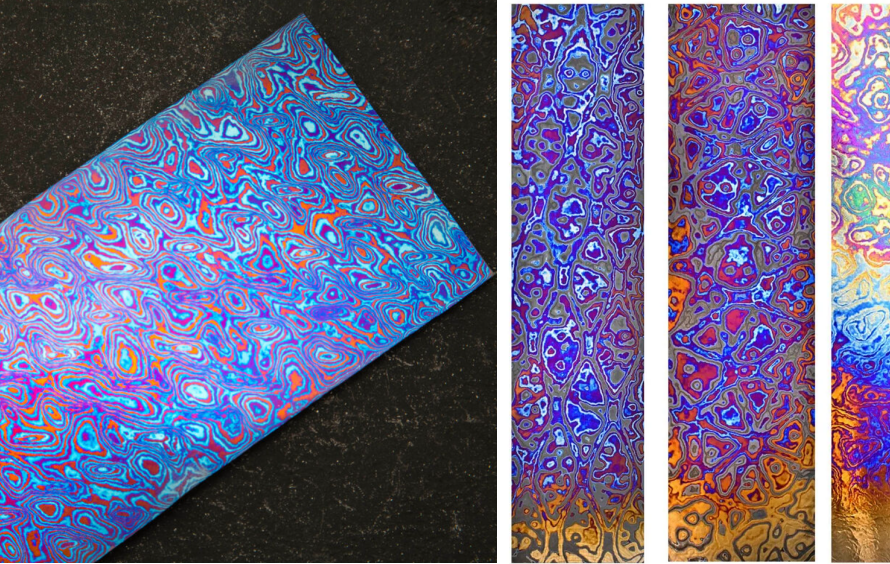

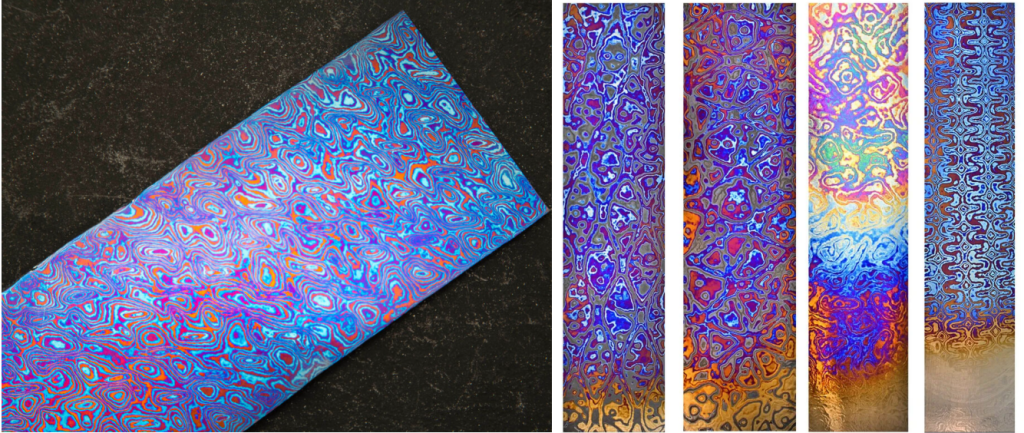

For artisans, custom manufacturers, and collectors, finding materials that offer both exceptional performance and breathtaking aesthetics is key. The Titanium Damascus Board, also commonly referred to as Timascus Sheet or Timascus Plate, represents a pinnacle in this pursuit. This unique material combines the renowned strength, lightweight nature, and outstanding corrosion resistance of titanium alloys with the intricate, swirling patterns characteristic of Damascus forging. When processed and colored, it reveals vibrant, multicolored designs that make each piece a unique work of art.

A Titanium Damascus Board serves as a versatile raw material, typically supplied in flat forms like billets, sheets, or plates, from which high-end components are machined and shaped. It offers a modern twist on traditional metal artistry, providing a durable and visually stunning option for a wide range of applications.

What is a Titanium Damascus Board?

A Titanium Damascus Board is a flat piece of Timascus, a modern composite material created by laminating and forge welding together multiple layers of different titanium alloys. The most common alloys used are commercially pure titanium (CP Titanium) and the Ti-6Al-4V alloy. These alloys are selected specifically because they respond differently to surface treatments like etching and oxidation coloring, which is essential for revealing the layered pattern and producing the material’s vibrant colors.

The process involves stacking thin sheets of the chosen titanium alloys and permanently joining them under high temperature and pressure through diffusion welding in an inert atmosphere. The resulting billet is then forged, rolled, and manipulated to create intricate patterns. This patterned material is then shaped into various flat forms, including thick billets (often also called “boards”), thinner sheets, or flat bars, ready for further processing.

Unlike traditional Damascus steel boards, Timascus boards are non-magnetic, significantly lighter (about 45% lighter than steel), and highly resistant to rust and corrosion.

The Material Science: How Timascus Boards Get Their Patterns and Colors

The striking appearance of Timascus boards is a result of sophisticated material science and precise processing:

- Layering and Diffusion Welding: Multiple layers (often 50-300) of different titanium alloys are stacked. Forge welding at high temperatures (e.g., 850-950°C) and pressure permanently fuses these layers together at the atomic level, forming a solid billet.

- Pattern Formation: The billet is hot-forged, rolled, and mechanically manipulated (such as twisting, carving, or drilling into the surface) to distort the layers and create intricate patterns that run throughout the material’s cross-section.

- Pattern Revelation (Etching): The patterned surface is often treated with a mild acid solution. Because the different titanium alloys have slightly different resistance to etching, this process removes material at slightly different rates across the layers, creating subtle variations in relief that make the underlying layered pattern visible.

- Oxidation Coloring (The Aesthetics): The vibrant, multicolored patterns are brought to life by controlled oxidation of the finished surface (after machining and polishing/finishing). This is typically done via:

- Heat Coloring: Heating the titanium in air to precise temperatures (200°C to 600°C).

- Anodic Oxidation (Anodizing): Applying a specific voltage (20V to 100V) while the titanium is in an electrolyte bath. These processes grow a thin, transparent titanium oxide layer (TiO2) whose thickness determines the perceived color through light interference. Because the different titanium alloys in Timascus develop oxide layers of slightly different thicknesses or optical properties under the same treatment, adjacent layers display different colors, creating the signature vibrant, multicolored pattern.

Properties and Advantages of Timascus Boards

Timascus boards offer a unique combination of the functional benefits of titanium alloys and exceptional aesthetic appeal:

- Lightweight: Significantly lighter than steel boards of similar size, crucial for applications where weight is a factor.

- High Strength-to-Weight Ratio: Provides excellent structural integrity without being heavy.

- Exceptional Corrosion Resistance: Highly resistant to rust, chemicals, and saltwater, making it ideal for items used in demanding environments or frequently exposed to moisture or skin oils.

- Non-Magnetic: A key property inherited from titanium, important for specific technical or personal uses.

- Biocompatibility: Safe for prolonged contact with skin, making it suitable for jewelry and everyday carry items.

- Exceptional Aesthetic Potential: Unique layered patterns combined with the ability to create vibrant, multicolored surfaces via controlled oxidation. Each board and finished piece has a unique pattern.

- Durability: Resistant to corrosion and wear, ensuring the material maintains its appearance and integrity over time.

Different Forms of Titanium Damascus Boards

Titanium Damascus is available in various flat forms, often broadly referred to as “boards”:

- Multi-Layer Billets: These are typically thicker, less finished blocks of Timascus, representing a raw material state. They are ideal for projects requiring significant machining or where a very deep or complex pattern is desired.

- Patterned Sheet / Plate: Thinner, more finished flat sections. These are often preferred for applications requiring less extensive machining, such as inlays, decorative panels, watch components, or lighter frames. Variations like MokuTiZr, which combine titanium with zirconium, offer even more complex patterns and unique color responses.

- Flat Bars: Striking a balance between billets and thin sheets, flat bars provide a versatile rectangular cross-section suitable for various machined components.

The choice between these forms depends on the specific application, the required thickness, the complexity of the final shape, and the desired pattern density.

Applications for Titanium Damascus Boards

Timascus Boards are used as the raw material for creating high-end, custom, and artistic items through machining, cutting, and shaping:

- Custom Knives & Accessories: A primary use is machining into knife scales (handles), bolsters, pocket clips, and decorative inlays. (Note: Timascus is not suitable for knife blades as it does not harden sufficiently to hold a cutting edge).

- Jewelry & Luxury Goods: Machined into components for unique rings, pendants, bracelets, watch cases, pen bodies, lighter cases, cufflinks, and other high-value accessories.

- Collectibles & Art Objects: Used to create decorative panels, components for sculptures, or custom display pieces.

- High-End Kitchen Tools: While not typically used for functional surfaces like cutting boards, Timascus can be used for decorative handles or inlays on premium kitchen tools, leveraging its aesthetics and corrosion resistance.

- Specialty Hardware: Machined into custom fasteners, plates, or components for applications where lightweight, non-magnetic, corrosion-resistant hardware with aesthetic appeal is desired.

Distinguishing Timascus Boards from Pure Titanium Cutting Boards

It’s important to distinguish between Titanium Damascus Boards and Pure Titanium Cutting Boards. Pure titanium cutting boards are available and offer functional benefits like antibacterial properties, durability, lightweight design, and hygiene for kitchen use. However, they are made from a single type of titanium and lack the layered structure and the ability to display the vibrant, multicolored patterns characteristic of Damascus titanium. Pure titanium boards are functional kitchenware; Timascus boards are premium materials for crafting and decorative applications.

Working with Timascus Boards

Machining Timascus boards requires expertise in working with titanium alloys, including using sharp carbide tooling and appropriate machining speeds to manage heat and wear. Surface finishing (polishing, blasting) reveals the pattern, and controlled oxidation (heat coloring or anodizing) is applied after shaping to bring out the vibrant colors on the finished part.

Maintenance involves protecting the oxide color layer by avoiding harsh abrasives or chemicals. Simple cleaning with mild soap and water is usually sufficient. While generally stable, minimizing prolonged exposure to strong UV light is sometimes recommended.

Partnering with a Supplier

Sourcing authentic, high-quality Titanium Damascus Boards (billets, sheets, plates) with consistent layering, alloy composition, and pattern potential is crucial. This requires partnering with reputable suppliers who specialize in this complex material. Look for suppliers with demonstrated expertise in titanium metallurgy, the Timascus manufacturing process (diffusion welding, forging, coloring), and quality control.

A supplier with a strong background in various titanium products, like Ti Time Company specializing in titanium and titanium oxide products, possesses the fundamental knowledge of titanium alloys (such as CP Ti and Ti-6Al-4V) that are the building blocks of Timascus. While they may not directly produce Timascus boards, their expertise is relevant to understanding material quality and potentially sourcing high-quality raw alloys for Timascus manufacturers, serving the high-end market seeking premium titanium materials.

Titanium Damascus Boards (Timascus Sheets/Plates) are unique, high-performance materials that stunningly combine the durability and lightweight nature of titanium alloys with intricate, multi-colored layered patterns. Supplied in flat forms for machining, they are a premier choice for creating visually exceptional and lasting components in custom knives, jewelry, luxury goods, and art objects. While representing a significant investment and requiring specialized craftsmanship to work with, the unparalleled blend of aesthetic appeal and titanium’s superior properties makes Timascus boards a highly sought-after material in the world of custom fabrication and collectibles.

FAQs About Titanium Damascus Board

What are the main differences between titanium Damascus plates and billets?

Billets are generally thicker, less finished blocks of Titanium Damascus, typically used as raw material for heavy machining. Plates (or sheets) are thinner, more finished flat sections, often preferred for applications requiring less machining or intricate inlays. The term “board” can sometimes refer to either form.

How durable are titanium Damascus cutting boards for everyday kitchen use?

Titanium Damascus is generally not used for functional cutting board surfaces. While titanium itself is durable and antibacterial (as in pure titanium cutting boards), Timascus is a premium material valued for its aesthetics and is used for decorative handles or inlays on high-end kitchen tools, not the cutting surface itself. Pure titanium cutting boards (non-Damascus) are durable for kitchen use.

Are there unique patterns or designs available in titanium Damascus sheets?

Yes, Titanium Damascus sheets (and billets/plates) come in various unique patterns depending on how the layered billet was forged and manipulated (e.g., twist, random, mosaic). The specific pattern and the chosen coloring method (heat vs. anodizing) contribute to the material’s individuality. Variations combining titanium with other metals like zirconium (e.g., MokuTiZr) also offer distinct patterns and color responses.

What advantages do titanium Damascus materials offer over traditional steel?

Titanium Damascus is significantly lighter weight, non-magnetic, and offers superior corrosion resistance (it will not rust) compared to traditional steel. It also provides vibrant, multicolored aesthetics through oxidation, unlike steel’s typically monochrome patterns revealed by etching.

Where can I find high-quality titanium Damascus products for culinary or craft purposes?

High-quality Titanium Damascus material (billets, sheets, rods) can be found from specialized metal suppliers or custom material vendors known for exotic alloys. Finished Timascus products (like knife handles or jewelry) are typically found from custom knife makers, independent jewelers, or high-end craft artisans who specialize in working with this material. Pure titanium cutting boards (non-Damascus) are available from various kitchenware suppliers.