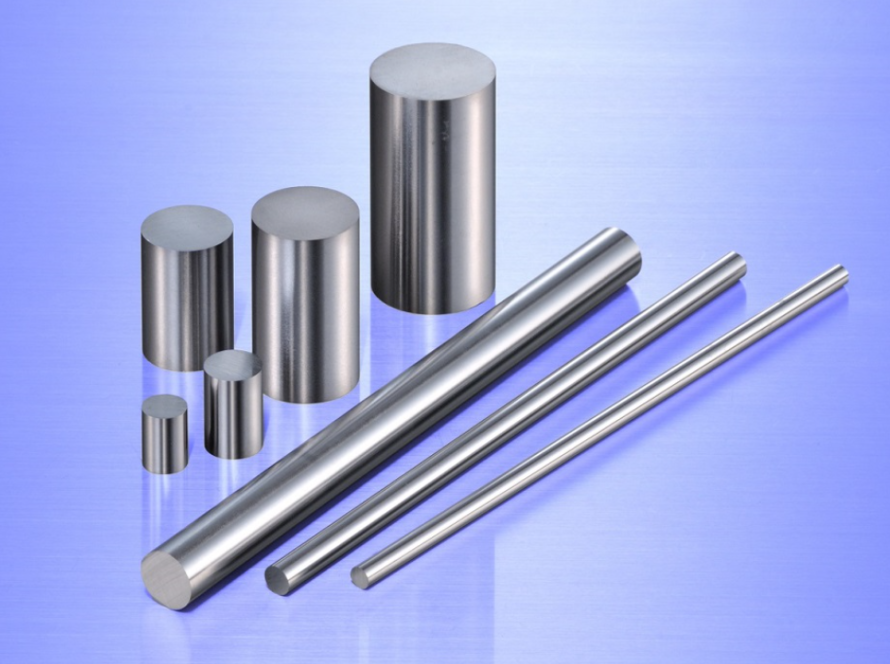

Molybdenum (Mo) is a silvery-grey transition metal with an atomic number of 42 and a melting point of 2623°C, making it one of the most heat-resistant elements. While not a traditional precious metal like gold or silver, molybdenum is considered industrially precious for its critical role in high-performance alloys, aerospace materials, and energy systems.

As a leading molybdenum precious metal supplier, Ti Time Company specializes in custom manufacturing and alloy solutions using molybdenum, tungsten, and titanium materials. We combine deep experience, professional expertise, strong authoritativeness, and proven credibility to serve industries requiring precision metals with extreme strength, durability, and corrosion resistance.

Why Choose Ti Time Company as Your Molybdenum Precious Metal Supplier

Ti Time Company has extensive industry experience producing molybdenum and tungsten carbide metal products, serving aerospace, nuclear, and energy clients worldwide.

Our team of metallurgical engineers provides technical expertise in molybdenum alloy composition, purity control, and high-temperature performance.

Recognized globally as a trusted supplier of refractory and precious industrial metals, Ti Time Company maintains certified production processes and industry-leading material data.

From raw material sourcing to precision machining, our entire production chain ensures traceability, transparency, and ISO-certified quality assurance.

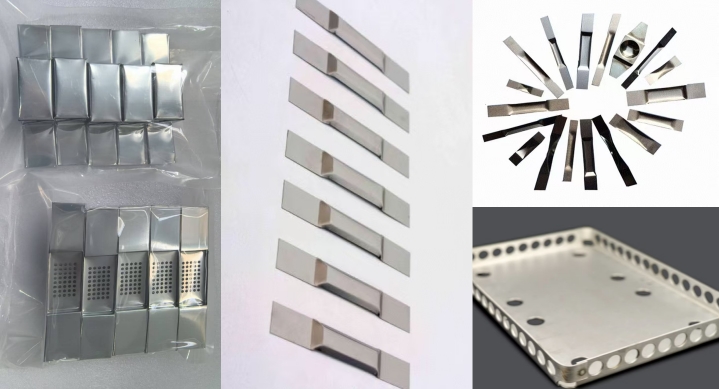

We offer custom molybdenum products designed for extreme environments, including superalloys, thermal shields, electrodes, and precision components.

Industrial Importance of Molybdenum

Unlike traditional precious metals valued for rarity, molybdenum’s worth lies in its performance. It enhances the strength, hardness, and corrosion resistance of steels and superalloys, enabling use in:

Aerospace and Defense – jet engines, turbine blades, and high-stress components.

Nuclear and Energy Systems – reactor parts and heat exchangers.

Renewable Technologies – thin-film solar cells and hydrogen catalysts.

Industrial Tooling – molds, electrodes, and advanced machining tools.

Molybdenum’s durability and resistance to high temperatures make it indispensable in modern engineering applications.

FAQs – Molybdenum Precious Metal & Supplier Services

Q1: Is molybdenum a precious metal?

A1: Technically, molybdenum is not classified as a precious metal like gold or silver. However, it is considered industrially precious due to its high melting point, strength, and vital applications in modern industries.

Q2: What are molybdenum’s main industrial uses?

A2: Molybdenum is used in steel alloys, aerospace components, power generation systems, and renewable energy technologies.

Q3: Why choose Ti Time Company as your molybdenum precious metal supplier?

A3: Ti Time Company offers decades of experience, global credibility, and customized production of molybdenum, tungsten, and titanium-based materials.

Q4: Does Ti Time Company provide customized molybdenum products?

A4: Yes. We provide custom molybdenum manufacturing based on client specifications, including dimensions, alloy composition, and performance requirements.

Q5: How does Ti Time Company ensure quality and credibility?

A5: Every molybdenum product undergoes metallurgical analysis, purity verification, and mechanical testing under certified quality systems to ensure long-term performance reliability.

As a globally recognized molybdenum precious metal supplier, Ti Time Company delivers technically advanced, high-purity molybdenum materials for demanding industries. With unmatched experience, metallurgical expertise, and manufacturing authority, we provide customized solutions that ensure strength, reliability, and precision under extreme conditions. Whether you need tungsten carbide metal or molybdenum alloy components, Ti Time Company is your trusted partner in performance metals.