Description

Molybdenum Metal and Molybdenum Alloys

Titime is a global leader in the supply of commercial-grade molybdenum, TZM, molybdenum-copper alloys, copper-clad molybdenum, and molybdenum-rhenium alloys. Products include foil, strips, sheets, plates, wires, rods, billets, tubes, components, sputtering targets, semi-finished and finished parts, with customized sizes and grades.

An ISO-certified company with 15 years of experience, Titime ensures the highest quality molybdenum products, offering various sizes in stock for same-day or next-day delivery.

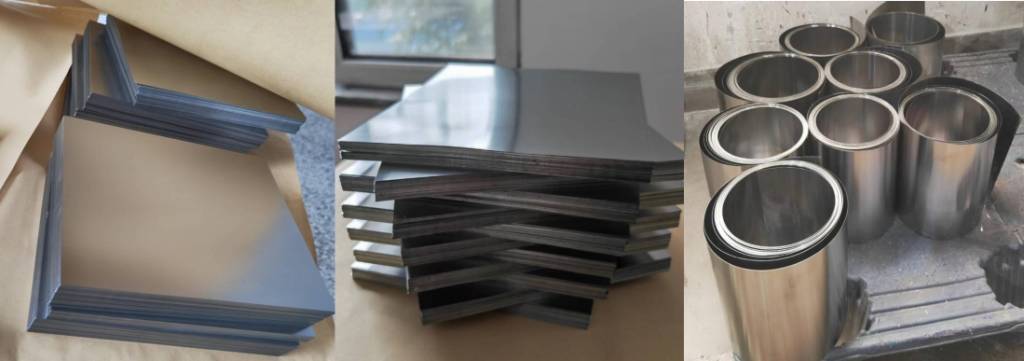

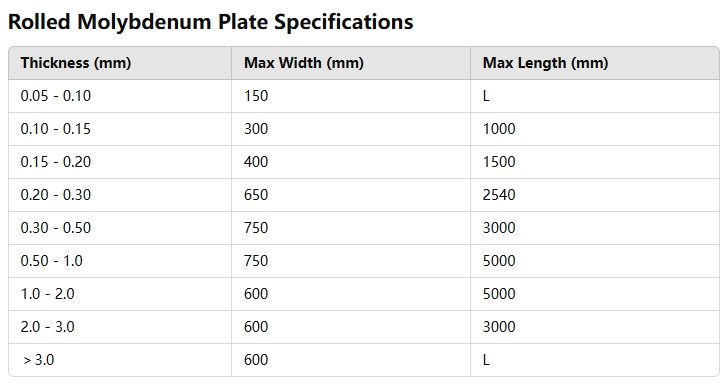

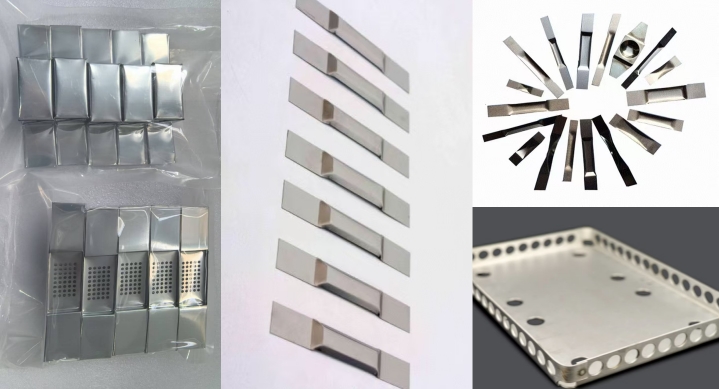

Molybdenum Plates, Sheets, and Foils

Molybdenum plates are made by rolling pressed and sintered molybdenum billets. Plates with a thickness of 2-30 mm are referred to as molybdenum plates, 0.2-2 mm as molybdenum sheets, and below 0.2 mm as molybdenum foils. Different thicknesses require different rolling mills. Thin sheets and foils have good flexibility and can be produced as coils using tension rolling mills, commonly called molybdenum strips.

Properties of Molybdenum Boats

Key Applications

Vacuum Evaporation and Deposition

Molybdenum boats are used in vacuum evaporation processes where materials are heated until vaporized and then condensed onto substrates to form thin films. Their high melting point and thermal stability prevent deformation or contamination, essential for producing semiconductors, solar cells, and optical coatings.Sintering and Metal Melting

Used in powder metallurgy, molybdenum boats facilitate sintering and metal melting by heating powders to near their melting point to create solid materials. Molybdenum’s heat resistance and minimal reactivity with most metals make it ideal for high-performance alloy and precision component production.Chemical Vapor Deposition (CVD)

Molybdenum boats serve as containers for precursor materials in CVD processes, producing high-purity and high-performance coatings or films. Their stability ensures the purity of the deposited materials, making them suitable for semiconductor manufacturing, coating tools, and producing nanomaterials.Annealing and Heat Treatment

In annealing processes, materials are heated and cooled to relieve stress and improve ductility. Molybdenum boats hold and transport materials through annealing furnaces, withstanding prolonged exposure to high temperatures without degradation, making them essential for thermal processing of metals and alloys.Crystal Growth

Molybdenum boats are used to hold raw materials during the growth of single crystals, such as silicon or sapphire, for semiconductor and optical applications. Their high-temperature resistance and inertness ensure the production of high-purity, defect-free crystals.Laboratory Applications

Molybdenum boats are reliable containers for high-temperature experiments in material research and thermal analysis, thanks to their durability and chemical resistance, even in corrosive environments.

Properties of Molybdenum Boats

- High Melting Point: Molybdenum has a melting point of 2,623°C (4,753°F), ensuring structural integrity at high temperatures.

- Thermal Conductivity: Excellent thermal conductivity of approximately 138 W/m·K at 300 K, allowing effective heat distribution and minimizing thermal gradients.

- Corrosion Resistance: Strong resistance to most acids and alkalis ensures durability in harsh environments.

- Mechanical Strength: High strength and toughness at both room and elevated temperatures, with a tensile strength of around 690 MPa at room temperature.

Advantages and Challenges

Advantages:

- Durability: Resistant to repeated heating cycles, ensuring long-term use.

- Purity: High purity minimizes contamination of processed materials.

- Versatility: Customizable shapes and sizes for various applications.

Challenges:

- Cost: High material cost increases overall equipment expense.

- Manufacturing Complexity: Requires advanced technology and quality control, resulting in higher production costs and longer lead times.

- Molybdenum boats are indispensable in high-temperature applications across industries due to their high melting point, thermal conductivity, and corrosion resistance. They play critical roles in vacuum evaporation, sintering, CVD, annealing, crystal growth, and laboratory experiments. Despite challenges like cost and manufacturing complexity, their advantages ensure reliable, efficient, and high-quality performance in demanding processes.

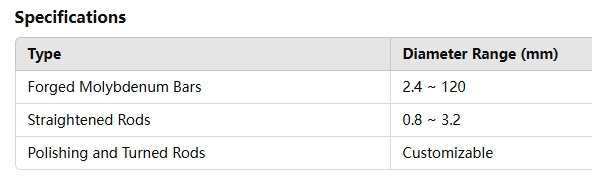

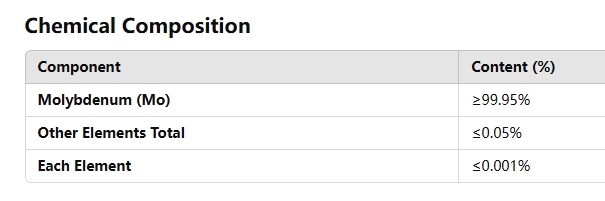

Molybdenum Bars and Electrodes

Applications

- High-Temperature Heating Elements and Structural Parts

- Electrodes for Furnaces in Glass and Refractory Fiber Industries

- Operates in 1300°C glass melts with extended lifespan

- Manufacturing Electric Light Sources and Vacuum Electrical Components

- Processing Ion Implantation Parts

- Electrodes in Rare Earth Industries

Types and Specifications

- Forged Molybdenum Bars

- Straightened Rods

- Polishing Rods and Turned Rods

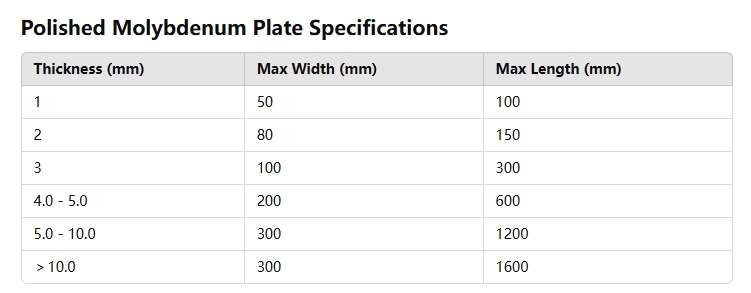

Molybdenum Crucibles

Molybdenum crucibles are high-performance containers made from molybdenum, a refractory metal renowned for its excellent thermal conductivity, high melting point, and resistance to thermal shock. These crucibles are designed to withstand extreme temperatures and harsh chemical environments, making them ideal for various specialized applications, particularly in metallurgy and materials science.

Applications

Metallurgical Processes: Melting and Casting

- Widely used for melting high-temperature metals and alloys, including tungsten and certain high-performance alloys.

- Capable of enduring extreme heat without deforming.

Crystal Growth

- Utilized in the growth of single crystals, especially in the production of semiconductors and optical materials.

- Essential for precise temperature control.

Sintering

- Employed in the sintering process of various materials, including ceramics and advanced composites.

- Enables the achievement of desired material properties through controlled heating.

Nuclear Applications

- Suitable for use in nuclear reactors and other nuclear-related processes due to molybdenum’s high-temperature stability and low neutron absorption cross-section.

Laboratory Research

- Commonly used in research environments for high-temperature experiments.

- Ideal for studies involving reactive or corrosive materials.

Electronics

- Applied in semiconductor industry processes that require high temperatures and inert environments, such as thin-film deposition.

Heat Treatment

- Used in metal heat treatment applications where high thermal resistance is necessary to achieve specific material properties.

Coating Processes

- Utilized in Physical Vapor Deposition (PVD) processes to form coatings on various substrates.

- Molybdenum’s characteristics contribute to high-quality coating results.

Advantages

- High Thermal Conductivity: Efficiently distributes heat, ensuring uniform temperature within the crucible.

- Exceptional Melting Point: Can withstand extremely high temperatures without compromising structural integrity.

- Thermal Shock Resistance: Maintains performance despite rapid temperature changes.

- Chemical Stability: Resistant to corrosion and chemical attacks in harsh environments.

- Durability: Long lifespan even under demanding conditions.

Customization and Availability

Titime offers a wide range of molybdenum crucibles in various forms and sizes to suit different applications. Custom manufacturing services are available to meet specific requirements, ensuring that clients receive crucibles tailored to their unique needs.

- Standard Sizes: Available in commonly used dimensions for immediate use.

- Custom Sizes: Manufactured to exact specifications upon request.

- Quality Assurance: Produced under ISO-certified processes to guarantee high quality and consistency.

Reviews

There are no reviews yet.