The Core Principle of Timascus Heat Treatment Coloring: The Magic of Light

The secret behind Timascus heat treatment coloring lies in the extremely thin, transparent titanium oxide (TiO₂) film that forms on the surface of the titanium alloy during high-temperature oxidation. This film isn’t a pigment; it creates color through the phenomenon of light interference.

- Interference Effect of Titanium Oxide Film: When light hits the titanium oxide film, part of it reflects off the film’s surface, while another part penetrates the film and reflects off the underlying titanium alloy surface. These two reflected light rays then interfere with each other. When the peaks or troughs of the two light waves superimpose, they enhance certain wavelengths of light, which are then perceived by the human eye as specific colors. Conversely, when a peak and a trough cancel each other out, that wavelength of light is diminished.

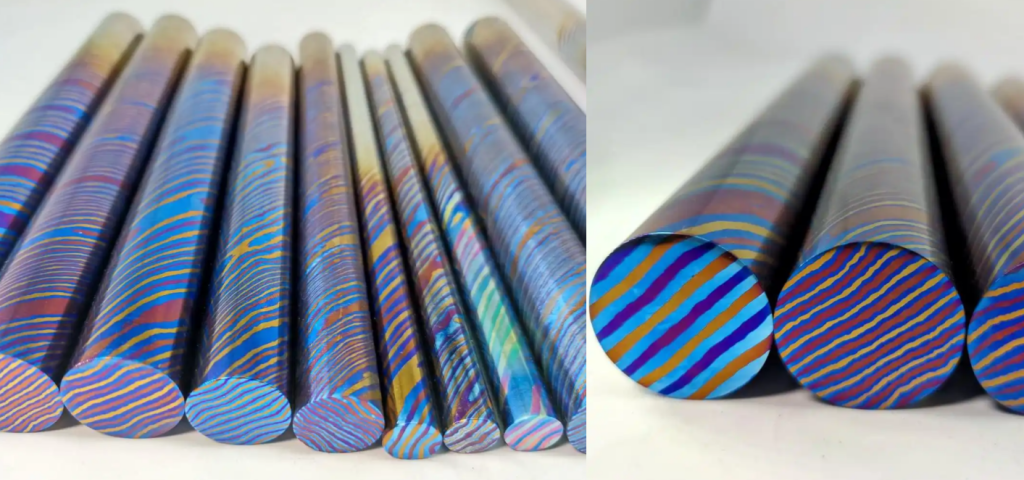

- Color and Film Thickness Correlation: The thickness of the titanium oxide film is the key determinant of color. As the oxide film thickens, the optical path difference changes, causing different wavelengths of light to be enhanced or diminished, resulting in various colors. Typically, the color progression is: gold → blue → purple → green → red.

- Crucial Control of Temperature and Time: The thickness of the oxide film is directly controlled by the precise management of heat treatment temperature and time. Higher temperatures and longer durations accelerate the growth of the oxide film, leading to a thicker final film. Generally, the coloring temperature ranges from 400℃ to 700℃, with durations varying from a few minutes to several tens of minutes. This demands extensive experience and precise control over process parameters from the operator.

Timascus Heat Treatment Coloring Process Steps: The Art of Precision

Achieving the ideal Timascus heat treatment coloring effect requires a rigorous process.

Surface Pre-treatment: The Foundation Thoroughly cleaning the Timascus surface before heat treatment coloring is fundamental to success. Any grease, oxides, fingerprints, or impurities can lead to uneven oxide film formation, color variations, or even prevent coloring altogether.

- Cleaning Methods: Typically, ultrasonic cleaning with specialized cleaning agents or chemical cleaning (such as pickling) is used. After cleaning, it’s crucial to rinse thoroughly with pure water and dry quickly to avoid water stain residue.

Heat Treatment Heating: The Art of Temperature and Time Place the pre-treated Timascus material into an atmosphere-controlled furnace. The furnace atmosphere is usually air, but it can also be an inert gas environment for more uniform or specific effects.

- Heating and Holding: Gradually raise the temperature to the target temperature (around 450℃-700℃) and maintain it for a specific duration. This holding period is crucial for the uniform growth of the oxide film.

- Temperature and Time Decisions: Experienced operators will precisely set the temperature and holding time based on the desired color, the specific grade of Timascus, and the equipment characteristics. For example, lower temperatures and shorter times might produce gold or blue, while higher temperatures and longer times can yield purple, green, or even red.

Cooling and Color Setting: Stability and Protection After the holding period, turn off the heating and allow the Timascus material to cool slowly to room temperature in a controlled atmosphere.

- Importance of Slow Cooling: Slow cooling helps stabilize the oxide film, preventing it from cracking or peeling due to rapid temperature changes.

- Atmosphere Control: The atmosphere during cooling should also remain clean to avoid re-attachment of impurities.

Post-treatment: The Finishing Touch While heat-treated Timascus is already aesthetically pleasing, post-treatment can further enhance its luster and durability.

- Light Polishing: This can remove any fine dust from the surface, improving the transparency and luster of the colors.

- Sealing Treatment (Optional): For specific applications, a transparent protective coating can be considered to further enhance abrasion resistance and corrosion resistance, extending the vibrancy of the colors.

- Selective Coloring and Pattern Design: Through masking or localized heating, it’s possible to achieve selective coloring on Timascus, creating unique patterns and textures. This requires extremely high precision and design capabilities.

Characteristics and Advantages of Timascus Heat Treatment Coloring: Value Beyond Color

Heat treatment coloring not only bestows aesthetic beauty upon Timascus but also brings a series of performance enhancements, which is why it’s highly regarded.

- Rich and Stable Colors: By precisely adjusting process parameters, a wide range of gradient colors can be achieved, from golden yellow, blue-purple, green, to red. Because the color is a physical property of the oxide film rather than a chemical dye, the colors are long-lasting and fade-resistant, maintaining their vibrancy even after prolonged use.

- No Chemical Dyes, Environmentally Safe: Heat treatment coloring is a purely physical oxidation process that requires no chemical dyes or toxic coatings. This is not only environmentally friendly but also makes the product safer for skin contact, aligning with modern demands for green practices and human health.

- Enhanced Corrosion Resistance: The titanium oxide film itself possesses excellent corrosion resistance. Forming this dense oxide film on the surface of the titanium alloy creates a robust protective barrier, significantly improving Timascus’s resistance to oxidation and corrosion in various environments.

- Increased Surface Hardness and Wear Resistance: The hardness of the titanium oxide layer is generally higher than that of the underlying titanium alloy. Therefore, the heat treatment coloring process can also, to some extent, increase the surface hardness of Timascus, thereby enhancing its wear resistance and extending product lifespan.

- Suitable for Complex Shapes and Detailed Decoration: The heat treatment coloring process doesn’t rely on complex molds, allowing for coloring of any shape of Timascus component. It can even achieve localized coloring or intricate pattern customization, greatly expanding design freedom.

Wide Application Areas of Timascus Heat Treatment Coloring

Due to its unique visual effects and performance advantages, heat-treated Timascus is widely used in several high-end fields:

- High-End Custom Knife Handles: Adds a unique artistic touch and personalized identification to knives, while also providing additional corrosion protection.

- Jewelry: As a unique metal material, it brings rich colors and textures to necklaces, bracelets, rings, and other jewelry.

- Watch Components and Precision Instrument Casings: Enhances the texture and visual appeal of products, signifying a high-end positioning.

- Artworks and Handicrafts: Provides artists and designers with a new creative medium to realize their unique artistic concepts.

- Eyeglass Frames: Lightweight, durable, and available in various colors, aligning with fashion trends.

Expert Advice and Precautions

While Timascus heat treatment coloring offers significant advantages, its specialized nature demands that operators adhere to the following precautions to ensure optimal results and product quality:

- Precise Control of Temperature and Time: This is the core to achieving the desired color. Any slight fluctuation can lead to color variations. It is recommended to use high-precision temperature control equipment and establish a comprehensive database of process parameters based on experimental data.

- Thorough Surface Pre-treatment: Any residue can lead to uneven coloring or spotting. Ensure the surface is impeccably clean.

- Oxide Film Thickness and Performance: If the heat treatment temperature is too high or the time is too long, the oxide film may become excessively thick, potentially dulling the color or causing the oxide film to crack, affecting aesthetics and durability. Therefore, balancing aesthetics with performance is crucial.

- Professional Equipment and Experience: Timascus heat treatment coloring requires specialized heating furnaces, temperature control equipment, and atmosphere control systems. Additionally, the operator’s experience and professional knowledge are key to success. It is advisable to collaborate with professional titanium alloy processing manufacturers.

Conclusion: The Perfect Fusion of Color and Performance

Timascus heat treatment coloring is an advanced process that integrates artistry and functionality. By precisely controlling the thickness of the titanium oxide film on the surface of the titanium alloy, it bestows dazzling visual effects upon Timascus while significantly enhancing the material’s corrosion resistance and surface hardness. From high-end custom knives to jewelry, this technology continues to expand the application boundaries of Timascus, meeting the growing market demand for personalized, high-performance products.

If you require further information on specific process parameters, equipment recommendations, or custom production, Ti Time Company, as a professional manufacturer of titanium and titanium oxide electrodes, possesses extensive experience and specialized knowledge. Feel free to contact us, and we will be dedicated to providing you with solutions.

FAQs

What is the principle behind Timascus heat treatment coloring?

The principle of Timascus heat treatment coloring is based on the interference of light. During high-temperature oxidation, an extremely thin, transparent titanium oxide (TiO₂) film forms on the surface of the titanium alloy. When light strikes this film, part of it reflects off the film’s surface, and another part passes through the film and reflects off the titanium substrate. These two reflected light rays interfere with each other, and because the oxide film thickness varies, specific wavelengths of light are either enhanced or diminished, causing the human eye to perceive different colors. The film thickness determines the final color.

Which heat treatment method can enhance the color effect of Timascus?

The key to enhancing the color effect of Timascus lies in precisely controlling the temperature and time of the heat treatment. The most common method is air oxidation heat treatment. By precisely holding the material at specific temperatures (typically between 400℃-700℃), the growth rate and final thickness of the oxide film can be controlled to achieve the desired color. Some manufacturers may also experiment with slight oxidation in an inert gas atmosphere to achieve more uniform or unique color effects, but air oxidation remains the mainstream and stable method.

How is temperature controlled during heat treatment to achieve ideal color layers?

Controlling temperature for ideal color layers is a combination of experience and technique.

- Set Target Temperature: Choose the corresponding temperature range based on the desired color. For example, lower temperatures (e.g., 450℃-500℃) may produce gold or blue, while higher temperatures (e.g., 600℃-700℃) can yield green or red.

- Precise Temperature Control Equipment: Use a high-precision temperature-controlled heat treatment furnace to ensure uniform and stable temperature within the furnace, avoiding localized overheating or underheating.

- Experimentation and Record-Keeping: The oxidation characteristics of different Timascus grades and batches may vary slightly. It’s recommended to conduct small-batch trials, precisely record the color effects achieved with different temperature and time combinations, and build your own process parameter database.

- Multi-stage Heating (Optional): For situations requiring specific gradient effects, you can try multi-stage heating or multi-stage holding, though this increases operational difficulty.

Does Timascus require special protection after coloring to maintain long-lasting color?

After coloring, the oxide film on Timascus itself has good stability and corrosion resistance, and the colors are generally long-lasting and fade-resistant. However, to further maintain color vibrancy and prevent surface wear, consider the following:

- Avoid Strong Friction or Scratches: Although the oxide film has a certain hardness, severe friction or sharp objects can still damage the oxide layer, leading to color degradation.

- Avoid Contact with Strong Acids and Bases: Despite enhanced corrosion resistance, prolonged immersion or contact with high concentrations of strong acids and bases can still affect the oxide film.

- Light Polishing and Cleaning: Regularly wipe with a soft cloth to maintain its luster. For applications requiring higher protection, a transparent ceramic coating or nano-coating can be applied to the surface to increase wear and corrosion resistance, though this will slightly alter the original metallic texture.

How does this process affect the performance of the titanium alloy material?

The Timascus heat treatment coloring process generally has a positive impact on the overall performance of the titanium alloy material and does not cause negative effects (unless improperly executed).

- Positive Impacts:

- Enhanced Corrosion Resistance: The dense titanium oxide film formed on the surface has excellent chemical stability, significantly improving the material’s resistance to oxidation and corrosion.

- Increased Surface Hardness: The hardness of the titanium oxide layer is higher than that of the underlying titanium alloy, which can, to a certain extent, improve the material’s surface wear resistance.

- Biocompatibility (Relevant): Titanium oxide itself has good biocompatibility, making colored Timascus safer for applications involving skin contact, such as jewelry.

- Potential Negative Impacts (Usually due to improper operation):

- Slight Decrease in Ductility (Negligible): High-temperature treatment can cause titanium alloy grain growth, which theoretically might slightly affect the material’s ductility. However, within the normal coloring temperature and time ranges, this effect is usually very small and negligible for most applications.

- Brittle Oxide Layer: If the heat treatment temperature is too high or the time is too long, the oxide film can become excessively thick, potentially becoming brittle and prone to cracking or peeling, affecting both aesthetics and protective qualities. Therefore, precise control of process parameters is crucial.