Why Titanium Electrodes for Electrolysis?

Titanium electrodes are highly valued in electrochemical applications due to the metal’s:

Outstanding corrosion resistance

Excellent conductivity when properly coated

Chemical inertness in harsh electrolytic environments

Mechanical strength and durability

To enhance performance, titanium substrates are often coated with Mixed Metal Oxides (MMO) like RuO₂, IrO₂, or Pt group metals. These coatings improve current efficiency, service life, and catalytic activity—making them ideal for long-term, high-load electrolysis processes.

Ti Time – Custom Electrolysis Titanium Electrode Manufacturing

Ti Time Company offers custom manufacturing of titanium electrodes tailored for:

Water electrolysis (H₂ & O₂ generation)

Chlor-alkali production (Cl₂, NaOH, H₂)

Electrochemical reduction of TiO₂ to metallic Ti

Electroplating & anodizing

Desalination and brine treatment

Product options include:

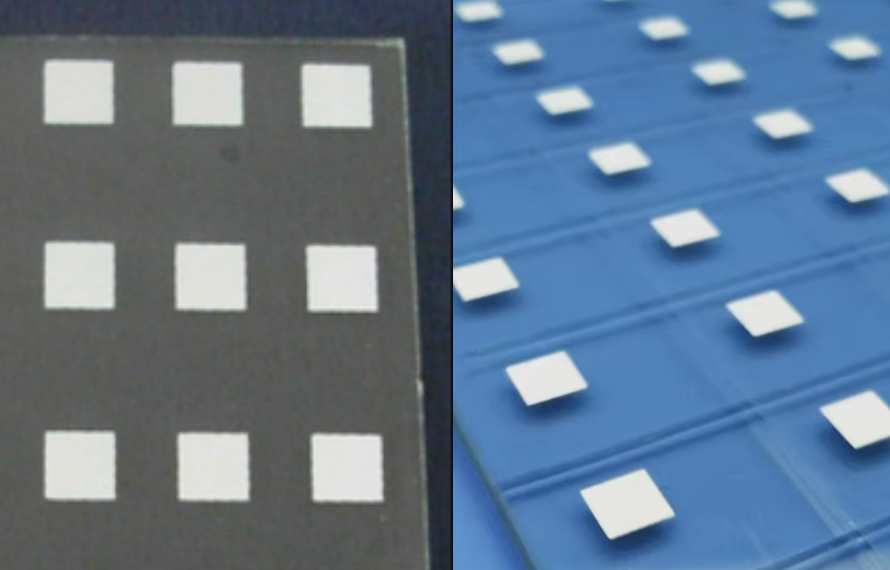

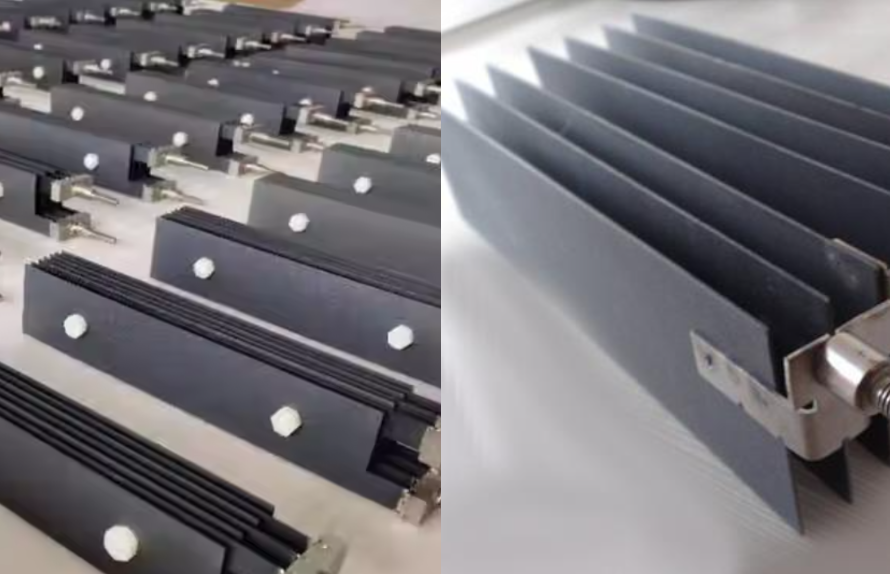

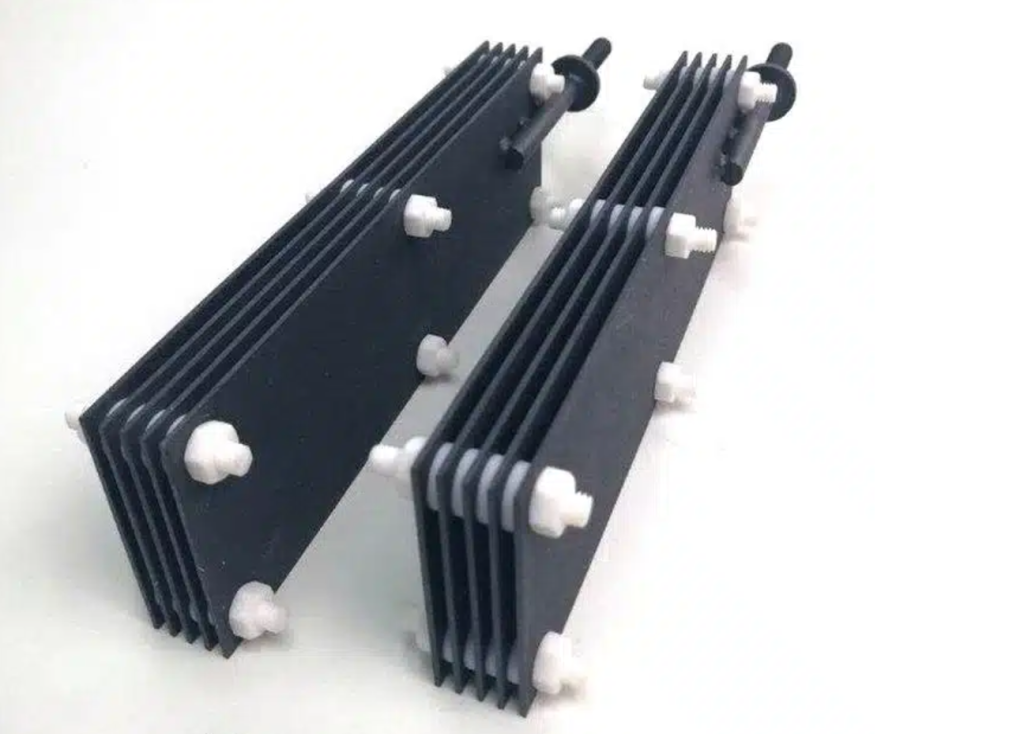

Titanium anodes (MMO, platinum-coated, or bare Ti)

Titanium cathodes

Mesh, sheet, rod, tube, or custom shapes

Electrodes for molten salt electrolysis (NaCl-CaCl₂ system)

Each electrode is engineered based on client requirements such as:

Electrolyte chemistry

Temperature & voltage range

Desired reaction (oxidation or reduction)

Electrode lifetime expectations

Geometry & mounting design

Applications of Titanium Electrodes in Electrolysis

Water Electrolysis (Hydrogen Production)

Titanium serves as a stable base for MMO coatings in both anode and cathode roles.

Enables clean hydrogen production at scale.

Titanium Dioxide Reduction in Molten Salts

Used in the Kroll and FFC-Cambridge processes to produce metallic titanium from TiO₂.

Electrolyte: NaCl-CaCl₂, high temperature (~900°C).

Cathode collects reduced titanium metal.

Chlor-Alkali Process

Ti-based anodes with RuO₂/IrO₂ coating used to generate chlorine gas and caustic soda efficiently.

Highly resistant to chloride attack.

Electroplating & Surface Treatment

Used in precision plating of metals like gold, silver, or copper on various substrates.

Mesh or sheet electrodes ensure uniform current distribution.

FAQs – Electrolysis with Titanium Electrode

Why use titanium electrodes for electrolysis?

Titanium offers high corrosion resistance, structural integrity, and can be coated for enhanced catalytic activity in various electrolytic reactions.

Can Ti Time customize electrode shape and coating?

Yes. Ti Time provides custom-cut electrodes with tailored coatings, dimensions, and hole patterns for your specific electrolysis setup.

What coatings are available on titanium electrodes?

Common coatings include MMO (RuO₂, IrO₂, Ta₂O₅, Pt) and platinum plating, selected based on chemical compatibility and reaction requirements.

Are Ti Time electrodes suitable for molten salt electrolysis?

Yes. Ti Time manufactures high-temperature resistant electrodes for TiO₂ reduction and other molten salt-based metal recovery systems.

Do you offer bulk supply and international shipping?

Absolutely. Ti Time supplies industrial-scale quantities and supports global logistics with full documentation and quality assurance.

Why Choose Ti Time as Your Electrolysis Titanium Electrode Supplier?

Over 10 years of experience in titanium electrode manufacturing

R&D-driven design and coating optimization

Full custom production capabilities (material, size, shape, coating)

Fast delivery and global support

Trusted by clients in aerospace, energy, metallurgy, and chemical industries

Whether you need precision-engineered electrodes for clean hydrogen production, industrial chlorine generation, or molten salt reduction of titanium dioxide, Ti Time Company is your go-to electrolysis with titanium electrode supplier. With advanced coating technology, full customization, and strict quality standards, Ti Time helps you achieve consistent, efficient, and long-lasting electrochemical performance.