Titanium Alloy 6Al 4V: The Ultimate Standard for Aerospace and Medical Engineering

In the realm of high-performance metallurgy, titanium alloy 6al 4v (commonly known as Grade 5) is the undisputed champion, accounting for over 50% of total titanium usage worldwide. Renowned for its exceptional strength-to-weight ratio, this alpha-beta alloy is the material of choice for critical applications where failure is not an option.

At Ti Time Company, we specialize in the customized manufacturing of this versatile material. Whether your project requires raw ASTM-certified bars for aerospace machining or finished, anodized titanium components for corrosion resistance, our ISO9001-certified facilities deliver precision and reliability to the US, German, and Asian markets.

II. The Superior Properties of Titanium Alloy 6Al 4V

Titanium alloy 6al 4v derives its name from its chemical composition: roughly 6% Aluminum and 4% Vanadium. This specific blend creates a two-phase (alpha + beta) microstructure, which offers a unique balance of properties that pure titanium cannot match.

High Specific Strength: With a density of ~4.43 g/cm³, it is roughly 60% the weight of steel yet offers comparable tensile strength (approx. 895–940 MPa).

Heat Treatability: Unlike commercially pure grades, Grade 5 can be heat-treated to achieve even higher strengths for structural applications.

Corrosion Resistance: It maintains excellent resistance to oxidizing environments, chlorides, and seawater, making it ideal for marine and chemical industries.

III. Applications: Where Ti-6Al-4V Excels

As a premier supplier, Ti Time Company provides materials that power the world’s most demanding sectors. The versatility of titanium alloy 6al 4v makes it indispensable in:

Aerospace & Defense: Used in turbine blades, structural airframes, and fasteners where high fatigue strength and low weight are critical for fuel efficiency.

Medical Technology: We supply the Ti-6Al-4V ELI (Extra Low Interstitial) variant. This higher-purity version has improved ductility and fracture toughness, making it the gold standard for surgical implants and medical devices.

Automotive & Motorsport: From connecting rods to valve springs, this alloy reduces reciprocating mass in high-performance engines.

IV. Why Choose Ti Time for Your Titanium Alloy 6Al 4V Needs?

Sourcing titanium alloy 6al 4v involves more than just finding a stockist; it requires a partner who understands metallurgy. Ti Time Company distinguishes itself through:

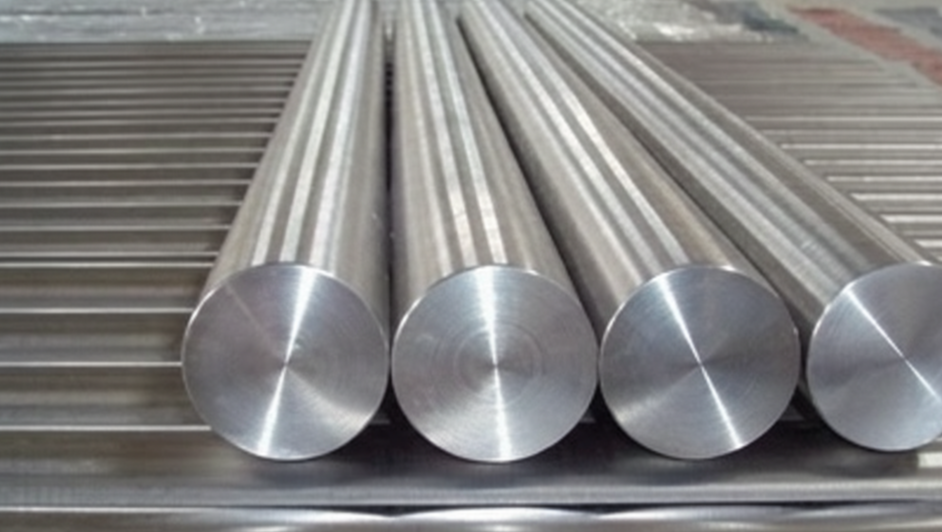

Customized Production: We don’t just sell standard stock. We forge, roll, and machine to your exact dimensions—plates, rods, wires, or custom profiles—reducing your machining time and material waste.

Surface Treatment: We offer value-added services, including anodized titanium finishes. Anodizing not only allows for color-coding (vital in medical kits) but also improves surface hardness and wear resistance.

Global Certification: Every shipment is accompanied by detailed Material Test Reports (MTRs) confirming compliance with AMS 4928 (Aerospace), ASTM F136 (Medical), or ASTM B348 (Industrial).

V. FAQ: Expert Insights on Titanium Alloy 6Al 4V

Q1: What is the difference between Grade 5 and Grade 23 (ELI)? A: Titanium alloy 6al 4v (Grade 5) is the standard industrial and aerospace grade. Grade 23 (Ti-6Al-4V ELI) is the “Extra Low Interstitial” version. It has tighter limits on oxygen and iron, which improves ductility and fracture toughness, making it essential for medical implants and cryogenic applications.

Q2: Is Titanium Alloy 6Al 4V hard to machine? A: It is more challenging than steel due to its low thermal conductivity (heat concentrates at the tool edge). However, with the right tooling speeds, feeds, and coolant, it can be machined precisely. Ti Time Company can also supply “near-net-shape” forgings to minimize the machining required.

Q3: Can Ti Time Company supply anodized Ti-6Al-4V parts? A: Yes. We provide anodized titanium in various colors (Type III) for identification or aesthetics, and Type II grey anodizing for anti-galling and wear resistance, which is crucial for threaded fasteners.

Q4: What forms of Ti-6Al-4V do you export? A: We export a full range of mill products including billet, bar (round/flat/hex), plate, sheet, wire, and tube. We also offer custom forged rings and discs for industrial use.

Q5: How does the price of Grade 5 compare to Grade 2? A: Titanium alloy 6al 4v is generally more expensive than commercially pure Grade 2 due to the cost of the alloying elements (Vanadium) and the more complex melting and processing steps required to ensure homogeneity.

VI. Ti Time Company: Your Trusted Partner for Advanced Materials

Ti Time Company is a leading manufacturer and supplier specializing in titanium, tungsten, molybdenum, tantalum, niobium, zirconium, anodes, and composite materials. With decades of experience, we are known for delivering high-quality products and exceptional customer service.

Our offerings include plates, rods, tubes, foils, wires, screws, capillary tubes, targets, custom parts, forgings, and alloys. Operating under the ISO9001 quality system, our products meet ASTM, ASME, AMS, JIS, DIN, and MIL standards, and are exported to countries such as the US, Japan, Germany, and South Korea.