Aerospace titanium is one of the most critical materials in modern aviation and space exploration. Known for its exceptional strength-to-weight ratio, heat resistance, and corrosion tolerance, titanium has revolutionized the aerospace industry by enabling safer, lighter, and more efficient aircraft and spacecraft.

At Ti Time Company, we specialize in the custom production and supply of premium-grade titanium alloys tailored specifically for aerospace applications, providing both raw materials and finished components trusted by engineering professionals worldwide.

1. Experience: A Proven Record in Aerospace Titanium Supply

With decades of experience in titanium manufacturing and alloy formulation, Ti Time Company has supplied aerospace OEMs, defense contractors, and space tech innovators with titanium materials that meet ASTM, ISO, and aerospace-grade standards.

Our deep understanding of material performance under flight conditions ensures that every product we deliver contributes to maximum reliability and performance.

2. Why Titanium is Essential in Aerospace Engineering

✦ Outstanding Strength-to-Weight Ratio

Titanium is 30% stronger than steel but nearly 50% lighter, improving aircraft fuel efficiency, speed, and maneuverability—especially critical for long-haul flights and space-bound missions.

✦ Heat and Fatigue Resistance

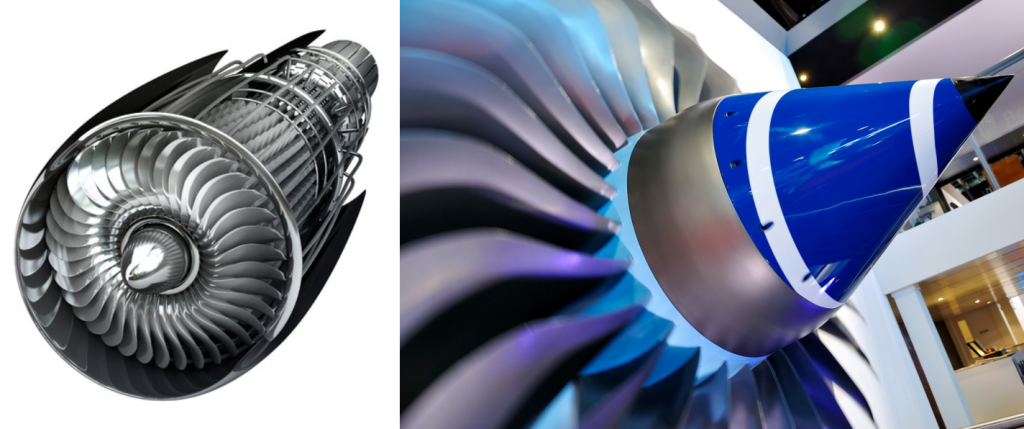

Titanium alloys can withstand temperatures up to 600°C (1112°F), making them ideal for engine parts like turbine blades, compressor discs, and exhaust systems.

✦ Superior Corrosion Resistance

Titanium resists oxidation and is chemically compatible with carbon fiber composites (CFRPs), preventing galvanic corrosion in modern airframe structures.

✦ Long-Term Durability

Titanium extends component lifespan by resisting fatigue and environmental degradation, reducing maintenance costs over an aircraft’s lifecycle.

3. Common Aerospace Titanium Alloys We Supply

| Alloy | Key Benefits |

|---|---|

| Ti-6Al-4V (Grade 5) | The most widely used aerospace titanium alloy; strong, weldable, corrosion-resistant |

| Ti-6Al-4V ELI | “Extra Low Interstitials”; ideal for fatigue-sensitive components in engines and landing gear |

| Ti-6242 / Ti-6246 | High-temperature titanium alloys for turbine engine components |

| Beta Alloys | High strength, deep hardenability; used in fasteners and landing gear |

4. Aerospace Applications of Titanium

Jet Engine Components: Turbine disks, compressor blades, casings

Airframe Structures: Fuselage frames, wing spars, fasteners

Landing Gear: Shock-resistant, lightweight structures

Spacecraft: Satellite frames, rocket nozzles, interplanetary mission components

5. Innovations in Aerospace Titanium Manufacturing

Modern manufacturing technologies such as laser wire additive manufacturing (LWAM), electron beam melting, and hot isostatic pressing are reducing cost and waste in titanium component production. These innovations make titanium more accessible for commercial aviation, space exploration, and defense.

6. Titanium Market Outlook

Global Aerospace Titanium Market (2023): ~$4.14 billion

Projected Growth by 2030: ~$7.04 billion

Growth Drivers: Lightweight aircraft design, demand for fuel efficiency, expansion of space missions

Major players in the aerospace titanium market include VSMPO-AVISMA, Timet, RTI International Metals, and Ti Time Company, which offers flexible production capacities, global shipping, and certified aerospace-grade materials.

FAQs – Aerospace Titanium from Ti Time Company

What is the most commonly used titanium alloy in aerospace?

Ti-6Al-4V (Grade 5) is the most widely used due to its balance of strength, corrosion resistance, and weldability.

Can titanium withstand high engine temperatures?

Yes. Many titanium alloys remain stable at up to 600°C, making them perfect for turbine blades and exhaust systems.

Why is titanium favored over aluminum or steel in aircraft?

Titanium is lighter than steel and stronger than aluminum, offering better fuel efficiency without compromising safety.

Does Ti Time Company offer aerospace certification for materials?

Absolutely. All aerospace titanium materials from Ti Time comply with ASTM B348, AMS 4911, and other aerospace-grade certifications.

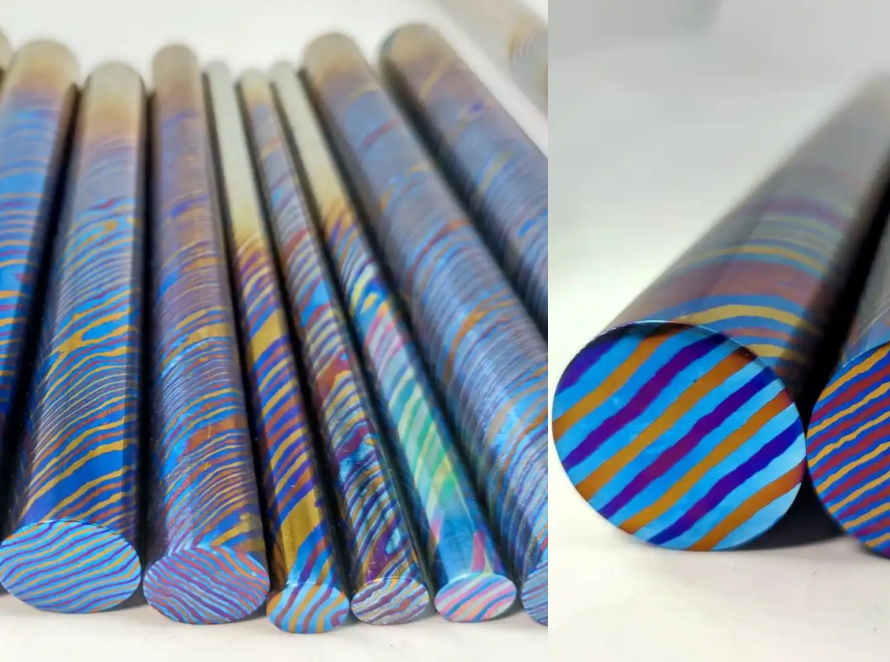

Can I request custom aerospace titanium alloys or shapes?

Yes. We provide custom billet, forged, machined, or rolled titanium products to match your exact aerospace application requirements.