Description

Copper Supplier

Properties and Appearance of Copper

Copper is an element with the symbol Cu. It is a red, soft, malleable, and highly ductile metal. It is one of the best electrical conductors among common metals and is also a good thermal conductor, effectively transferring heat. Copper can easily be formed into various shapes through rolling, drawing, and hammering. It has antibacterial properties, capable of killing bacteria and viruses on its surface.

Ultra-Pure Copper Products

Suitable for the most demanding applications that require the highest purity copper.

It all starts with high-purity copper

Even small impurities can have a significant negative impact on the intended results, which is why we never compromise on the purity of raw materials. Our finished and semi-finished products are made from the highest purity copper.

We use only the highest-quality cathodes to produce our proprietary oxygen-free copper. This vertical integration allows us to fully control the quality and supply of both raw materials and products.

Oxygen-Free Copper and Copper Alloys Used:

- 99.9995% (5N5)

- OFE-OK® (4N5) 99.995% (5N)

- 99.995% (4N5)

- Other oxygen-free copper and copper alloys, such as CuP

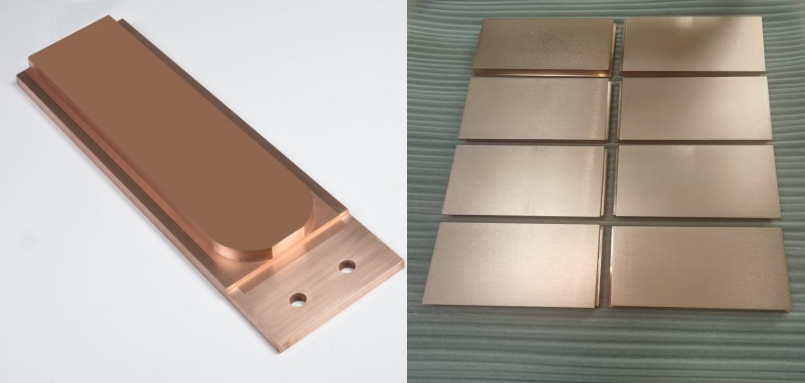

Copper Target (Cu)

Copper targets are used for film deposition via vacuum sputtering, widely applied in industries such as touch screens, semiconductors, sensors, circuit devices, and decorative items.

Parameters:

- Element Symbol: Cu

- Purity: 4N+

- Shape: Flat Target; Rotating Target

- Appearance: Red copper-colored metal

- Typical Density: 8.57 g/cm³

- Standard Dimensions:

- Flat Target: Ø500 mm

- Rotating Target: Length 4000 mm

- Custom Sizes Available

Copper Granules

TiTime specializes in the refining and manufacturing of high-purity copper granules for Physical Vapor Deposition (PVD) and Electrochemical Deposition (ECD).

This product can be customized according to customer requirements, ranging from very small particles to larger spheres or blocks. The purity range is from 4N5 to 6N (99.995% – 99.9999%). Special alloys such as CuP and CuIn are also available.

- Element Symbol: Cu

- Purity: 99.99% ~ 99.999%

- Shape: Blocks, Small Cylinders, Discs

- Appearance: Copper red with a metallic luster

- Melting Point: 1083.4°C

- Theoretical Density: 8.96 g/cm³

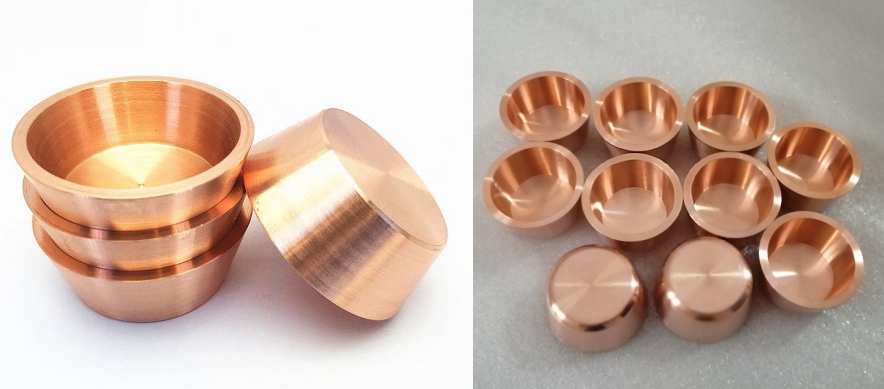

Copper Crucibles

Introduction:

A copper crucible is a container primarily made of copper or copper alloys, designed for high-temperature applications. Copper crucibles are renowned for their excellent thermal conductivity, which promotes efficient heat transfer, making them an ideal choice for processes that require rapid heating and cooling. Their corrosion resistance and high-temperature capabilities make them valuable in various industrial and laboratory environments.

Applications:

Metallurgical Processes:

Melting and Casting: Due to their efficient heat transfer properties, copper crucibles are widely used for melting non-ferrous metals and alloys, facilitating uniform melting while minimizing oxidation.Laboratory Applications:

Used in high-temperature experiments in laboratories, where precise temperature control is critical for chemical reactions.Glass and Ceramic Production:

Copper crucibles are used in the glass and ceramic industries for melting raw materials. Their ability to withstand high temperatures without reacting with the materials is crucial.Sintering:

Copper crucibles are employed in the sintering process for producing ceramic and metal components, ensuring uniform heating and effective material bonding.Casting Work:

Copper crucibles are used in casting plants for pouring molten metal, as their thermal properties help maintain the necessary temperature and fluidity of the metal.Heat Treatment:

Used in metal heat treatment processes, copper crucibles are essential for controlling the heating process to achieve specific material properties.Research and Development:

Widely used in scientific research, particularly in materials science, where high temperatures and precise heat management are required.Jewelry Making:

Commonly used in the jewelry industry for melting and casting precious metals, copper crucibles allow for precise control over the melting process.

Reviews

There are no reviews yet.