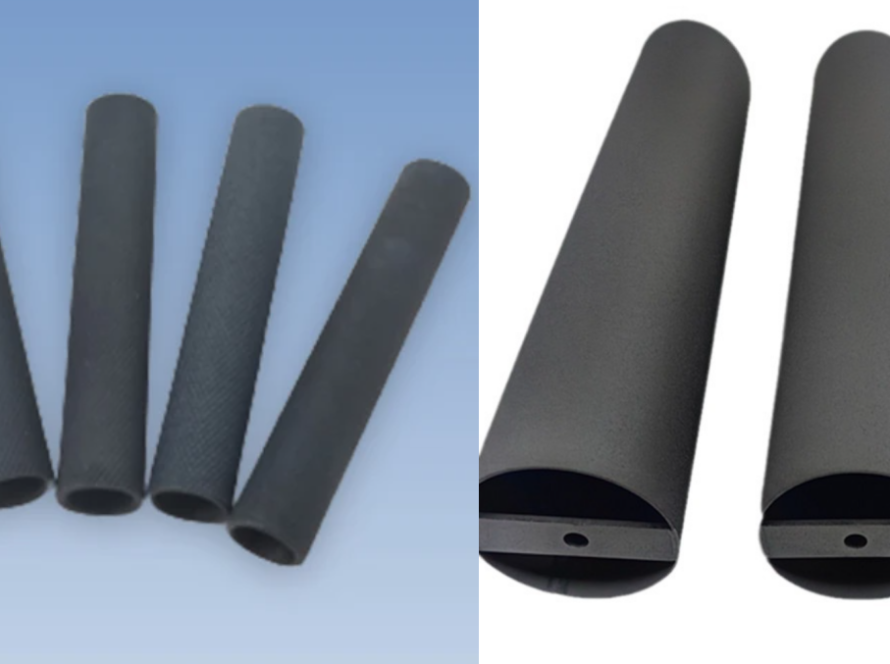

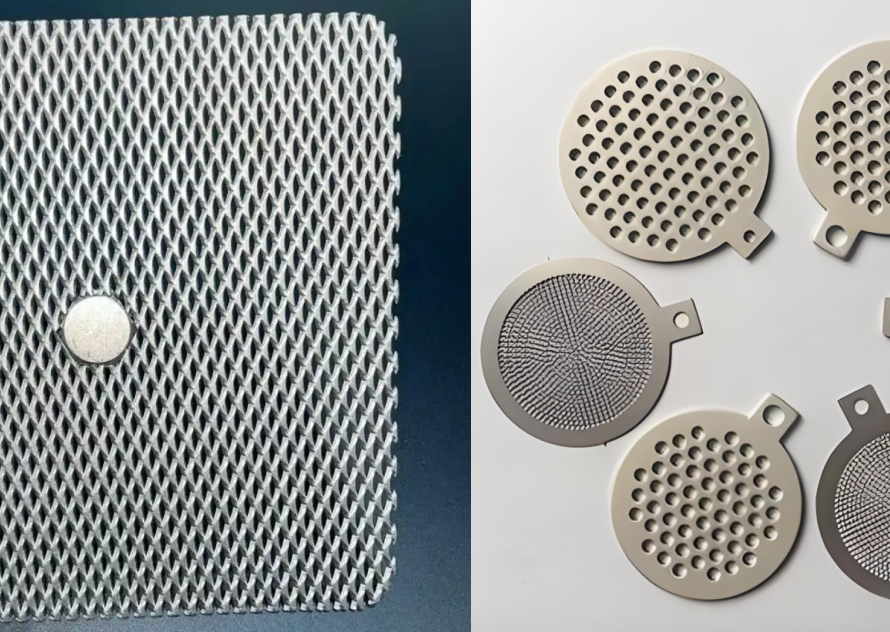

Available Shapes: Plate, Mesh, Tube, Rod, Wire, Ring, and custom irregular parts.

Features: High current density, low overpotential, no secondary pollution.

Applications

Our Titanium Anodes are versatile and used across multiple sectors:

1. Water Electrolysis & Consumer Appliances

Alkaline/Acid Water Machines: Beauty machines and water ionizers.

Hydrogen-Rich Water: Electrodes for the bottom of hydrogen water cups and jugs.

Disinfection: Household vegetable washing machines and swimming pool chlorinators.

2. Environmental Protection & Wastewater

Industrial Wastewater: Degradation of COD (Chemical Oxygen Demand).

Sewage Treatment: Treatment of household and oily/benzene-containing sewage.

3. Industrial Metallurgy & Plating

Electrowinning: Extraction of non-ferrous metals (Copper, Nickel, Cobalt, Zinc, Silver, Indium).

Auxiliary Anodes: For electroplating Gold, Rhodium, Nickel, and Chrome.

Copper Recovery: Used in etching solution recovery (direct recovery and extraction methods).

PCB Manufacturing: Titanium anode plates for Copper foil and PS plate production.

Whether you are manufacturing high-end medical beauty devices or managing heavy-duty industrial wastewater plants, the choice of electrode determines your success. Our Platinized Titanium Anodes offer the durability, conductivity, and catalytic power necessary to drive modern electrochemical processes efficiently.