Description

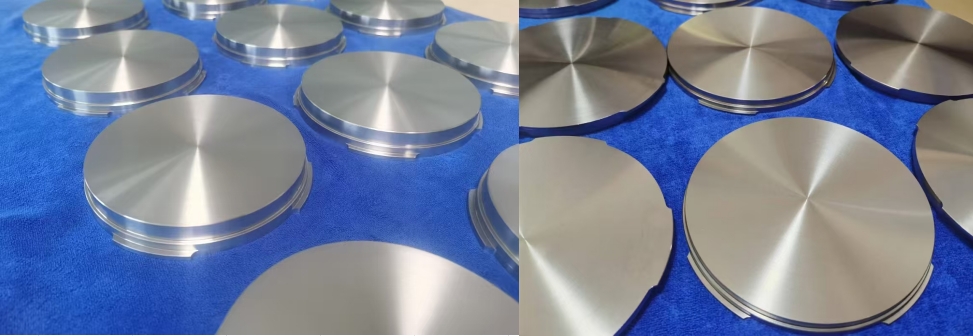

Chromium Sputtering Targets

Due to its excellent corrosion resistance and wear resistance, hard material-coated chromium (Cr) is widely used in combustion equipment and high-temperature fuel cells. In addition, our chromium is also used in electrical appliances and jewelry, as it provides an attractive shine when used as a decorative coating.

The purity of the chromium targets we supply is guaranteed because we manufacture our chromium targets in-house, from chromium powder to the finished product. Moreover, our targets have a uniform microstructure.

We offer flat and rotating chromium sputtering targets using Hot Isostatic Pressing (HIP) and Hot Pressing (HP) technologies.

We provide chromium targets with purities ranging from 99.5% to 99.95%. Additionally, we also accept custom chromium targets.

High Density

Uniform and Fine Microstructure

Even Distribution of Chemical Elements

Low Residual Impurity Content

Advantages:

- Smooth surface with no pores, scratches, or other defects

- Ground or turned edges without cutting marks

- Unmatched material purity

- Good ductility

- Homogeneous microstructure

- Laser marking available for your special items, including name, brand, purity, size, etc.

- Each sputtering target is made by us, from the type and quantity of powder materials, mixing workers, degassing, and HIP (Hot Isostatic Pressing) time, to machining personnel and packaging details.

All these steps ensure that once a new sputtering target or method is created, it can be replicated and preserved to support stable product quality.

Other Advantages:

High-Quality Materials such as Heat-Treated Chromium Targets

- 100% density = 7.19 g/cm³

- Size stability

- Enhanced mechanical properties

- Uniform grain size distribution

- Small grain size

Popular Uses:

- Cutting tool coatings, such as for cutting tools, drawing tools, molds and dies for various materials, bearings, shafts, gauges, gears, etc.

- Protection and decoration of components for automobiles, bicycles, sewing machines, clocks, instruments, daily hardware, and more.

- Storing lubricating media to prevent dry operation and improve wear resistance on the workpiece surface. Commonly used for coating sliding friction parts under heavy pressure, such as internal combustion engine cylinder bores, piston rings, etc.

- Uniform gloss, good decoration, and excellent anti-glare properties:

Protection and decoration of components for aerospace instruments, optical instruments, solar energy absorption panels, and everyday items.

Chromium-Aluminum

Due to its toughness, high thermal stability, and oxidation resistance, our chromium-aluminum (CrAl) targets are widely used as coatings for milling machines, drill bits, and other tools. Chromium-aluminum coatings can significantly improve metal removal rates, feed speeds, and cutting performance, while also extending tool lifespan.

We offer flat, rotating chromium-aluminum targets, as well as custom chromium-aluminum targets.

Important Details of Chromium-Aluminum

When you use our chromium-aluminum targets, our HIP technology ensures that the formation of droplets on your products during the coating process is significantly reduced. As a result, our chromium-aluminum targets provide smoother coatings.

Popular Uses:

- Coatings for cutting tools, such as cutting tools, drawing tools, molds and dies for various materials, bearings, shafts, gauges, gears, etc.

- Protection and decoration of components for automobiles, bicycles, sewing machines, clocks, instruments, daily hardware, and more.

- Storing lubricating media to prevent dry operation and improve wear resistance on the workpiece surface. Commonly used for coating sliding friction parts under heavy pressure, such as internal combustion engine cylinder bores, piston rings, etc.

- Uniform gloss, good decoration, and excellent anti-glare properties:

Protection and decoration of components for aerospace instruments, optical instruments, solar energy absorption panels, and everyday items.

Reviews

There are no reviews yet.