Description

Precision Engineering: Powdered TiAl Target for Hard Coatings, 99.8% Purity

I. The Science of the Powdered TiAl Target for Hard Coatings, 99.8% Purity

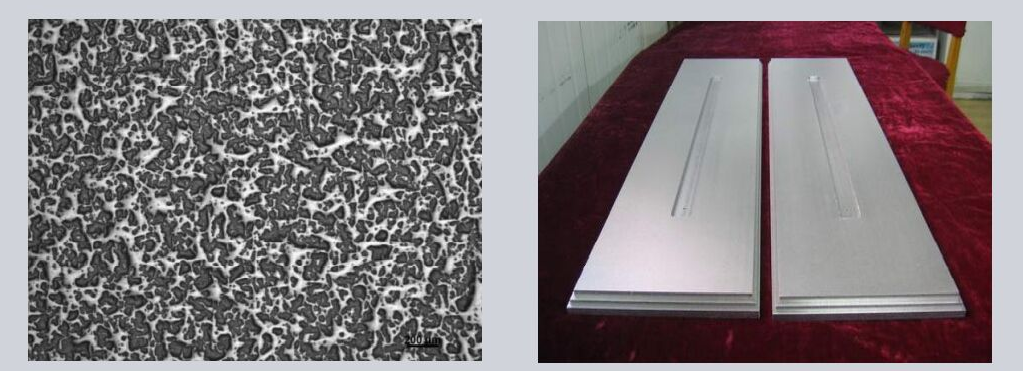

A Powdered TiAl target for hard coatings, 99.8% purity is produced using advanced powder metallurgy techniques such as Hot Isostatic Pressing (HIP) or Vacuum Hot Pressing. This process is essential for intermetallic alloys like Titanium-Aluminum, which are too brittle for traditional casting but require extreme uniformity.

Purity & Performance: At 99.8% purity (2N8), our targets minimize metallic impurities like Iron (Fe) and Silicon (Si) to below 2,000 ppm. This ensures the resulting film is free from pinholes and maintains stable electrical properties during reactive sputtering.

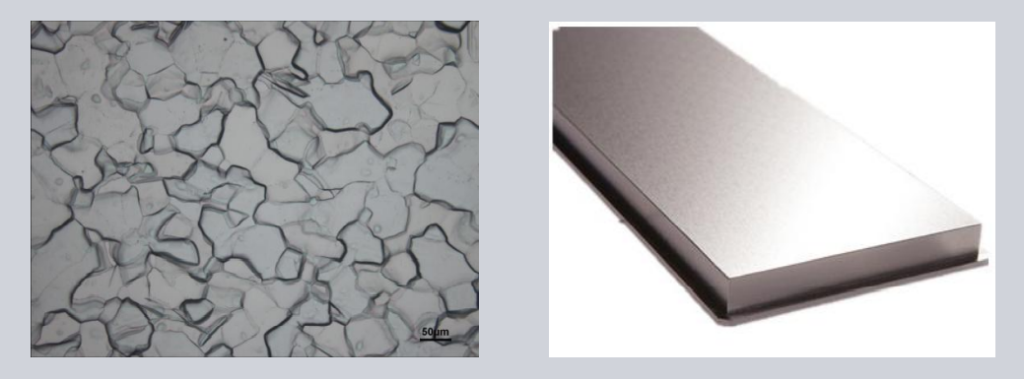

Stoichiometric Precision: Whether your process requires a Ti:Al 50:50 at.% or a specialized 48:52 at.% ratio, Ti Time Company ensures a homogeneous phase distribution, typically centered around the $\gamma-TiAl$ intermetallic phase.

High Density: We achieve relative densities of $\geq 99\%$, which is critical for preventing “spitting” or arcing in DC magnetron sputtering systems.

II. Why Ti Time is Your Preferred Powdered TiAl Target for Hard Coatings, 99.8% Purity Supplier

Choosing Ti Time Company as your supplier means partnering with a manufacturer that understands the nuances of thin-film physics.

Custom Geometry: We offer customized production for planar (rectangular and circular) and rotary/tubular targets. Our rotary TiAl targets are particularly valued in large-scale architectural glass and web coating lines.

Optimized Grain Structure: Our powder consolidation process produces a fine, equiaxed grain structure. This leads to a more uniform erosion rate, extending target utilization and providing consistent film thickness across the substrate.

Comprehensive Testing: Operating under the ISO9001 quality system, every target undergoes Ultrasonic NDT (Non-Destructive Testing) for internal voids and ICP-OES analysis for chemical verification.

III. Applications in High-Stress Environments

The Powdered TiAl target for hard coatings, 99.8% purity is primarily used in reactive sputtering (Ar + $N_2$) to form Titanium Aluminum Nitride (TiAlN). This coating is indispensable for:

High-Speed Cutting Tools: Increasing the oxidation resistance and “red hardness” of CNC drills and inserts.

Aerospace Components: Providing thermal barriers and wear-resistant layers for turbine blades.

Automotive Parts: Reducing friction in engine components and enhancing the durability of decorative trim.

IV. FAQ: Expert Insights on TiAl Sputtering Targets

Q1: Why is a powdered target better than a cast target for TiAl?

A: Titanium and Aluminum have significantly different melting points and densities, making casting prone to segregation (uneven mixing). Powder metallurgy ensures a perfectly homogeneous atomic distribution, which is vital for a stable sputtering process.

Q2: What is the benefit of 99.8% purity for industrial tool coatings?

A: While semiconductor grades require 99.999% purity, 99.8% purity is the “sweet spot” for hard coatings. It provides the mechanical toughness required for tools while keeping the titanium sputtering target price competitive for high-volume manufacturing.

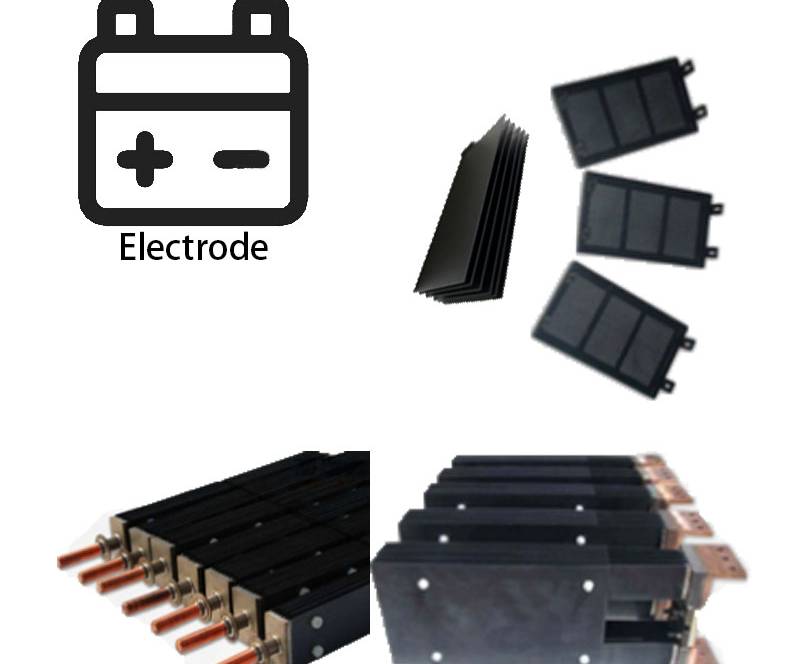

Q3: Can these targets be bonded to copper backing plates?

A: Yes. We recommend Indium or Elastomer bonding to a copper backing plate for planar targets to ensure efficient heat dissipation. This allows for higher power densities (up to 50 W/$cm^2$) without cracking the brittle TiAl material.

Q4: How does the Ti:Al ratio affect the final coating?

A: Higher Aluminum content generally improves the oxidation resistance and hardness of the TiAlN film. However, if the Al content is too high, the crystal structure can shift, potentially reducing the film’s toughness. Our experts can help you select the ideal ratio for your specific application.

Q5: What are the storage requirements for TiAl targets?

A: Targets should be stored in a dry, vacuum-sealed environment. Because Aluminum can oxidize and the intermetallic phase is sensitive to humidity, keeping the targets in their original Ti Time Company packaging until use is highly recommended.

V. Ti Time Company: Global Excellence in Advanced Materials

Ti Time Company is a leading manufacturer and supplier specializing in titanium, tungsten, molybdenum, and composite materials. With decades of experience, we are known for delivering high-quality products and exceptional customer service.

Our offerings include plates, rods, tubes, targets, and custom forgings. Our products meet ASTM, ASME, AMS, and MIL standards, and we proudly export to the US, Japan, Germany, and South Korea. Whether you need a platinum coated titanium electrode or a Powdered TiAl target for hard coatings, 99.8% purity, we are your partner in precision.

Reviews

There are no reviews yet.