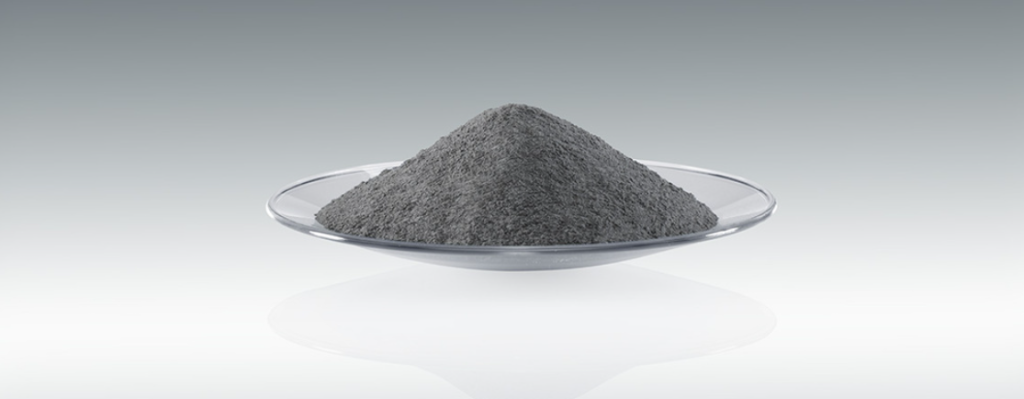

Overview of Molybdenum Powder

Molybdenum powder is a highly versatile metallic material used as a feedstock in alloys, ceramics, coatings, catalysts, and powder metallurgy applications.

With its high melting point (~2623°C), superior strength, and excellent electrical and thermal conductivity, molybdenum powder is critical in manufacturing high-temperature, wear-resistant, and corrosion-resistant components.

Depending on its production method and form, molybdenum powder can be:

-

Pure molybdenum powder (≥99.95% purity) for general metallurgical and electronic uses.

-

Spherical molybdenum powder for additive manufacturing (3D printing) and thermal spray coatings, offering excellent flowability.

-

Alloyed molybdenum powders with titanium, tungsten, or zirconium for enhanced mechanical and oxidation resistance.

Key Properties of Molybdenum Powder

🔥 Ultra-high melting point: ~2623°C, suitable for extreme-temperature environments.

💪 High strength and hardness: Maintains mechanical integrity at elevated temperatures.

⚙️ Excellent thermal & electrical conductivity: Ideal for electronics and heat management systems.

🧪 Corrosion and oxidation resistance: Provides durability in harsh chemical and thermal environments.

⚖️ Adjustable particle size and morphology: From sub-micron to tens of microns for tailored performance in sintering, coating, and additive manufacturing.

Production Methods

Molybdenum powder is produced primarily through:

Hydrogen reduction of molybdenum oxides (MoO₃ → Mo) for fine, high-purity powders.

Gas atomization, which creates spherical powders with excellent flow and uniform packing—perfect for additive manufacturing and plasma spraying.

Mechanical milling or alloying, used to introduce specific additives for customized performance.

Applications of Molybdenum Powder

Additive Manufacturing (3D Printing): Spherical Mo powder used for laser or electron beam fusion to build dense, high-temperature parts.

Powder Metallurgy (PM): Produces high-strength components such as dies, nozzles, and furnace fixtures.

Alloys & Coatings: Enhances steel, superalloy, and ceramic composite performance with improved creep strength and corrosion resistance.

Catalysis & Chemical Processing: Serves as a precursor for Mo-based catalysts and compounds.

Electronics & Thermal Management: Used in contacts, heat spreaders, and substrates due to its conductivity and thermal stability.

Ti Time Company – Professional Molybdenum Powder Supplier

Ti Time Company is a leading manufacturer and supplier of molybdenum powder, offering customized production to meet the specific needs of global industries.

We specialize in high-purity, spherical, and alloyed molybdenum powders, engineered for consistency, purity, and performance.

Our strengths include:

✅ Experience: Over a decade of expertise in refractory metal manufacturing and powder technology.

⚙️ Expertise: Advanced control of particle size distribution, morphology, and chemical purity.

🧾 Authoritativeness: Trusted supplier to industries such as aerospace, energy, electronics, and defense.

🤝 Credibility: ISO-certified processes ensure stable quality and on-time global delivery.

We provide tailor-made molybdenum powder solutions—including custom particle sizes, purity levels, and alloy compositions—to meet unique customer applications.

FAQs About Molybdenum Powder

1. What is molybdenum powder used for?

Molybdenum powder is used in additive manufacturing, powder metallurgy, catalysts, coatings, and high-temperature alloys, providing strength, conductivity, and heat resistance.

2. How is molybdenum powder produced?

It is primarily made by reducing molybdenum oxides with hydrogen or carbon, or by gas atomization to form spherical particles for better flow and sintering.

3. What factors affect molybdenum powder quality?

Particle size, purity, oxygen content, and morphology influence sintering behavior, density, and performance of the final product.

4. Does Ti Time Company provide custom molybdenum powders?

Yes. Ti Time Company offers customized molybdenum powder production, including controlled particle sizes (1–100 µm), specific alloy additives, and surface-treated grades.

5. Why choose Ti Time Company as your molybdenum powder supplier?

Ti Time Company provides technical expertise, global reliability, and customization, ensuring high-purity molybdenum powder for any industrial or research application.

Molybdenum powder plays an essential role in high-performance materials science—delivering durability, conductivity, and temperature resistance where conventional metals fail.

With Ti Time Company’s expertise and customized solutions, clients gain access to premium-quality molybdenum powders engineered to meet precise industrial specifications.