High-Performance Nickel-Chromium-Molybdenum Alloys for Demanding Industries

Ti Time Company is a leading manufacturer and supplier specializing in nickel chromium molybdenum alloys, providing customized production and tailored solutions to meet a wide range of industrial requirements. With deep metallurgical expertise and advanced manufacturing capabilities, Ti Time delivers alloys that ensure strength, corrosion resistance, and reliability in extreme environments.

Nickel-chromium-molybdenum (Ni-Cr-Mo) alloys are high-performance materials widely used in chemical processing, aerospace, marine engineering, oil and gas, and power generation. These alloys combine nickel’s toughness, chromium’s oxidation resistance, and molybdenum’s pitting and crevice corrosion resistance, making them ideal for harsh conditions such as acidic, high-temperature, and chloride-rich environments.

Experience and Expertise

With decades of experience in metal alloy production and processing, Ti Time Company has mastered the science of nickel-based alloy design.

Our expertise extends from alloy formulation and melting to powder metallurgy, forging, and precision machining. Each batch is rigorously tested for composition accuracy, grain structure, and performance metrics to ensure consistent quality.

As a trusted supplier, we have established partnerships with clients across industries who demand superior material integrity, traceability, and long-term performance.

Key Features of Nickel-Chromium-Molybdenum Alloys

Exceptional corrosion resistance — especially against chlorides, sulfuric acid, and seawater.

High temperature strength — reliable mechanical properties maintained up to 1000°C.

Excellent weldability and formability, supporting custom fabrication.

Superior resistance to stress corrosion cracking and crevice corrosion.

Long service life in aggressive chemical, thermal, and marine conditions.

Custom Manufacturing and Supply Capabilities

Ti Time Company provides customized manufacturing of nickel-chromium-molybdenum alloys to match your exact specifications.

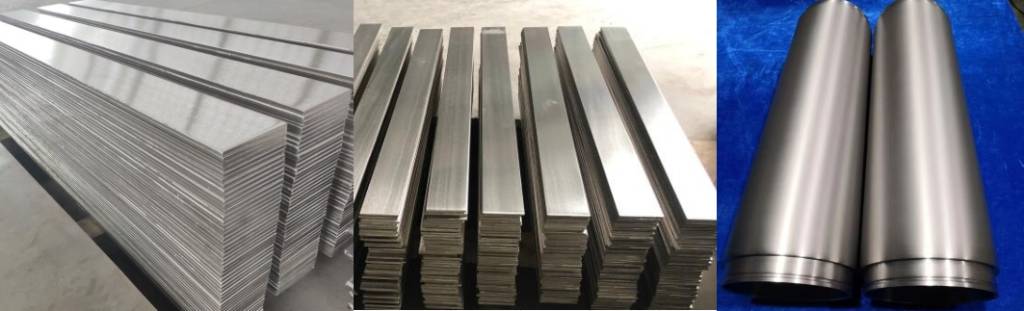

Available forms include:

Bars, plates, and sheets

Pipes, tubes, and fittings

Powder for additive manufacturing

Forged or machined components

We tailor parameters such as composition balance (Ni/Cr/Mo ratio), grain size, surface finish, and heat treatment to meet client-specific requirements for both standard and proprietary alloy grades.

Applications

Chemical processing: reactors, heat exchangers, valves, and piping exposed to acidic environments.

Aerospace: turbine components, exhaust systems, and hot-section fasteners.

Marine: seawater-facing structures, pump housings, and fittings.

Oil & Gas: offshore platforms, subsea connectors, and corrosive fluid lines.

Power generation: superheater tubes, steam headers, and high-temperature vessels.

FAQs – Nickel Chromium Molybdenum Alloys Supplier

1. What makes nickel-chromium-molybdenum alloys superior to stainless steel?

These alloys offer significantly better corrosion resistance, especially against chlorides and reducing acids, along with greater strength retention at elevated temperatures compared to most stainless steels.

2. Can Ti Time Company provide custom alloy compositions?

Yes. Ti Time specializes in custom alloy design based on your corrosion environment, mechanical requirements, and fabrication method.

3. What quality control measures are used?

We use spectroscopic analysis, ultrasonic inspection, and tensile testing to ensure every product meets international standards like ASTM, ASME, and ISO.

4. Do you supply alloy powders for additive manufacturing?

Yes. We provide spherical Ni-Cr-Mo alloy powders optimized for laser or electron beam melting with excellent flowability and purity.

5. What industries rely most on Ti Time Company’s nickel-chromium-molybdenum alloys?

Major sectors include chemical processing, marine, aerospace, energy, and petrochemical industries that demand durability under harsh service conditions.

Why Choose Ti Time Company

Proven manufacturing excellence with advanced melting and atomization technologies.

In-house materials laboratory for chemical and mechanical testing.

Commitment to on-time delivery and global logistics support.

Reliable technical consultation for alloy selection and application optimization.

When performance, corrosion resistance, and quality are non-negotiable — Ti Time Company is your dependable nickel chromium molybdenum alloys supplier.