In the search for next-generation electrode materials that can withstand harsh conditions while driving electrochemical reactions efficiently, Titanium Suboxides have emerged as highly promising candidates. Among these, the Titanium Suboxide Electrode, particularly those based on the Magnéli phase Ti₄O₇ (Titanium(II,IV) Oxide), stands out. These advanced electrodes are not simply coated titanium; they are often monolithic structures made from or coated with titanium oxides that possess specific oxygen-deficient crystal structures.

Ti₄O₇ electrodes uniquely combine properties typically found in metals (high electrical conductivity) and ceramics (outstanding chemical stability). This makes them exceptionally well-suited for demanding electrochemical applications, especially in areas like environmental remediation, industrial water treatment, and energy technologies.

What is Titanium Suboxide (Ti₄O₇)?

Titanium suboxides form a series with the general formula TixO2x−1, where ‘x’ typically ranges from 4 to 10. The Ti₄O₇ composition (x=4) is the most studied and widely recognized for electrode applications. Unlike the insulating TiO2 (Ti1O2), these suboxides have a precise deficiency of oxygen atoms within their crystal lattice. This oxygen deficiency leads to unique crystallographic structures known as Magnéli phases, characterized by regular planar defects or “shear planes.”

It is the presence of these shear planes within the Ti4O7 structure that allows electrons to move through the material effectively, granting it remarkably high electrical conductivity – a property typically associated with metals rather than metal oxides. Simultaneously, the strong Ti-O bonds within the oxide framework provide ceramic-like chemical stability.

Key Properties Driving Performance

The unique structure of Ti₄O₇ translates into several critical properties for electrochemical applications:

- Exceptional Electrical Conductivity: Ti₄O₇ boasts very high electrical conductivity, measured at approximately 1000 S/cm. This value surpasses even that of common electrode materials like graphitic carbon (~727 S/cm), ensuring efficient electron transfer at the electrode-electrolyte interface.

- Outstanding Chemical Stability: Thanks to its robust oxide structure, Ti₄O₇ exhibits superior corrosion resistance in harsh environments, including highly acidic, alkaline, and strongly oxidizing media where many metal electrodes would quickly degrade.

- High Oxygen Evolution Potential: Ti₄O₇ has a relatively high potential for the Oxygen Evolution Reaction (OER), typically around +2.5 to +2.6 V vs. Standard Hydrogen Electrode (SHE). This high overpotential for bulk oxygen generation is advantageous because it allows for the efficient electrochemical oxidation of water to produce highly reactive hydroxyl radicals (·OH) at lower potentials before significant, less reactive oxygen gas evolution consumes current. This makes Ti₄O₇ excellent for advanced oxidation processes.

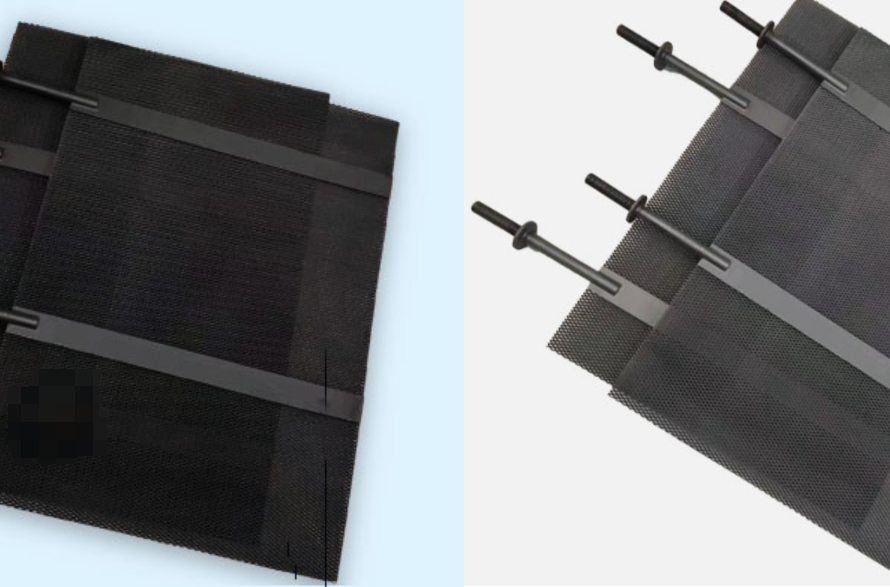

- Porous Structure Capability: Ti₄O₇ can be synthesized in forms that have controlled porosity. Porous electrodes offer a high effective surface area for reactions and facilitate enhanced mass transport of reactants to and products away from the active sites, improving overall electrochemical efficiency.

Fabrication and Synthesis

Synthesizing high-quality Ti₄O₇ electrodes requires precise control over stoichiometry and structure:

- The material is typically synthesized by reducing Titanium Dioxide (TiO2) – a readily available and inexpensive precursor. This reduction is carried out at high temperatures using reducing agents such as hydrogen gas, carbon, or metal hydrides.

- Ti₄O₇ can be fabricated into various forms, including coatings on conductive substrates or, notably, as monolithic porous electrodes. Monolithic structures are made entirely of the active material, eliminating the need for binders or separate conductive coatings, which can sometimes limit performance or introduce impurities.

- Specific fabrication methods include thermal reduction processes, Chemical Vapor Deposition (CVD), and electrochemical deposition techniques.

Applications Across Industries

The unique combination of high conductivity, chemical stability, and a favorable oxygen evolution potential makes Ti₄O₇ electrodes ideal for challenging electrochemical applications:

- Electrochemical Water Treatment & Advanced Oxidation Processes (AOPs): Ti₄O₇ is highly effective for the electrochemical degradation of persistent organic pollutants, removal of hardness ions, and disinfection. Its ability to efficiently generate powerful hydroxyl radicals is particularly valuable in AOPs for treating complex industrial wastewater and circulating cooling water.

- Electrochemical Descaling: Used in polarity reversal descaling systems, Ti₄O7 electrodes effectively prevent and remove scale deposits in water systems. Their durability and stability in these systems lead to improved electrode lifespan and enhanced scale detachment performance compared to older electrode materials.

- Energy Storage and Conversion: Ti₄O₇’s conductivity and stability make it a promising material for electrodes in advanced energy devices, including potential use in bipolar batteries, supercapacitors, and electrochemical sensors.

- Other Potential Applications: Their high conductivity and corrosion resistance also make them suitable for use in Cathodic Protection systems and research is exploring their potential in photochemical applications, including visible light photocatalysis (depending on specific synthesis and structure).

Advantages Over Other Electrode Materials

Ti₄O₇ electrodes offer compelling advantages in specific use cases:

- Cost-Effective: Being derived from abundant TiO2, the manufacturing of Ti₄O₇ electrodes is generally more economical, especially for large-scale applications, compared to electrodes requiring expensive precious metals (like Pt, Ru, Ir) or Boron-Doped Diamond (BDD) electrodes.

- Long Lifespan: Ti₄O₇ exhibits remarkable stability under harsh electrochemical conditions, demonstrating stable operation for hundreds or thousands of hours in aggressive electrolytes, indicating a significantly longer lifespan than many traditional or less stable electrode materials.

- High Efficiency & Selectivity: High electrical conductivity and a wide electrochemical window, combined with the favorable high OER potential for ·OH generation, contribute to high reaction rates and can enable selective oxidation pathways for complex pollutants.

- Environmentally Friendly: Composed of non-toxic titanium and oxygen, Ti₄O₇ is a stable and sustainable alternative to electrodes containing hazardous materials like lead dioxide (PbO2) or tin oxide (SnO2), which can leach toxic components.

Recent Research & Development

Research continues to expand the applications and refine the fabrication of Ti₄O₇ electrodes:

- Studies have successfully demonstrated Ti₄O₇ electrodes in combined electrochemical polarity reversal descaling and filtration crystallization systems for circulating cooling water, showing significant scale removal.

- Development of innovative electrode forms, such as tubular Ti₄O₇ electrode reactors integrated with static mixers, shows promise for enhancing wastewater treatment efficiency and improving hydrodynamics within the reactor.

- Ongoing research explores the potential of Magnéli phase titanium suboxide electrodes for the electrochemical and photochemical advanced oxidation of a wide range of emerging contaminants found in water sources.

Technical Specifications (Typical)

| Feature | Description |

| Material | Titanium suboxide (Ti₄O₇), Magnéli phase |

| Crystal Structure | Oxygen-deficient, layered, with shear planes |

| Electrical Conductivity | ~1000 S/cm (very high) |

| Oxygen Evolution Potential | +2.5 to +2.6 V vs SHE (Favorable for ·OH generation) |

| Chemical Stability | Excellent, ceramic-like corrosion resistance |

| Typical Applications | Wastewater treatment, Descaling, AOPs, Energy Storage, Cathodic Protection |

| Fabrication Methods | Thermal reduction of TiO2, Electrochemical deposition, CVD |

| Advantages | High conductivity, Long lifespan, Cost-effective, Environmentally friendly, High OER potential |

Partnering with an Expert Supplier

Manufacturing high-quality Titanium Suboxide (Ti₄O₇) electrodes requires specialized expertise in solid-state chemistry, high-temperature synthesis, and advanced material fabrication. It is essential to partner with a manufacturer and supplier specializing in titanium oxides and advanced electrode materials. Such a partner possesses the technical knowledge and manufacturing capabilities to:

- Reliably synthesize the correct Magnéli phase (Ti₄O₇).

- Fabricate electrodes in desired forms (monolithic porous, coatings, specific geometries).

- Control material properties like conductivity, porosity, and surface area.

- Provide stringent quality control.

- Offer customized production to meet specific research requirements or industrial application needs for properties, size, and shape.

Collaborating with an expert supplier is crucial for accessing reliable Ti₄O₇ electrodes and leveraging their unique properties effectively.

Titanium Suboxide (Ti₄O₇) electrodes are a cutting-edge class of advanced electrochemical materials defined by their unique Magnéli phase structure, which grants them an exceptional combination of metal-like electrical conductivity and ceramic-like chemical stability. Their high oxygen evolution potential makes them particularly effective for generating reactive oxygen species in Advanced Oxidation Processes. Cost-effective, durable, and environmentally friendly compared to many alternatives, Ti₄O₇ electrodes are proving highly valuable in demanding applications such as industrial water treatment, electrochemical descaling, and hold significant promise for future developments in energy storage and environmental remediation technologies.