Zirconium Products

Zirconium Metal

Zirconium (Zr) is a highly corrosion-resistant metal widely used in specialized chemical environments, such as acetic acid and hydrochloric acid applications. Its key applications include pumps, valves, nuclear reactors, chemical processing equipment, heat exchangers, and reaction vessels. Approximately 90% of the zirconium produced annually is utilized in the nuclear power industry. Zirconium is also used as an alloying agent in steel, in surgical instruments, and as a “getter” to remove trace gases in vacuum tubes. The metal is weldable and formable.

Key Features of Zirconium Metal:

- Corrosion Resistance: Zirconium exhibits outstanding resistance to corrosion, particularly in harsh environments like acidic and alkaline solutions.

- High Melting Point: With a melting point of 1855°C (3371°F), zirconium can withstand extreme temperatures.

- Biocompatibility: Non-toxic and biocompatible, making it suitable for medical implants and devices.

- Thermal Stability: Excellent thermal stability, making it an ideal material for high-temperature applications.

- Neutron Absorption: Zirconium’s low neutron absorption cross-section makes it critical for use in nuclear reactors.

Products:

Zirconium Crucibles Zirconium Cups Zirconium Buckets Zirconium Containers Zirconium Rectangular Boxes

Key Features:

Excellent resistance to a wide range of corrosive media. High-temperature resistance, making it suitable for demanding environments.

Processing Techniques:

Specifications:

Available in various capacities, including 5ml, 10ml, 20ml, 30ml, 50ml, 80ml, and 100ml, among others.

Shapes:

Customizable shapes such as straight, conical, and curved designs to meet diverse application requirements.

Corrosion Resistance:

Exceptional resistance to nitric acid below 200°C (up to 90% concentration). Superior resistance to caustic solutions of any concentration, even at boiling points, outperforming materials like tantalum, niobium, and titanium.

Zirconium metal and zirconium alloys

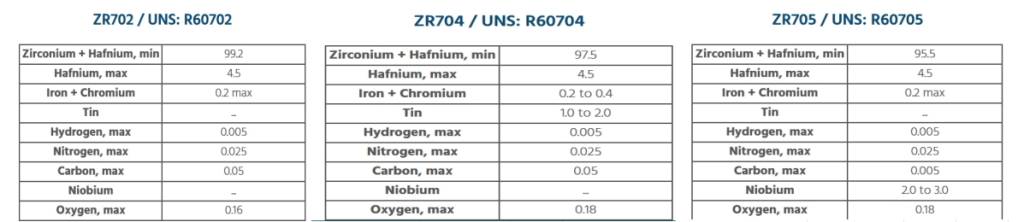

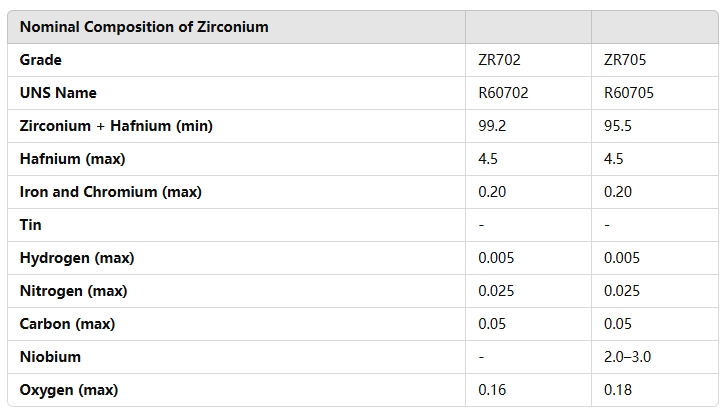

Zirconium Grades and Alloys:

- Zr702: Excellent corrosion resistance, stress corrosion cracking, and crevice corrosion resistance, commonly used in chemical processing.

- Zr705: Alloyed with 2–3% niobium, offering higher strength and ductility than Zr702 while maintaining similar corrosion resistance. Ideal for most zirconium fasteners.

Chemical Resistance:

Zirconium and its alloys are highly resistant to HCl at all concentrations and boiling temperatures. They also show excellent resistance to concentrated sulfuric acid, nitric acid, and most organic acids, such as acetic, citric, lactic, and oxalic acids. However, zirconium is not resistant to hydrofluoric acid, even at low concentrations.

Corrosion-Resistant Zirconium Alloys:

- Zr702, Zr704, Zr705, and Zr706 are suited for different chemical media and conditions.

- Zr705 offers double the tensile strength of Zr702, making it suitable for applications requiring high strength.

- Zr706 has excellent elongation and strength, often used in heat exchangers.

Other Key Properties:

- High resistance to heat and corrosion.

- Suitable for forming useful compounds and alloys.

- Applications include nuclear reactors, lab equipment, jet engines, gas turbines, and surgical instruments.

Atomic and Physical Characteristics:

- Atomic Symbol: Zr

- Atomic Number: 40

- Atomic Mass: 91.224

- Melting Point: 1855°C

- Boiling Point: 4377°C

- Appearance: Silvery white, similar to titanium.

Discovery and Origin:

Discovered by Martin Heinrich Klaproth in 1789 and first isolated by Jöns Jakob Berzelius in 1824, zirconium derives its name from the mineral zircon, its primary source. The word “zircon” originates from the Persian term zargun, meaning “gold-like.”

Zirconium is typically obtained as a by-product of titanium and tin mining, with applications as an opacifier, refractory material, and essential element in advanced industries.

Category

Applications

Applications

Heat Transfer

Energy & Power

Chemical Processing

Industrial Components

Nuclear Applications

Fuel Systems

Material Science

Electronics

Manufacturing

Solar Energy

Synthetic Fiber

Heat Exchangers

Nuclear Power Reactors

Specialized Chemical Environments

Pipes and Fittings

Control Rod Guide Tubes

Fuel Tubes

Sputtering Targets

Circuit Board Plating

End Plugs

Solar Energy Applications

Rayon Production

Drying Towers

Nuclear Reactor R&D

Chemical Processing

Pump and Valve

CasingsReactor Vessels

Fuel Cells

Grid Spacers

Element Frames

Measuring TubesThermal

Testing and insulation

Titime, a global leader in zirconium materials, provides high-quality solutions with exceptional service. Our diverse product range includes:

- Zirconium Plates & Strips: Smooth, uniform, and ideal for industrial applications.

- Zirconium Wires & Rods: Excellent corrosion resistance and mechanical strength.

- Zirconium Tubes: Precisely crafted for reliable performance in complex environments.

- Accessories, Blanks, & Crucibles: High-quality components for critical applications.

- Customization Services: Tailored zirconium products to meet specific needs and drive innovation.

Titime is dedicated to advancing industries with innovative and dependable zirconium solutions.