When selecting titanium sheet metal for your next project, the choice often boils down to two heavyweights: Grade 5 (Ti-6Al-4V) and Grade 2 (Commercially Pure). While both share the legendary lightweight and corrosion-resistant properties of titanium, they serve vastly different engineering needs.

As a leading Grade 5 titanium sheet metal supplier, Ti Time Company understands that choosing the right grade is critical for performance, safety, and cost-efficiency. Whether you are engineering aerospace components or marine heat exchangers, this guide explores the nuances of these materials and how our custom manufacturing capabilities can meet your exact specifications.

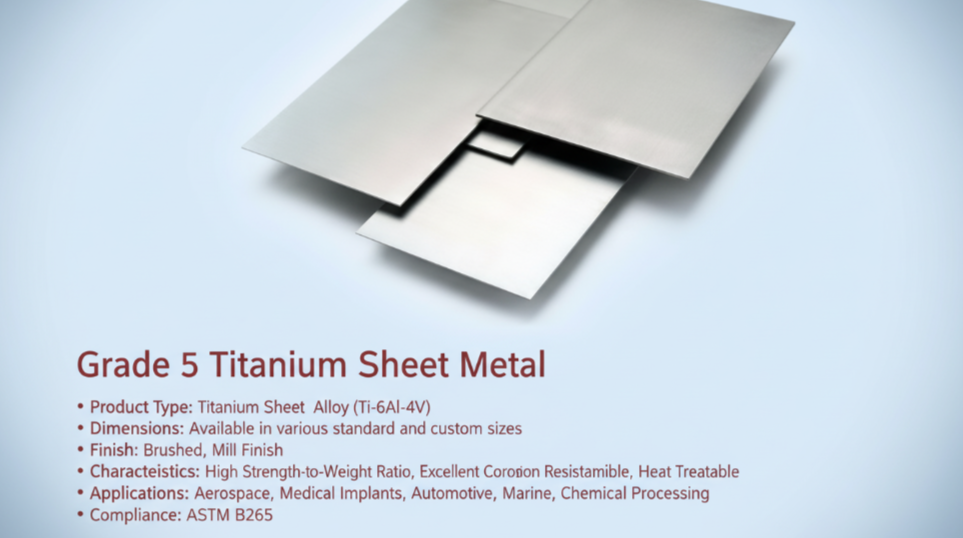

Grade 5 Titanium Sheet Metal: The Strength Leader

Grade 5 Titanium (Ti-6Al-4V) is the workhorse of the titanium industry, accounting for over 50% of total titanium usage worldwide. It is an alpha-beta alloy containing 6% Aluminum and 4% Vanadium.

Why Choose Grade 5?

Unrivaled Strength-to-Weight: Grade 5 is significantly stronger than Grade 2—roughly 2 to 3 times the tensile strength. This makes it the go-to material where every gram of weight savings counts, but failure is not an option.

Heat Resistance: It maintains its mechanical properties at higher temperatures (up to 400°C), making it ideal for engine components and exhaust systems.

Biocompatibility: Despite being an alloy, it is widely used in medical implants due to its non-toxic nature and ability to bond with bone.

Typical Applications: Aerospace airframes, high-performance automotive racing parts, turbine blades, and structural brackets.

Grade 2 Titanium Sheet Metal: The Corrosion Specialist

Grade 2 is “Commercially Pure” (CP) titanium. It lacks the alloying elements of Grade 5, which gives it a different set of superpowers.

Why Choose Grade 2?

Superior Formability: Unlike the stiffer Grade 5, Grade 2 possesses excellent ductility. It can be cold-formed, bent, and deeply drawn into complex shapes like tanks or heat exchanger plates without cracking.

Maximum Corrosion Resistance: In highly aggressive environments—such as saltwater, chlorides, or acidic chemical processing—Grade 2 offers slightly better corrosion resistance than its alloyed counterpart.

Cost-Effectiveness: Generally, CP titanium is less expensive to process and fabricate.

Typical Applications: Chemical processing equipment, desalination plants, marine hardware, and architectural cladding.

Ti Time Company: Your Custom Manufacturing Partner

At Ti Time Company, we are more than just a stockist; we are a dedicated Grade 5 titanium sheet metal supplier focused on precision and customization. We understand that off-the-shelf sizes don’t always fit sophisticated engineering designs.

Our Customization Capabilities

Precision Rolling & Cutting: We supply sheets in standard ASTM dimensions or cut-to-size based on your blueprints.

Surface Finishes: From matte pickling to polished surfaces for aesthetic applications.

Grade Selection Advice: Not sure if you need the ductility of Grade 2 or the brute strength of Grade 5? Our technical team provides expert consultation to ensure you pick the right alloy for your environment.

Frequently Asked Questions (FAQ)

1. Can Grade 5 titanium sheet be cold formed like Grade 2? Generally, no. Grade 5 has high spring-back and lower ductility. Simple bends are possible with a generous radius, but complex shapes usually require hot forming or annealing. If your part requires deep drawing, Grade 2 is the better choice.

2. Is Grade 5 titanium magnetic? No, both Grade 2 and Grade 5 titanium are non-magnetic. This property is crucial for electronic shielding and medical applications where magnetic interference must be avoided.

3. Which grade is better for marine environments? While both are excellent, Grade 2 is often preferred for marine piping and heat exchangers because of its superior resistance to crevice corrosion in hot seawater and its ease of fabrication into complex pipe shapes.

4. What standards does Ti Time Company follow? We manufacture our Grade 5 titanium sheet metal strictly according to international standards such as ASTM B265, AMS 4911 (Aerospace), and ISO specifications to ensure global compliance and quality assurance.

5. How does the cost compare between Grade 2 and Grade 5? Grade 5 is typically more expensive than Grade 2. This is due to the cost of the alloying elements (Vanadium) and the increased difficulty in processing and rolling the stronger alloy into sheet form.