What is Timascus Knife Handle Material?

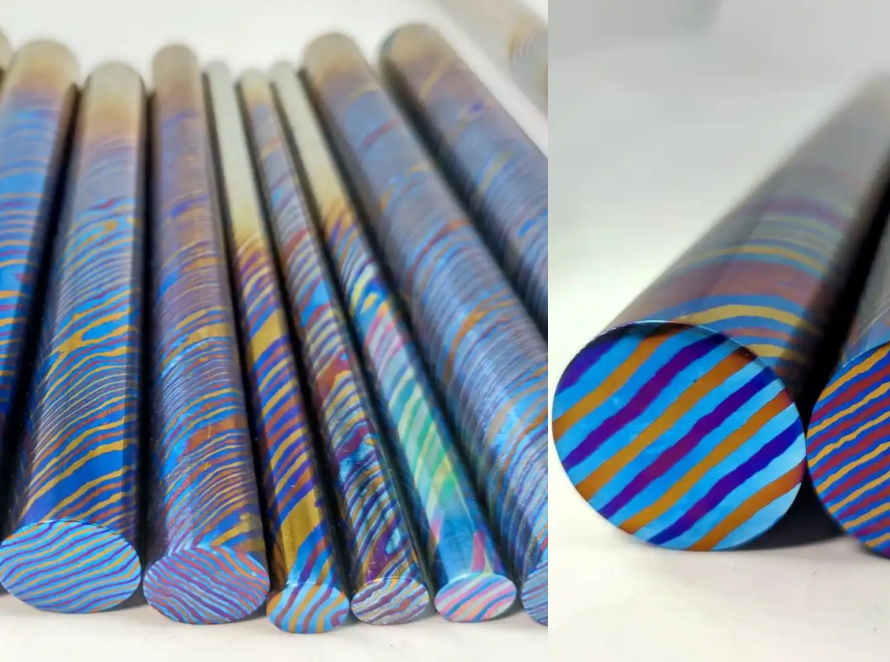

Timascus, a portmanteau of ‘Titanium Damascus,’ is an advanced composite material crafted by meticulously layering and diffusion welding different grades of titanium alloys. Typically, it comprises 50 to 300 layers of commercially pure titanium (CP Titanium) and the stronger Ti-6Al-4V alloy. These specific alloys are chosen for their distinct responses to heat and surface treatments. This intricate laminated structure, when subjected to subsequent processing like forging, grinding, and controlled oxidation, forms unique titanium oxide layers of varying thickness and color on its surface, revealing the material’s signature vibrant, multicolored patterns.

Key Advantages for Knife Handles

Timascus offers a suite of compelling advantages that make it a superior choice for premium knife handles:

- Remarkably Lightweight: One of Timascus’s most significant advantages for knife handles is its remarkable lightness. Titanium’s density is approximately 4.5 g/cm3, making it about 45% lighter than steel. This reduction in handle weight enhances the overall balance, carrying comfort, and usability of the knife, especially for Everyday Carry (EDC) applications.

- Exceptional Corrosion Resistance: Unlike many traditional knife handle materials, Timascus boasts extreme resistance to rust and corrosion. Its inherent properties make it impervious to moisture, sweat, and various environmental elements, simplifying maintenance and ensuring long-term durability without concerns about oxidation.

- High Strength & Durability: Despite its lightweight nature, titanium alloys are inherently strong and durable. Timascus provides a robust and resilient handle material that can withstand demanding environments and regular use without compromising structural integrity.

- Non-Magnetic: For specialized applications where magnetic interference is a concern, Timascus offers a non-magnetic solution, a characteristic unique to titanium-based materials.

- Stunning Aesthetics: The visual appeal of Timascus is arguably its most celebrated feature. Through precise anodizing or controlled heat treatment (flame coloring), Timascus knife handles display a rich tapestry of vibrant, swirling colors—blues, purples, golds, greens, and more—making each handle a distinct piece of art with strong visual impact. This optical effect is due to light interference caused by varying thicknesses of transparent titanium oxide layers on the different alloys.

Crafting with Timascus: Processing & Application

Timascus is predominantly utilized in the creation of high-end custom knife handles and decorative accents, such as pivot collars, thumb studs, and pocket clips. Its allure stems from its ability to significantly elevate both the artistic value and the practical performance of a knife.

However, working with Timascus is demanding due to its high material cost and inherent processing difficulty. The complex multi-step manufacturing of the material itself (forge welding, patterning), coupled with the need for specialized tooling (e.g., carbide cutters) and techniques during subsequent shaping and finishing, often leads to increased material waste and a higher overall cost for the finished product. Achieving the full aesthetic potential of Timascus requires professional finishing techniques, including careful polishing or blasting followed by precise heat treatment or anodization to bring out the desired colors.

Market Positioning and Sourcing

Timascus knife handles are a hallmark of limited edition and bespoke custom knives, occupying an ultra-high-end segment of the market. Its unique properties and aesthetic appeal have led many renowned knife brands (e.g., ZT (Zero Tolerance), Chris Reeve Knives (CRK), CKF (Custom Knife Factory)) to incorporate titanium alloys and Timascus into their premium offerings.

For individual knife makers and enthusiasts, raw Timascus material is available in various forms, including plates (sheets) and round rods, from specialized suppliers for custom handle fabrication.

Timascus Knife Handle Material: Pros & Cons Summary

| Pros () | Cons () |

|---|---|

| Lightweight, reduces overall knife weight | High material price, very expensive |

| Excellent corrosion resistance (no rust) | Difficult to process, high material waste |

| High strength, very durable | Surface color is an anodized layer, may fade over time/heavy use |

| Unique colorful visual effects | Requires professional equipment and expertise for processing and coloring |

| Non-magnetic, suitable for special uses |

As a knife handle material, Timascus masterfully combines the lightweight strength of titanium alloys with the unique, captivating beauty of layered Damascus patterns. It stands as an ideal choice for high-end knife manufacturing, not only enhancing the functional performance of the blade but also profoundly elevating its visual and artistic value. For knife enthusiasts and collectors who prioritize individuality, exceptional quality, and striking aesthetics, Timascus knife handles offer an unparalleled experience.

Partnering with a Supplier

For those seeking to source high-quality Timascus knife handle material, partnering with a knowledgeable supplier is paramount. Reputable suppliers ensure the material’s authenticity, consistent layering, and proper alloy composition. Companies like Ti Time Company, specializing in various titanium products, including titanium alloys and titanium oxide, possess deep expertise in the raw materials foundational to Timascus. While they may not directly produce finished Timascus handles, their understanding of titanium metallurgy is invaluable for sourcing quality base materials or for general consultation on premium titanium applications.