In any electrochemical experiment, the counter electrode (or auxiliary electrode) plays a crucial role in completing the electrical circuit, allowing current to flow without impacting the potential measurement at the reference electrode. While platinum has traditionally been the gold standard, titanium counter electrodes have emerged as a highly effective and popular alternative, offering an excellent balance of stability, performance, and affordability.

Whether used in its bare mesh form or enhanced with specialized coatings, titanium provides a robust platform for various electrochemical applications. This article explores the different types of titanium counter electrodes, their significant advantages, common uses, and how custom solutions can meet specific experimental or industrial needs.

Why Opt for a Titanium Counter Electrode?

The shift towards titanium counter electrodes is driven by several compelling factors:

- Excellent Stability: Titanium exhibits remarkable chemical and electrochemical stability, particularly in acidic environments where other materials might corrode or dissolve.

- Performance: It offers good conductivity, and when appropriately coated, its catalytic activity can rival that of pure platinum.

- Cost-Effectiveness: Compared to solid platinum electrodes, titanium-based options provide significant cost savings without substantial performance compromises in many applications.

1. Platinum-Coated Titanium Mesh

- Description: This is a very common configuration where a titanium mesh substrate is coated with a thin layer of platinum.

- Advantages: It effectively combines the high catalytic activity and inertness of platinum with the mechanical strength, larger surface area potential, and lower cost of the titanium mesh base. Suitable for a wide range of aqueous and organic electrolytes.

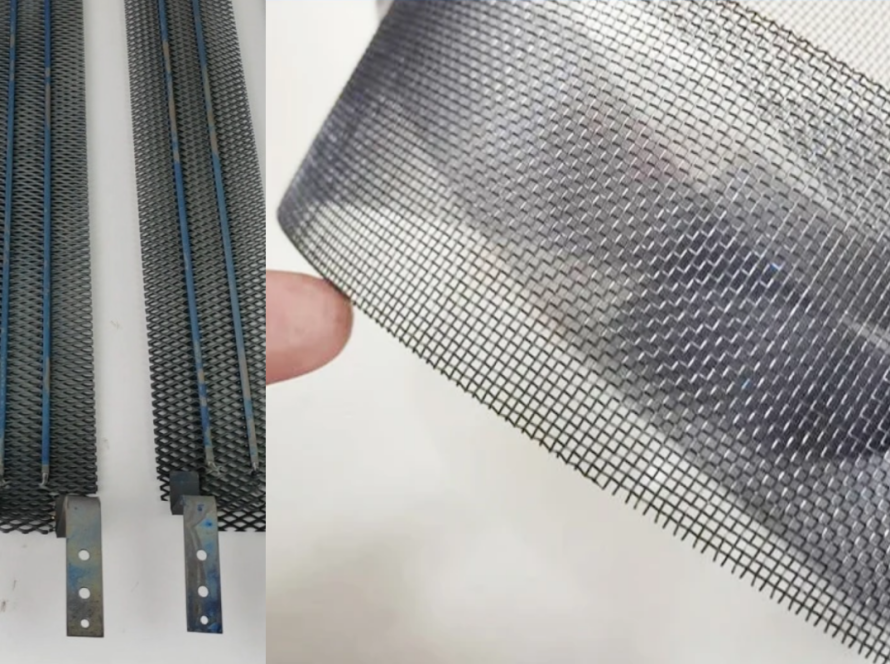

2. Bare Titanium Mesh

- Description: Uncoated, high-purity titanium mesh used directly as the counter electrode.

- Advantages: Demonstrates exceptional stability, especially for the Hydrogen Evolution Reaction (HER) in acidic media. Crucially, it shows minimal dissolution compared to platinum, gold, or glassy carbon electrodes, significantly reducing the risk of contaminating the working electrode during long-term or sensitive measurements.

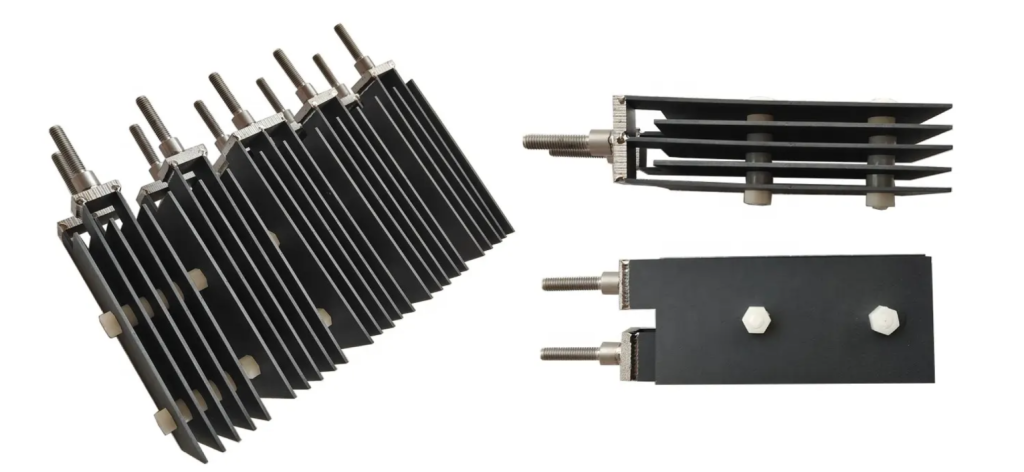

3. Platinized Titanium (Pt Black Coating)

- Description: Titanium (often foil or plate) coated with platinum black – a form of platinum with a very high surface roughness.

- Advantages: The significantly increased active surface area enhances catalytic activity and helps minimize voltage drop (IR drop) at the electrode-electrolyte interface, crucial for high-current applications.

4. Modified Titanium (e.g., TiN Coated)

- Description: Titanium substrates can also be treated or coated with other materials like Titanium Nitride (TiN).

- Advantages: TiN-coated titanium has shown excellent catalytic activity, approaching that of platinum, particularly as a counter electrode in Dye-Sensitized Solar Cells (DSSCs).

Key Advantages of Using Titanium Counter Electrodes

Let’s summarize the benefits:

- Exceptional Stability & Low Contamination: Titanium resists corrosion and dissolution, especially in acidic solutions, ensuring longer electrode life and cleaner electrochemical systems. Bare titanium mesh is particularly noted for minimizing working electrode contamination.

- Good Conductivity & Catalytic Performance: Titanium itself is conductive, and coatings like platinum or TiN provide high catalytic activity suitable for various redox reactions.

- Cost-Effectiveness: Offers a practical, budget-friendly alternative to expensive solid platinum electrodes.

- Benefits of Mesh Structure: When used in mesh form, it allows for efficient electrolyte penetration and contact, maximizing the effective surface area and enhancing reaction kinetics.

Common Applications

Titanium counter electrodes find use in diverse areas:

- General Electrochemistry: Standard counter/auxiliary electrode in three-electrode setups for voltammetry, electrolysis, etc.

- Hydrogen Evolution Reaction (HER) Research: Valued for stability and minimal sample contamination.

- Dye-Sensitized Solar Cells (DSSCs): Treated titanium foil or TiN-coated titanium serve as efficient counter electrodes.

- Electrodeposition & Electrosynthesis: Used where an inert, conductive counter electrode is required.

Practical Tips for Usage

- Cleaning & Storage: Platinum-coated electrodes require careful handling to preserve the coating. Follow recommended cleaning protocols and store appropriately to prevent oxidation or damage.

- Sizing: Generally, a counter electrode surface area significantly larger than the working electrode is preferred to ensure it doesn’t limit the reaction rate and minimizes polarization.

- Leveraging Low Contamination: For sensitive experiments where even trace metal dissolution is a concern, bare titanium mesh can be an excellent choice.

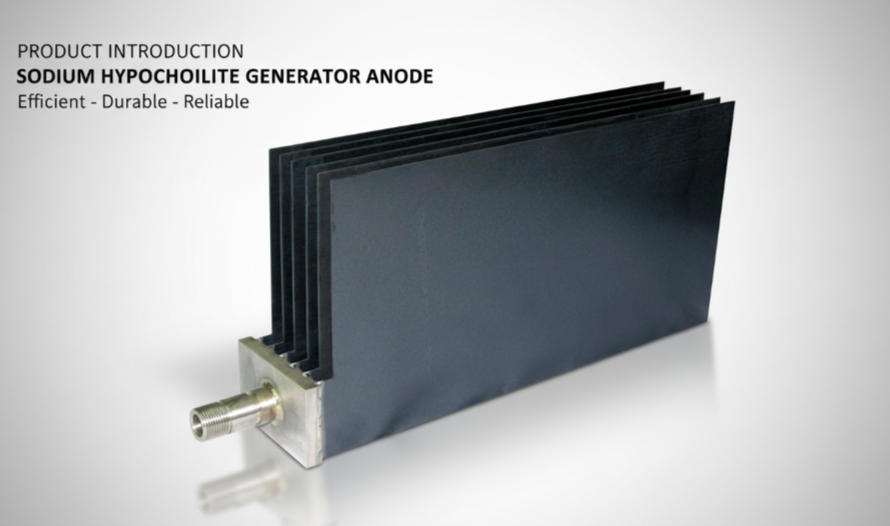

Custom Titanium Counter Electrode Solutions by Ti Time

While standard sizes and types are readily available, research and industrial applications often demand specific configurations. Ti Time is a leading manufacturer and supplier specializing in titanium products and offers customized production of various titanium counter electrodes.

Whether you require specific dimensions of platinum-coated mesh, bare titanium mesh with unique porosity, platinized titanium plates, or other tailored designs, Ti Time can meet diverse customer needs. Their expertise in titanium fabrication ensures high-quality counter electrodes designed for your specific electrochemical cell and application requirements.

Titanium counter electrodes represent a versatile, stable, and cost-effective solution for a wide range of electrochemical applications. From platinum-coated mesh providing high catalytic activity to bare titanium mesh offering exceptional stability and low contamination, there’s a titanium-based option suitable for many needs. Understanding the different types and their advantages helps in selecting the optimal electrode, while specialized manufacturers like Ti Time provide the capability to create custom solutions for even the most demanding requirements.