What is a Titanium-Vanadium Alloy Electrode?

A Titanium-Vanadium Alloy Electrode is an innovative material composed primarily of titanium (Ti) and vanadium (V), often produced via electrodeposition from molten salt baths (e.g., LiCl-KCl mixtures). This alloy combines the mechanical strength, corrosion resistance, and electrochemical stability needed for critical industrial uses.

Key Features and Benefits

✅ Superior Corrosion Resistance

Especially effective in aggressive chloride or acidic environments, ideal for electrochemical reactors.

✅ Excellent Mechanical Strength

The fine-grained microstructure and β-phase dominance deliver high toughness and durability under stress.

✅ Electrocatalytic Activity

Enhanced surface area (often cauliflower-like or dendritic) offers excellent catalytic performance for electrochemical reactions.

✅ Controlled Alloy Composition

Adjustable Ti/V ratios allow fine-tuning of electrode performance for specific processes.

✅ Thermal and Structural Stability

Performs reliably at elevated temperatures with minimal phase change or deformation.

Applications of Titanium-Vanadium Alloy Electrodes

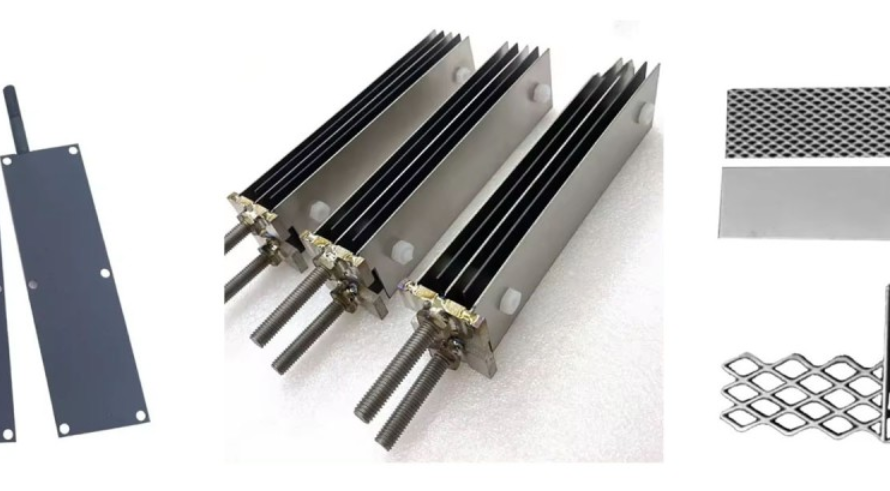

Electroplating and Electroforming: High-strength base material for decorative and functional coatings

Water Electrolysis and Wastewater Treatment: Resistant to scaling, corrosion, and fouling

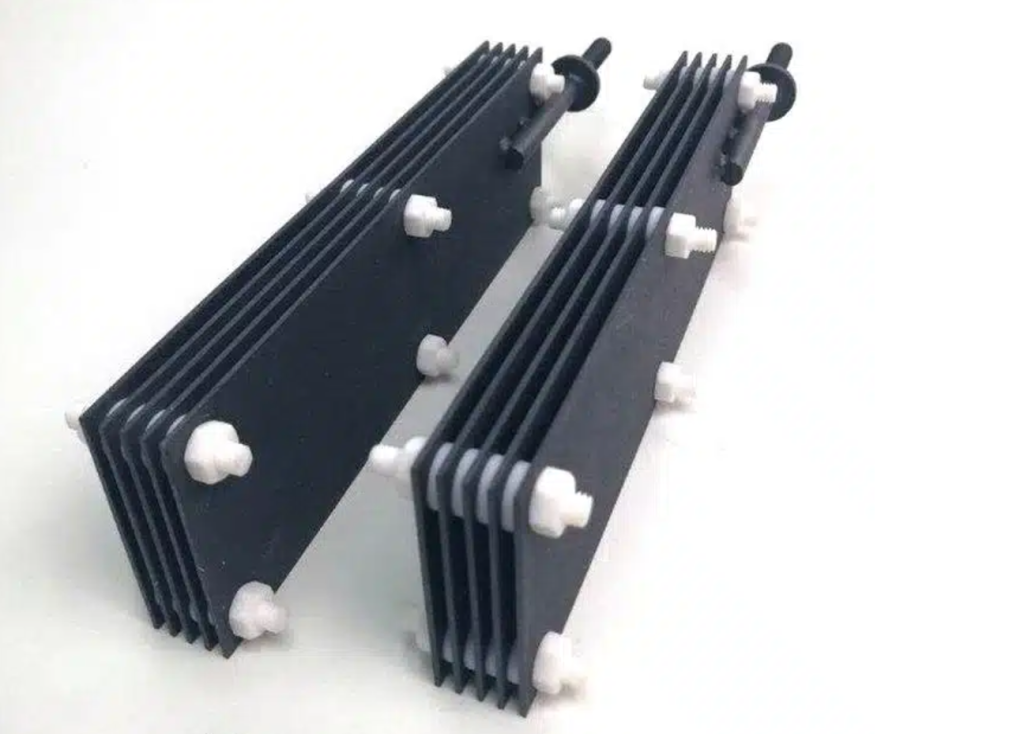

Hydrogen Production: Serves in anode or cathode roles for green hydrogen generation

Battery and Energy Storage: Promising as a current collector or catalytic surface in advanced battery systems

Industrial Electrolysis: Durable for long-term use in harsh industrial electrochemical cells

Advanced Manufacturing Process at Ti Time Company

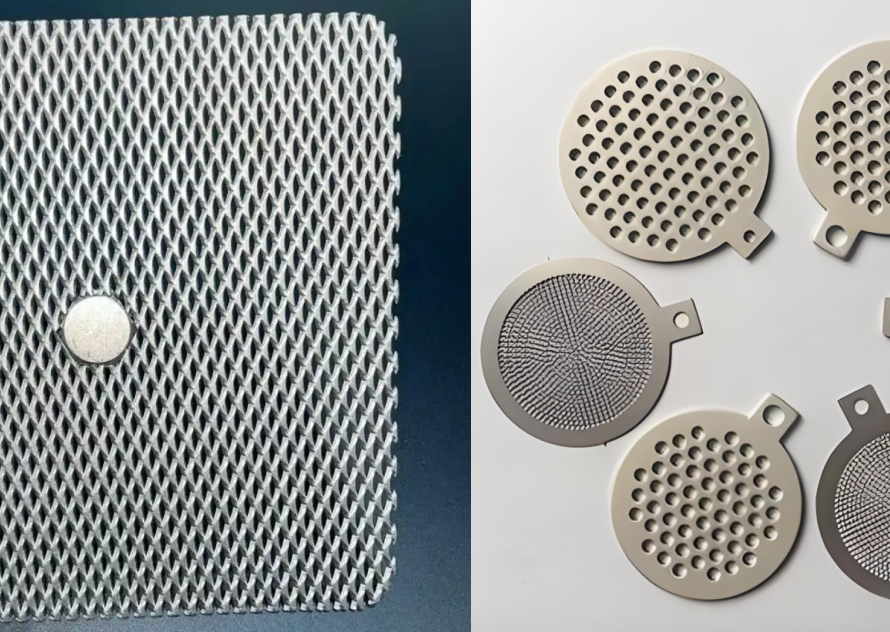

Titanium Substrate Processing – High-purity titanium is shaped and treated for uniform surface activation

Electrodeposition of Ti-V Alloy – Precise control of voltage, current, and molten salt chemistry ensures alloy quality

Microstructure Optimization – Post-treatment and thermal conditioning refine the β-phase and grain boundaries

Testing & Customization – Each electrode undergoes microstructural, corrosion, and conductivity testing before shipment

FAQs – Titanium-Vanadium Alloy Electrode

What advantages does vanadium bring to titanium alloy electrodes?

Vanadium enhances the β-phase stability, mechanical toughness, and electron transfer efficiency, especially for electrochemical applications.

Can Ti Time customize the Ti-V ratio based on my application?

Absolutely. We offer tailored Ti/V compositions and coatings depending on the required performance (e.g., corrosion resistance, conductivity).

Are these electrodes suitable for green hydrogen production?

Yes, our Ti-V electrodes are suitable for electrolyzers in water-splitting systems, especially under alkaline or acidic conditions.

What surface morphologies can be achieved?

We offer dendritic, cauliflower, or smooth finishes based on the desired surface area and catalytic function.

Do you provide R&D samples for pilot testing?

Yes, Ti Time provides lab-scale samples and works with industrial partners in joint development programs.