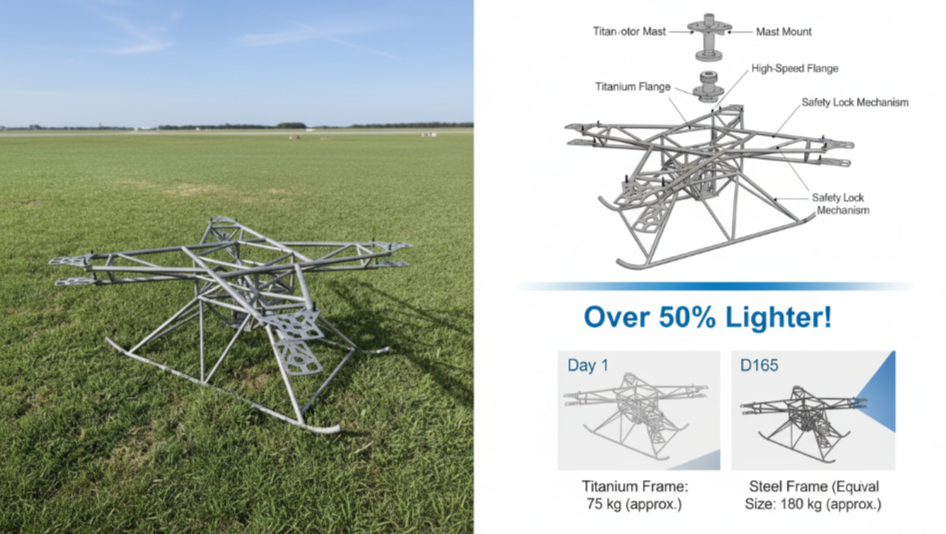

Elevating Flight: The Ultimate Guide to Titanium Materials for Gyrocopter Frames

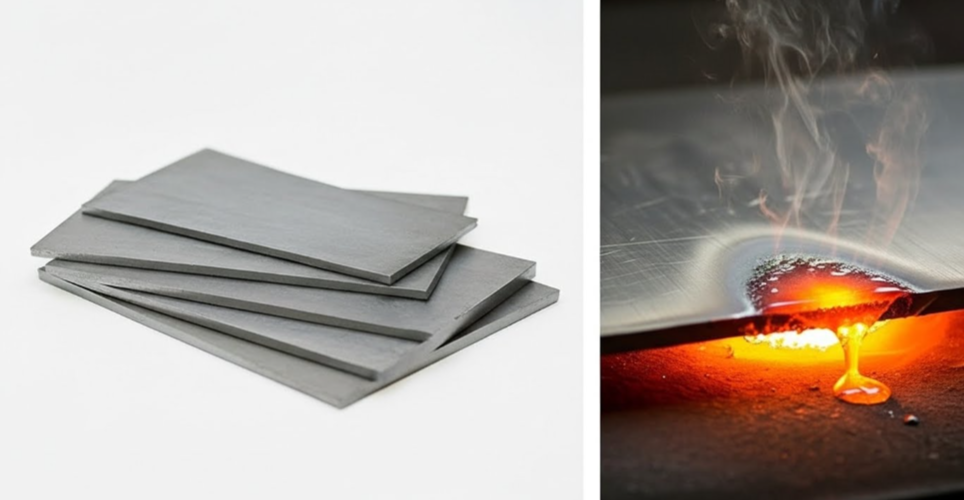

In the world of rotorcraft aviation, the margin for error is non-existent. Engineers and pilots increasingly turn to a Titanium materials Gyrocopter Frame to achieve the perfect balance of lightweight agility and structural invincibility. Unlike traditional 4130 steel or aluminum, titanium offers a unique…