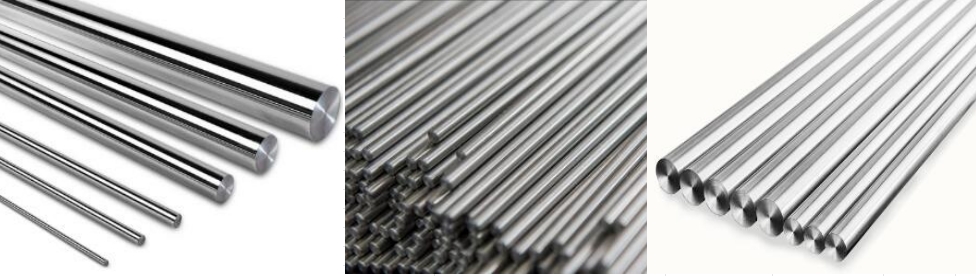

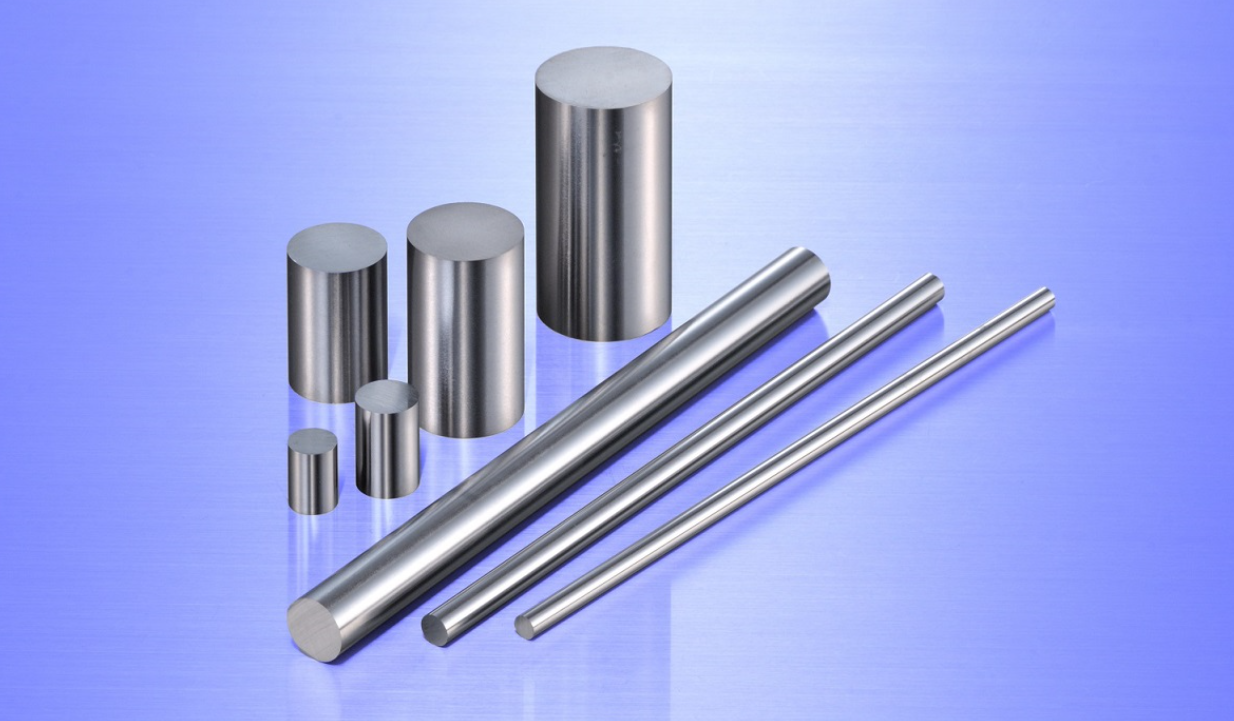

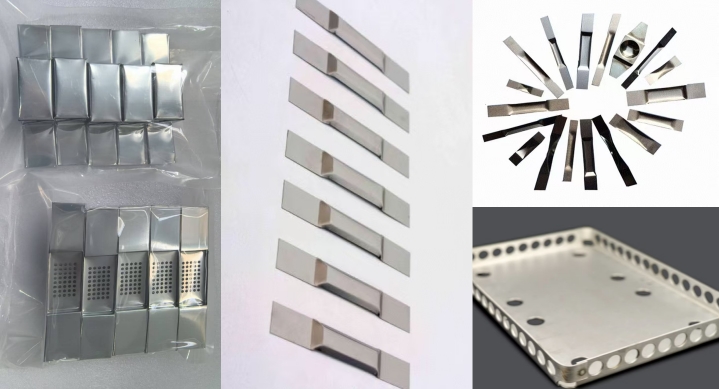

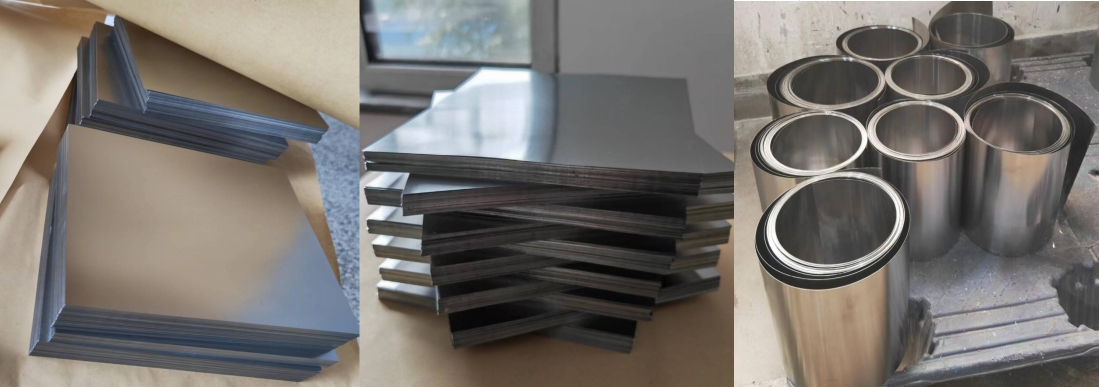

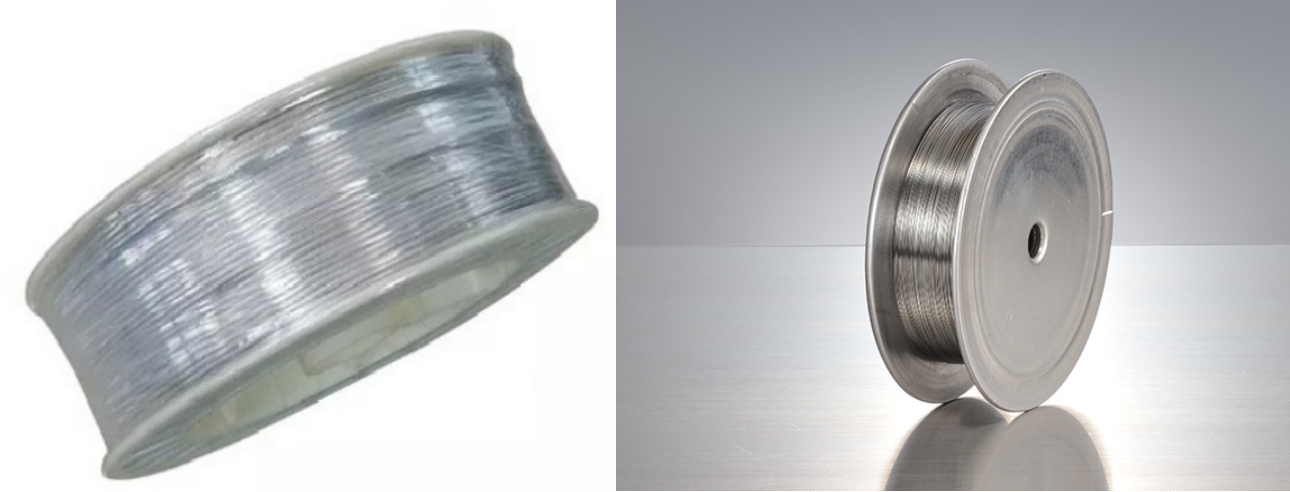

Ti Time Company is a professional manufacturer and supplier of cobalt chromium molybdenum (Co–Cr–Mo) alloys, delivering high-performance materials engineered for biomedical implants, aerospace, and industrial wear-resistant components. With deep metallurgical experience and advanced production capabilities, Ti Time provides customized Co–Cr–Mo alloy products designed to meet strict industry standards such as ASTM F75, F799, and ISO…