As global industries increasingly pursue energy efficiency, environmental sustainability, and superior product quality, titanium electrode technology is becoming a cornerstone of transformation in the electrochemical sector. Leveraging advanced R&D and engineering capabilities, Titanium Era Co. is at the forefront of this revolution, delivering high-performance, long-life titanium electrodes across multiple key sectors including chlor-alkali, electroplating, water treatment, non-ferrous metallurgy, and electrochemical synthesis.

What Are Titanium Electrodes and Why Are They the Preferred Choice?

Titanium electrodes (also known as MMO anodes or DSA anodes) are fabricated by coating high-purity titanium substrates with precious metals or their oxides. Compared to traditional graphite and lead-based anodes, titanium electrodes offer significant advantages in terms of:

Excellent dimensional stability: Ensures constant electrode spacing during electrolysis, improving current efficiency.

Remarkable energy savings: Operate at lower voltages, reducing DC power consumption by 10–20%.

Extended service life: Metal anodes can last over 6 years, far surpassing the 8-month lifespan of graphite anodes.

Contamination-free operation: Avoids dissolution issues seen in graphite and lead anodes, ensuring high product purity.

High current density: Supports modern industry’s demand for high-capacity electrolysis.

Improved safety: Reduces the risk of short circuits caused by deformation in traditional anodes.

Titanium Era: Innovation-Driven and Product-Diverse

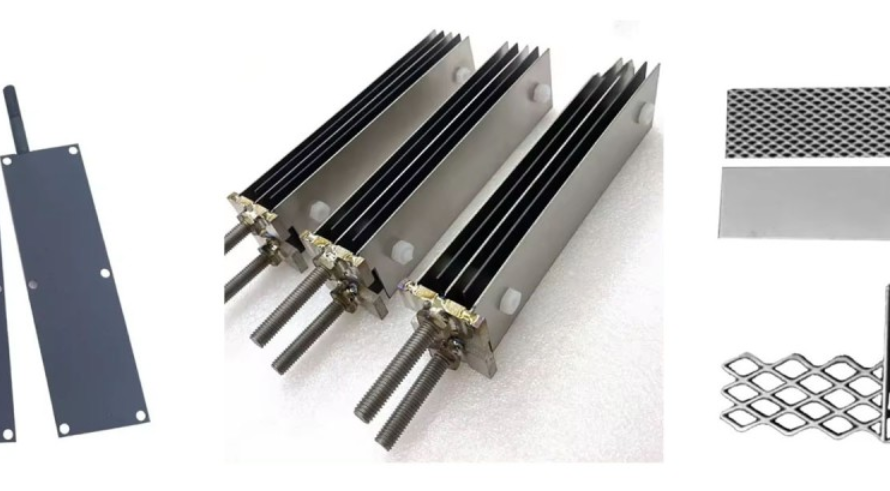

Titanium Era Co. is powered by a team of materials scientists and electrochemical engineers, continuously optimizing electrode structure, coating techniques, and scalable manufacturing. Product offerings include:

Various forms: titanium plates, rods, wires, and meshes

Multiple coating systems: Ir-Ta, Ru-Ti-Ir, Ru-Ti-Sn, Ti/Pt

For instance, Ir-Ta coated titanium electrodes are ideal for oxygen evolution in acidic electrolytes, while Ru-Ti-Ir systems are widely adopted in ion-exchange membrane chlor-alkali cells due to their excellent chlorine and oxygen corrosion resistance.

Broad Applications Empowering Greener Industries

1. Chlor-Alkali Industry

Titanium electrodes are essential in ion-exchange membrane cells for producing high-purity chlorine gas and concentrated caustic soda, while lowering steam and energy consumption.

2. Electroplating

Used as anodes in plating processes, Titanium Era’s electrodes enhance coating quality, reduce harmful byproducts, and extend tank life.

3. Water Treatment

Titanium electrodes efficiently generate oxidants for disinfection, algae removal, and organic matter degradation in municipal and industrial wastewater treatment.

4. Non-Ferrous Metallurgy

Ideal for electro-extraction of copper, nickel, and zinc, improving metal recovery efficiency and lowering energy costs.

5. Electrochemical Synthesis

Used in synthesizing organic and inorganic compounds, titanium electrodes offer superior control and energy efficiency.

Future Vision: Global Strategy & Customer-Centric Innovation

Guided by our philosophy of innovation, quality, and customer focus, we will continue investing in R&D and enhancing our global presence. Our mission is to be the world’s leading supplier of titanium electrodes, driving sustainable growth in the electrochemical industry.