What is Timascus? A Multi-Alloy Composite Masterpiece

The foundation of Timascus lies in its sophisticated composition and manufacturing process:

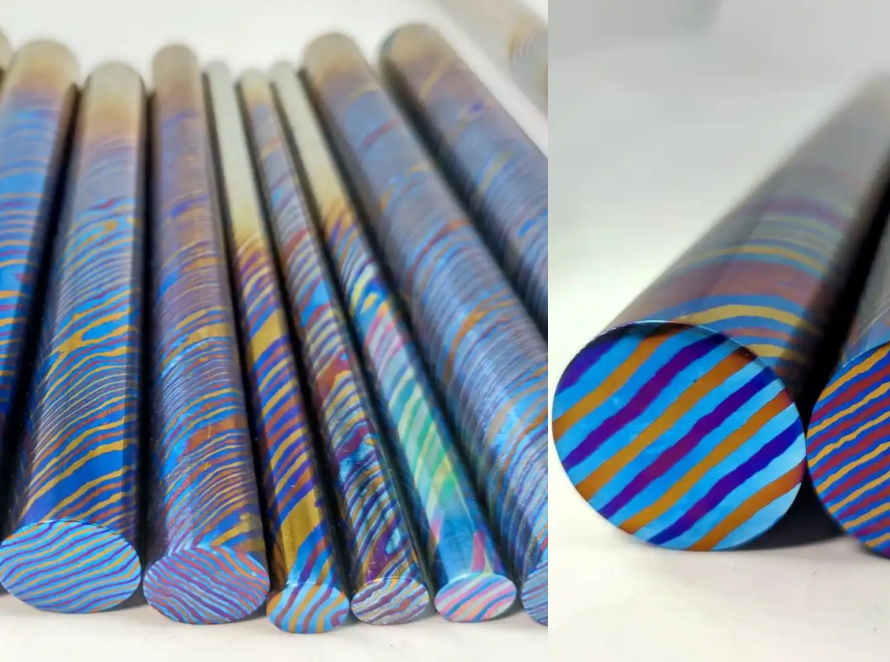

- Precision Multi-Alloy Layering: The core of Timascus involves the careful selection and layering of two or more distinct titanium alloys. Commonly, Commercially Pure (CP) Titanium (e.g., Grade 2, known for its excellent corrosion resistance and ductility) is alternated with Ti-6Al-4V (Grade 5), a much stronger and more robust aerospace-grade alloy. These layers, typically ranging from 50 to 300 in number, are stacked with meticulous precision. Variations in the thickness and sequential arrangement of these different alloys are intentionally designed to create the unique patterns and contribute to the final color effects seen in Timascus.

- Seamless Diffusion Welding: The stacked multi-alloy layers undergo a critical process called diffusion welding. This involves heating the layers to extremely high temperatures, approximately 1200∘C, under significant pressure. Crucially, this process is conducted within a sealed steel container filled with an argon inert atmosphere to prevent any oxidation of the reactive titanium. At these elevated temperatures, atoms from adjacent layers intermingle and fuse, creating a perfectly bonded, seamless composite material without melting.

- Artistic Forging & Vibrant Coloring: Following diffusion welding, the solid Timascus billet is subjected to forging (and often rolling). This mechanical deformation shapes the material into its desired form (e.g., rods, sheets) and, more importantly, stretches and distorts the internal layers, bringing the unique patterns to the surface. The final, captivating colors are then achieved through heat treatment or anodization. These processes form thin titanium oxide films of varying thicknesses on the different alloy layers, resulting in the brilliant, iridescent spectrum of colors through light interference.

Unrivaled Characteristics & Mechanical Advantages

Timascus distinguishes itself through a powerful combination of inherent titanium properties and the benefits of its composite structure:

- High Strength & Lightweight: Leveraging titanium’s exceptional strength-to-weight ratio, Timascus offers superior mechanical performance. With a density of only about 4.5 g/cm3 (approximately 60% that of steel), it provides robust durability and excellent tensile strength (often between 800−1100 MPa), making it ideal for applications requiring both lightness and immense resilience.

- Exceptional Corrosion Resistance & Non-Magnetic: Inheriting titanium’s renowned chemical inertness, Timascus exhibits outstanding resistance to corrosion from saltwater, acids, and other harsh environmental elements. Furthermore, being non-ferromagnetic, it is completely non-magnetic, a crucial attribute for sensitive instruments and specialized environments.

- Unique Aesthetic Patterns & Customization: Perhaps its most striking feature is its aesthetic versatility. The multi-alloy layering, combined with the post-forging patterns and heat treatment coloring, results in dynamic, one-of-a-kind patterns and a rich palette of iridescent colors. The ability to vary alloy combinations, layer counts, thicknesses, and heat treatment parameters offers vast possibilities for personalized customization.

- Balanced Mechanical Performance: The composite nature of Timascus provides a superb balance of strength and toughness, reducing the risk of brittle fracture common in some high-strength materials. It also boasts a high fatigue life, making it suitable for dynamic load environments. Despite titanium’s general hardness, Timascus, with appropriate techniques, exhibits good machinability for precise shaping and finishing. Additionally, titanium alloys can maintain their mechanical properties at relatively higher temperatures, adding to Timascus’s versatility.

Typical Mechanical Properties of Timascus

While specific properties can vary based on the exact alloy proportions, forging techniques, and final heat treatment, the general mechanical performance of Timascus is consistently impressive:

| Performance Metric | Typical Value | Description |

|---|---|---|

| Density | 4.4−4.5 g/cm3 | Approximately 60% the weight of steel |

| Tensile Strength | 800−1100 MPa | High ultimate strength, resistance to breaking under tension |

| Yield Strength | 700−950 MPa | High resistance to permanent deformation under stress |

| Elongation (Ductility) | 10%−15% | Good plasticity and toughness, less prone to brittle fracture |

| Hardness (Vickers) | 320−400 HV | Moderate hardness for wear resistance and machinability |

| Elastic Modulus | 110−120 GPa | Good elasticity and stiffness |

| Corrosion Resistance | Excellent | Outstanding resistance to oxidation, salt spray, acids, alkalis |

Diverse Applications of Timascus Multi-Alloy Composite

The unique blend of superior mechanical properties and stunning aesthetics makes Timascus highly sought after across various high-end sectors:

- High-End Custom Knife Handles: Prized for its lightweight nature, strength, durability, and visually captivating patterns, significantly enhancing both the performance and collectible value of custom knives.

- Luxury Jewelry & Decorative Items: Its artistic patterns, vibrant colors, and inherent resistance to tarnish make it an ideal material for unique rings, pendants, watch components, and other premium accessories.

- Art & Craft Pieces: Used by artisans to create unique sculptures and decorative objects where material innovation meets artistic expression.

- Precision Mechanical & Electronic Components: For specialized applications in aerospace, medical devices, and high-performance electronics, where lightweight, strength, non-magnetic properties, and corrosion resistance are critical.

The Timascus multi-alloy composite represents a significant leap in material science, ingeniously combining the inherent high strength and lightweight characteristics of titanium alloys with the timeless artistry of layered patterns. Its complex manufacturing process, from multi-alloy stacking and diffusion welding to precision forging and vibrant coloring, ensures that each piece is a unique testament to innovation and craftsmanship. As a fusion of exceptional functionality and distinctive beauty, Timascus continues to push the boundaries of what is possible in premium design and engineering.

Partnering with a Supplier

For manufacturers and artisans seeking to integrate Timascus into their creations, securing high-quality material is paramount. Understanding the intricate metallurgical processes behind this composite is essential. Companies like Ti Time Company, specializing in titanium and titanium oxide electrode production, possess the foundational expertise in titanium alloys that is crucial for understanding the raw materials and processes that contribute to the quality and characteristics of Timascus. Their deep knowledge base can be invaluable for professionals seeking reliable sources and technical insights related to titanium and its advanced applications.

FAQs About Timascus: High Strength and Lightweight Material

How does Timascus's multi-alloy layering technique achieve rich color variations?

Timascus achieves rich color variations because it’s composed of different titanium alloys (e.g., CP Titanium and Ti-6Al-4V). When subjected to heat treatment or anodization, each alloy reacts slightly differently, forming titanium oxide (TiO2) films of varying thicknesses. These differing oxide thicknesses interact with light through interference, causing adjacent layers to display distinct and vibrant colors simultaneously, creating the rich, multi-hued patterns.

Why is Timascus so popular and valued in high-end knives?

Timascus is highly valued in high-end knives due to its unique combination of lightweight properties, exceptional strength, superior corrosion resistance, non-magnetic nature, and stunning aesthetic appeal. It provides a comfortable, durable, and visually distinctive handle material that significantly elevates the knife’s overall performance and collectible value.

How do different titanium alloy combinations affect Timascus's appearance and performance?

Different titanium alloy combinations (e.g., alternating CP Titanium and Ti-6Al-4V) primarily affect Timascus’s color contrast and overall mechanical strength. Alloys with differing oxide growth rates or optical properties will yield more distinct color separation after heat treatment. Stronger alloys like Ti-6Al-4V contribute to higher overall tensile and yield strength, while CP Titanium offers enhanced ductility and a distinct color response, creating varied visual textures.

How does the Timascus manufacturing process ensure each piece is unique?

The uniqueness of each Timascus piece stems from several factors: the randomness inherent in the forging process as layers distort and flow; the specific stacking sequence and thicknesses of the multi-alloy layers chosen by the artisan; and the variations in heat treatment or anodization that produce unique color patterns. The manual and artistic aspects of the process ensure that no two finished pieces will ever have exactly the same pattern or color distribution.

What specific advantages does Timascus offer in terms of mechanical performance?

Timascus offers several specific mechanical advantages: an excellent balance of high strength and good toughness (reducing brittleness); a high fatigue life suitable for dynamic loads; superior corrosion resistance against various environments (including salt water and many chemicals); and good machinability for precise shaping, making it a robust and versatile material for demanding applications.