I. What is a Titanium Sputtering Target?

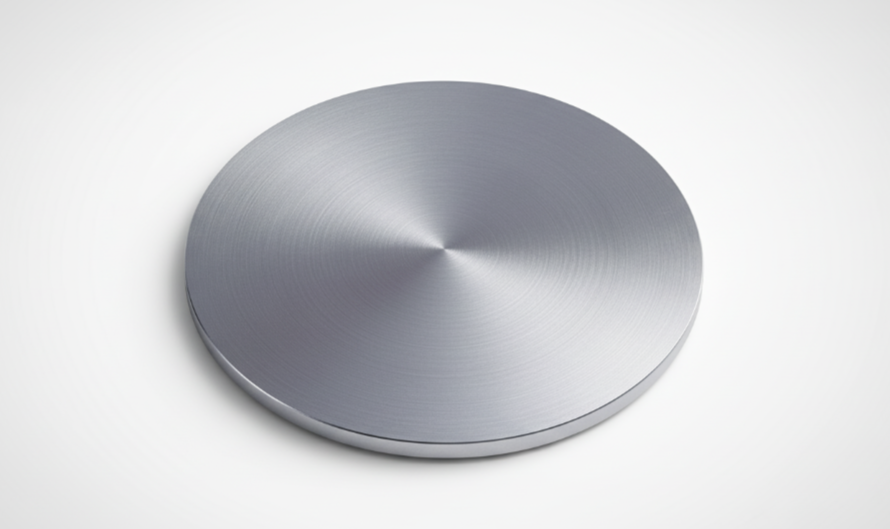

A titanium sputtering target is a high-purity material used in Physical Vapor Deposition (PVD) and Magnetron Sputtering processes. By bombarding the Ti target with high-energy ions, titanium atoms are ejected and deposited onto a substrate, creating thin films with exceptional hardness, corrosion resistance, and thermal conductivity.

At Ti Time Company, our targets feature:

Ultra-High Purity: Reducing impurities (Fe, Si, O, N, H) to below 100ppm to ensure electrical stability.

Superior Density: Achieving a density of over 99.5%, which prevents micro-cracking during high-power sputtering.

Refined Grain Structure: Uniform grain size ensures consistent deposition rates across the entire substrate surface.

II. Key Applications Across Industries

As a versatile titanium sputtering target supplier, Ti Time Company supports diverse technological applications:

Semiconductors & Electronics: Creating conductive interconnects and diffusion barriers in microchips and LCD screens.

Optical Coatings: Manufacturing anti-reflective (AR) and high-reflectivity coatings for eyeglasses and camera lenses.

Aerospace & Automotive: Deposition of wear-resistant and anti-corrosive layers on engine components and piston rings.

Medical Implants: Enhancing the biocompatibility of orthopedic and dental implants through bioactive coatings.

Energy Solutions: Manufacturing electrode layers for solar cells and protective films for photovoltaic devices.

III. Advanced Manufacturing Methods at Ti Time

Ti Time Company utilizes state-of-the-art production techniques to meet the rigorous demands of global OEMs:

Vacuum Melting & Forging: We use multi-stage vacuum arc remelting (VAR) followed by precise forging to ensure a dense, defect-free internal structure.

Powder Metallurgy (Sintering): Ideal for custom alloy targets, providing high material utilization and cost-efficiency.

3D Printing & Additive Manufacturing: Tailored for complex, non-standard target geometries and specialized R&D applications.

Ion Injection & ALD Preparation: Specialized methods for functionalized composite targets and atomic-layer-thin diffusion barriers.

IV. Why Choose Ti Time Company as Your Supplier?

Selecting the right titanium sputtering target supplier is critical for maintaining production uptime and film quality. Ti Time Company stands out through:

Custom Manufacturing: We specialize in the custom production of all titanium sputtering target products. Whether you need planar targets, rotary targets, or custom dimensions, we manufacture to your exact specifications.

Deep Technical Expertise: Our engineering team possesses decades of experience in metallurgy and PVD processes.

Rigorous Quality Control: Every target undergoes ultrasonic non-destructive testing (NDT) and ICP-OES purity analysis.

Global Logistics & Support: We provide comprehensive technical consultation and after-sales support to ensure seamless integration into your vacuum systems.

V. FAQ: Understanding Titanium Sputtering Targets

Q: How does target purity affect thin-film performance? A: Higher purity (e.g., 4N or 4N5) reduces the risk of particle formation and “arcing” during sputtering, which is vital for the yield rates of semiconductor devices.

Q: Can Ti Time Company produce custom-shaped targets? A: Yes. We offer customized manufacturing for circular targets, rectangular (planar) targets, and rotatable (cylindrical) targets tailored to your specific vacuum chamber hardware.

Q: What is the benefit of a smaller grain size in a target? A: Smaller, uniform grains lead to a more uniform sputter rate and a smoother film surface, extending the overall service life of the target.

VI. Future Outlook and Market Trends

The demand for high-performance titanium targets is surging. While the semiconductor industry remains a primary consumer, the New Energy Vehicle (NEV) sector is expected to see the fastest growth through 2026. Ti Time Company is currently investing in next-generation high-purity refining technologies to meet the needs of the emerging quantum computing and hydrogen fuel cell markets.