What Is the Melting Point of Titanium Sheet Metal?

The melting point of titanium sheet metal is approximately 1,668°C (3,034°F). This exceptionally high melting point makes titanium one of the most heat-resistant structural metals used in modern industry.

It is important to note that the melting point remains essentially the same regardless of the product form—whether titanium is processed into sheets, plates, rods, or tubes. However, alloying elements (such as aluminum or vanadium in Ti-6Al-4V) may slightly influence thermal behavior and performance under extreme conditions.

Thanks to this high melting point, titanium sheet metal maintains excellent mechanical stability in high-temperature environments where stainless steel or aluminum would fail.

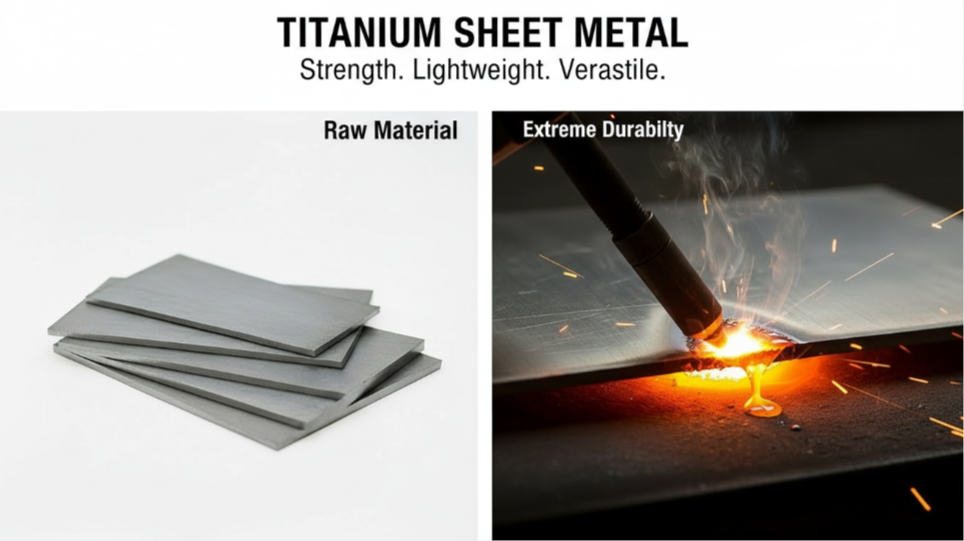

Titanium Sheet Metal: Key Characteristics and Advantages

Titanium sheet metal is widely used across aerospace, medical, chemical, and industrial sectors due to its outstanding balance of strength, weight, and corrosion resistance.

Key advantages include:

High strength-to-weight ratio – nearly as strong as steel but about 40% lighter

Excellent corrosion resistance – performs well in seawater, acids, and harsh chemical environments

Biocompatibility – ideal for medical implants and surgical instruments

Thermal stability – performs reliably under high temperatures due to its high melting point

Non-magnetic and low thermal expansion

Common grades of titanium sheet metal include Grade 1, Grade 2, Grade 5 (Ti-6Al-4V), each tailored for specific applications ranging from deep drawing to high-stress structural use.

Applications of Titanium Sheet Metal

Because of its unique properties, titanium sheet metal is used in a wide range of demanding applications:

Aerospace: aircraft skins, engine components, heat shields

Medical: surgical tools, implant components

Chemical processing: heat exchangers, reactors, pressure vessels

Marine engineering: seawater systems, offshore equipment

Industrial manufacturing: precision parts, protective linings

The high melting point of titanium sheet metal ensures long service life even in extreme thermal and chemical environments.

Titanium Sheet Metal for Sale: What to Look For

If you are searching for titanium sheet metal for sale, choosing the right supplier is just as important as selecting the right grade.

Key factors to consider:

Compliance with international standards (ASTM, AMS, ASME, etc.)

Consistent thickness tolerance and surface quality

Availability of custom sizes and grades

Reliable supply chain and export experience

Proven quality management systems (ISO certified)

A trusted supplier will not only provide competitive pricing, but also technical support, documentation, and stable long-term supply.

Why Titanium Sheet Metal Is a Smart Investment

Although titanium sheet metal typically costs more than stainless steel or aluminum, its long-term performance, durability, and low maintenance requirements often make it the most cost-effective choice over a product’s lifecycle—especially in critical or high-risk environments.

For manufacturers focused on performance, safety, and reliability, titanium remains a premium but highly justified material solution.

Your Trusted Partner for High-Quality Titanium and Advanced Materials

Your Trusted Partner for High-Quality Titanium and Advanced Materials.

Ti Time is a leading manufacturer and supplier specializing in titanium, tungsten, molybdenum, tantalum, niobium, zirconium, anodes, and composite materials. With decades of experience, we are known for delivering high-quality products and exceptional customer service. Our offerings include plates, rods, tubes, foils, wires, screws, capillary tubes, targets, custom parts, forgings, and alloys. Operating under the ISO9001 quality system, our products meet ASTM, ASME, AMS, JIS, DIN, and MIL standards, and are exported to countries such as the US, Japan, Germany, and South Korea.