1. Experience in Aerospace Titanium Supply

With over 15 years in the titanium manufacturing industry, Ti Time Company has supplied aerospace-grade titanium products for Boeing, Airbus, and defense aviation programs. We understand the stringent requirements of the aerospace sector, from engine components to airframe structures, and ensure our titanium meets ISO 9001 and AS9100 certifications.

2. Expertise in Titanium for Aircraft Applications

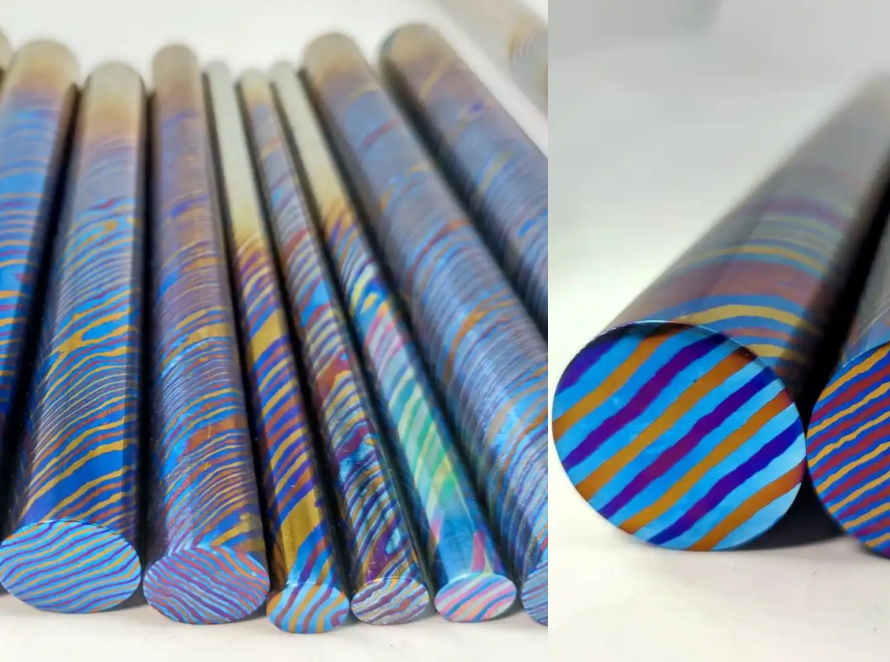

We provide titanium in various forms—sheets, plates, rods, bars, and precision-machined parts—tailored for aviation use. The most common alloy we supply for aerospace is Ti-6Al-4V (Grade 5), which accounts for nearly 50% of titanium alloys used in aircraft due to its superior strength-to-weight ratio and heat resistance.

Applications include:

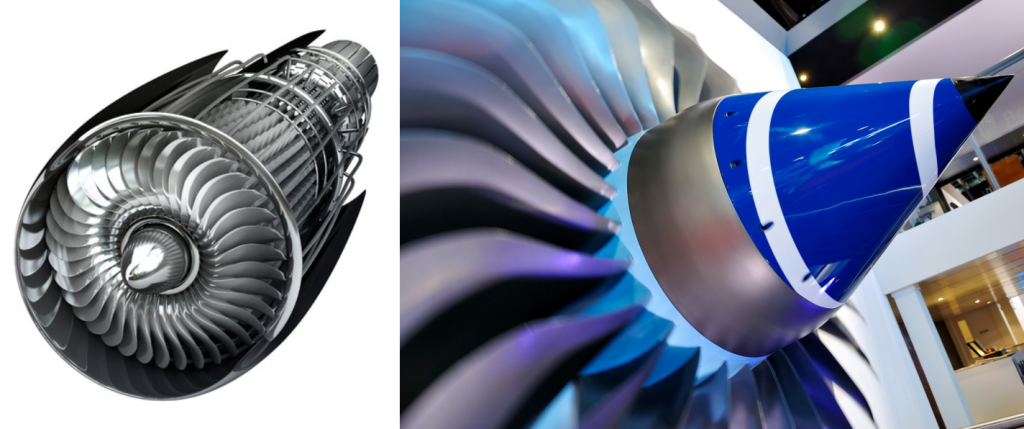

Engine components: compressor blades, turbine disks, fan cases, nacelles

Airframe structures: fuselage frames, wing spars, landing gear beams

Hydraulic systems & firewalls for high-temperature zones

Fasteners & critical joints for weight reduction without compromising safety

3. Authoritative Standards & Quality

All our titanium products are compliant with:

ASTM B348 (titanium bars and rods)

ASTM B265 (titanium plates and sheets)

AMS 4928 / AMS 4911 (aerospace titanium standards)

ISO 9001 & AS9100 quality systems

Every batch comes with a Mill Test Certificate (MTC) and full material traceability.

4. Trustworthiness & Global Client Base

Our titanium is trusted by aviation OEMs and aerospace subcontractors worldwide. We ensure:

Consistent quality & on-time delivery

Competitive pricing for aerospace-grade titanium

Custom fabrication & CNC machining services

Technical consultation on alloy selection and design optimization

5. Why Titanium is Essential in Aircraft Manufacturing

High strength-to-weight ratio: 45% lighter than steel, yet equally strong

Corrosion resistance: Extends service life in harsh environments

High temperature performance: Withstands engine heat and supersonic speeds

Fatigue resistance: Endures millions of stress cycles without failure

FAQs – Titanium Used in Aircraft Supplier

What titanium alloys do you supply for aircraft?

We mainly supply Ti-6Al-4V (Grade 5), Grade 9, and Grade 2 for different aerospace applications.

Do you provide certification for aerospace titanium?

Yes. All products include MTC and comply with AMS and ASTM aerospace standards.

3. Can you produce custom titanium aircraft parts?

Yes. We offer CNC machining, forging, and precision fabrication for aircraft-grade components.

4. How does titanium benefit aircraft design?

It reduces weight, increases fuel efficiency, resists corrosion, and withstands extreme operational temperatures.

5. Do you supply to both commercial and military aviation sectors?

Yes. We supply titanium materials and parts for commercial airliners, private jets, and military aircraft.