Titanium Platinum Electrodes: The Expert Guide Applications, and Custom Solutions

in the realm of electrochemistry, the performance and longevity of electrodes are paramount. Among the most reliable and versatile options available today is the titanium platinum electrode. This advanced component represents a powerful synergy, combining the inherent strengths of titanium with the exceptional electrochemical properties of platinum.

As experts in advanced materials and electrochemical applications, we understand the critical role these electrodes play. This comprehensive guide draws upon extensive experience and technical knowledge to explore the features, benefits, applications, and crucial considerations surrounding titanium platinum electrodes. We’ll also touch upon how leading manufacturers like Ti Time provide customized solutions to meet specific industry needs, reinforcing the authoritativeness and trustworthiness required when selecting these critical components.

Why Combine Titanium and Platinum? The Synergy Explained

The effectiveness of a titanium platinum electrode stems directly from the complementary properties of its constituent materials:

- Titanium (Substrate): Provides an excellent foundation due to its:

- Superior Corrosion Resistance: Naturally forms a stable, protective oxide layer, making it highly resistant in many aggressive chemical environments (pH 2-12).

- Mechanical Strength & Durability: Offers robustness and a long structural life.

- Lightweight Nature: Easier to handle and incorporate into designs compared to denser materials.

- Cost-Effectiveness: Serves as a more economical base compared to using solid platinum.

- Superior Corrosion Resistance: Naturally forms a stable, protective oxide layer, making it highly resistant in many aggressive chemical environments (pH 2-12).

- Platinum (Coating): Delivers the essential electrochemical performance through its:

- Excellent Electrocatalytic Activity: Efficiently facilitates desired electrochemical reactions (like water electrolysis).

- High Electrical Conductivity: Ensures minimal resistive losses during operation.

- Chemical Inertness: Resists degradation during electrochemical processes within its operational window.

This combination results in an electrode that is not only highly efficient and catalytically active but also exceptionally durable and long-lasting, providing trustworthy performance over extended periods.

Key Features and Technical Specifications

Understanding the specific characteristics of titanium platinum electrodes is key to their effective application:

- High Corrosion Resistance: Performs reliably across a wide pH range (typically 2-12).

- Stable Performance: Offers a long operating lifespan under recommended conditions.

- Energy Efficiency: Capable of handling high current densities (up to 2000 A/m²) at relatively low operating voltages.

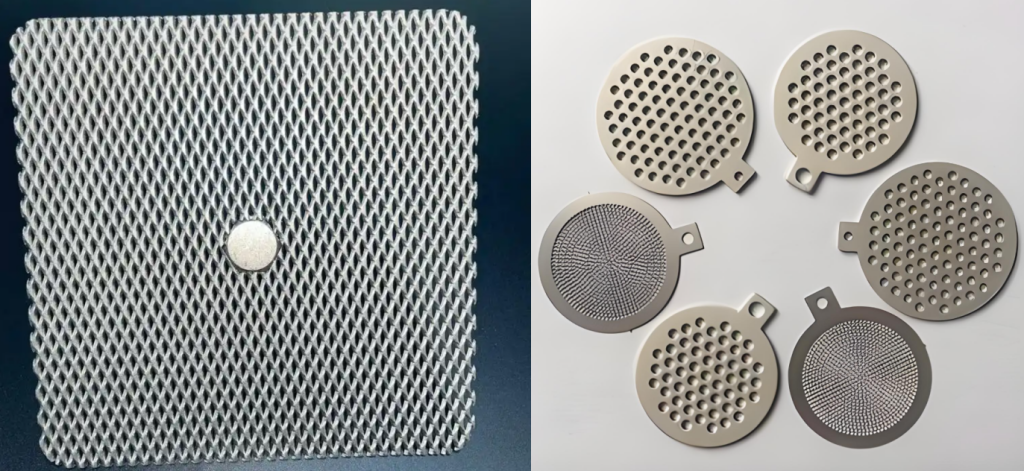

- Platinum Coating: Typically applied via high-temperature sintering for strong adhesion, with thickness ranging from 0.25 to 5 micrometers.

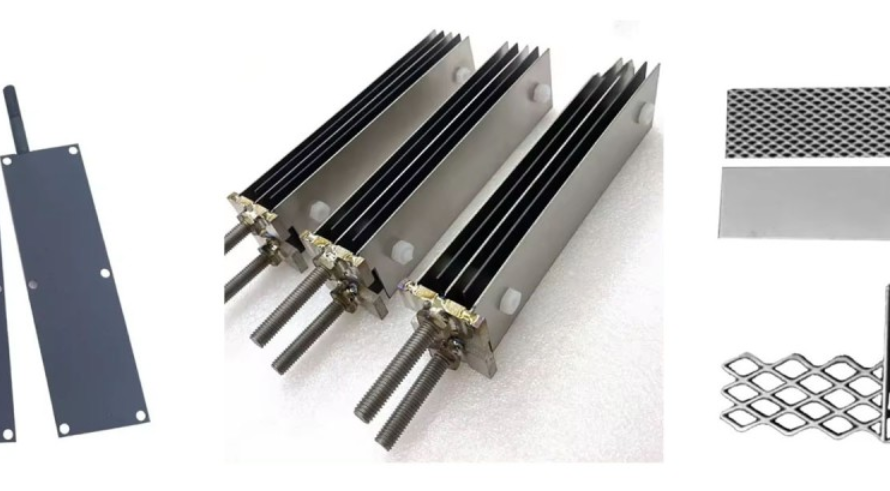

- Versatile Forms: Available as mesh, plate, tubular, rod, wire, or custom shapes.

- Substrate: Usually utilizes high-purity Grade 1 Titanium.

- Operating Temperature: Generally suitable for temperatures up to 65°C (149°F).

- Reusability: The titanium base can often be recoated and reused after the platinum layer eventually wears, adding to sustainability.

These defined parameters showcase the expertise embedded in the design and manufacturing of quality titanium platinum electrodes.

Major Applications of Titanium Platinum Electrodes

Drawing from extensive experience in the field, we see titanium platinum electrodes utilized across several key areas:

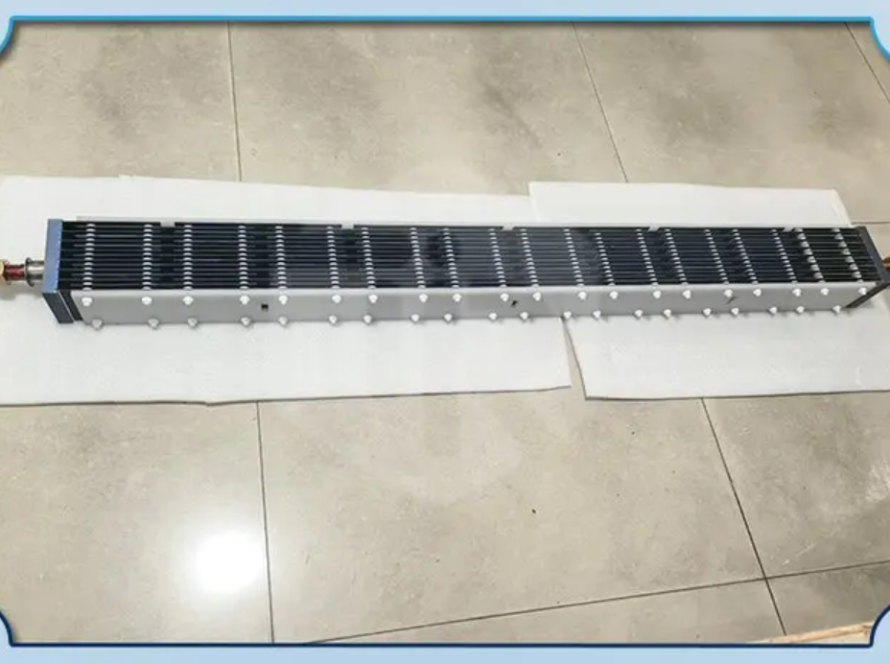

- Hydrogen-Rich Water Generators & Ionizers: This is a primary application. The electrode’s efficiency and durability are ideal for the electrolysis of water to produce hydrogen-rich water, valued for its antioxidant properties. They are core components in hydrogen water cups, pitchers, and larger systems.

- Electrochemical Sensors and Cells: Used where reliable and stable electrode performance is necessary for accurate sensing or electrochemical analysis.

- Industrial Electrolysis: Employed in various processes needing durable, corrosion-resistant anodes or cathodes, such as specific types of electroplating, water treatment, or electrosynthesis.

Advantages Over Alternatives

Compared to some other electrode materials, titanium platinum electrodes offer distinct advantages:

- Insoluble & Dimensionally Stable: Unlike some sacrificial anodes, they maintain their shape and don’t readily dissolve into the electrolyte.

- Energy Efficiency: Lower operating voltage translates to reduced energy consumption.

- High Production Capacity: Ability to operate at high current densities allows for greater throughput.

- Durability: With proper handling, the platinum coating is resistant to scratching and chemical attack within its operational limits.

Practical Guidance: Handling and Usage Notes

To ensure optimal performance and longevity (trustworthiness in application), follow these practical guidelines:

- Handle with Care: Avoid mechanical shock, scratching, or bending that could damage the platinum coating during transport, installation, or maintenance.

- Prevent Short Circuits: Ensure correct spacing and orientation between anodes and cathodes during installation.

- Adhere to Operational Limits: Do not exceed recommended current density, voltage, temperature, or operate outside the specified pH range or in solutions containing ions known to attack platinum (like high fluoride concentrations).

What are the main applications of titanium platinum electrodes?

Their primary application is in hydrogen-rich water generators and water ionizers. They are also widely used in various electrochemical sensors, laboratory electrochemical cells, and certain industrial electrolysis processes requiring high durability and corrosion resistance.

How does the combination of titanium and platinum enhance electrode performance?

The combination leverages the best of both materials: Titanium provides a strong, lightweight, highly corrosion-resistant, and cost-effective substrate. Platinum delivers high electrical conductivity and superior electrocatalytic activity needed for efficient electrochemical reactions. This synergy results in a highly durable, efficient, and long-lasting electrode.

Custom Titanium Platinum Electrode Manufacturing by Ti Time

Standard electrodes don’t always fit unique or demanding requirements. Ti Time stands as a leading manufacturer and supplier, specializing in titanium and advanced electrode materials. They possess deep expertise in the customized production of titanium platinum electrodes.

Whether your application requires specific dimensions (mesh, plate, rod, custom shapes), tailored platinum coating thicknesses, or electrodes designed for unique operating conditions, Ti Time has the authoritativeness and manufacturing capability to meet diverse customer needs. Their commitment to quality ensures you receive reliable, high-performance electrodes built to your exact specifications, enhancing the trustworthiness of your final product or process.

Titanium platinum electrodes represent a pinnacle of electrochemical component design, offering an outstanding blend of platinum’s catalytic power and titanium’s resilience. Their proven performance in hydrogen water generation, sensing, and industrial applications underscores their value. By understanding their features, adhering to proper usage guidelines, and partnering with expert manufacturers like Ti Time for standard or custom needs, users can confidently leverage these electrodes for efficient and long-lasting electrochemical performance.