Tungsten metal rings have become a top choice in modern jewelry for their exceptional hardness, scratch resistance, and sleek metallic finish. Known for being nearly as dense as gold and significantly more durable than silver or platinum, tungsten rings combine luxury, strength, and affordability.

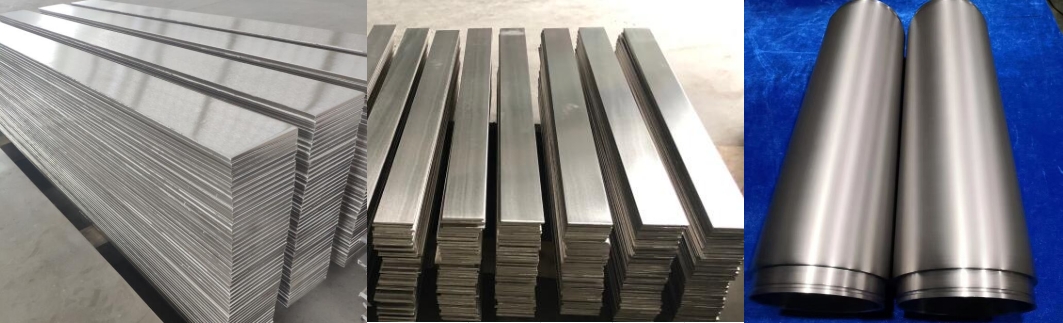

As tungsten prices rise due to global supply constraints, finding a…