Electropolishing titanium is a precision electrochemical finishing process that enhances the surface of titanium components by removing micro-imperfections, embedded impurities, and oxide layers. It is essential for industries that require ultra-smooth, corrosion-resistant, and sterile surfaces, such as medical, aerospace, semiconductor, and chemical processing.

As a trusted titanium supplier, Ti Time Company specializes in both raw titanium material and electropolished titanium parts, offering fully customized electropolishing services for high-performance applications.

What is Titanium Electropolishing?

Electropolishing is an anodic dissolution process, where titanium is connected as the anode and immersed in a specially formulated electrolyte. Under controlled voltage and temperature, microscopic peaks on the titanium surface are preferentially dissolved, leading to:

📌 Ultra-smooth finishes (Ra ≈ 30 nm)

📌 Bright, reflective appearance

📌 Improved corrosion resistance

📌 Clean, contaminant-free surfaces

How Electropolishing Titanium Works

| Step | Description |

|---|---|

| Pre-Treatment | Mechanical polishing with 400–1200 grit sandpaper + water rinse |

| Electrolyte Bath | Commonly perchloric acid–methanol, glycol–HF, or Na-tartrate solutions |

| Voltage Application | 10–120V applied while maintaining a bath temperature of 10–40°C |

| Polishing Time | From 3 minutes (surface finishing) to several hours (deep smoothing) |

| Post-Treatment | Water rinsing, ultrasonic cleaning, and drying for final finish |

Common Electrolytes for Titanium Electropolishing

Perchloric Acid–Methanol–Butanol: High polish quality, low temp (-40°C), requires strict safety protocols.

Perchlorate-Free Solutions: Safer alternatives using methanol + sulfuric acid or sodium tartrate.

Glycol–HF Mixes: Suitable for thin titanium parts and controlled surface removal.

Key Process Parameters

| Parameter | Typical Range | Notes |

|---|---|---|

| Voltage | 10–120 V | Higher voltage for deeper removal |

| Temperature | 10–40°C (or -40°C) | Sub-zero for perchloric-based methods |

| Time | 3–10 mins to hours | Based on part complexity |

| Agitation | 0–600 rpm | Promotes uniformity |

| Surface Roughness | Ra ≈ 30 nm | Post-process, smoother than mechanical polishing |

Benefits of Electropolished Titanium

Corrosion Resistance: Enhanced passive oxide layer.

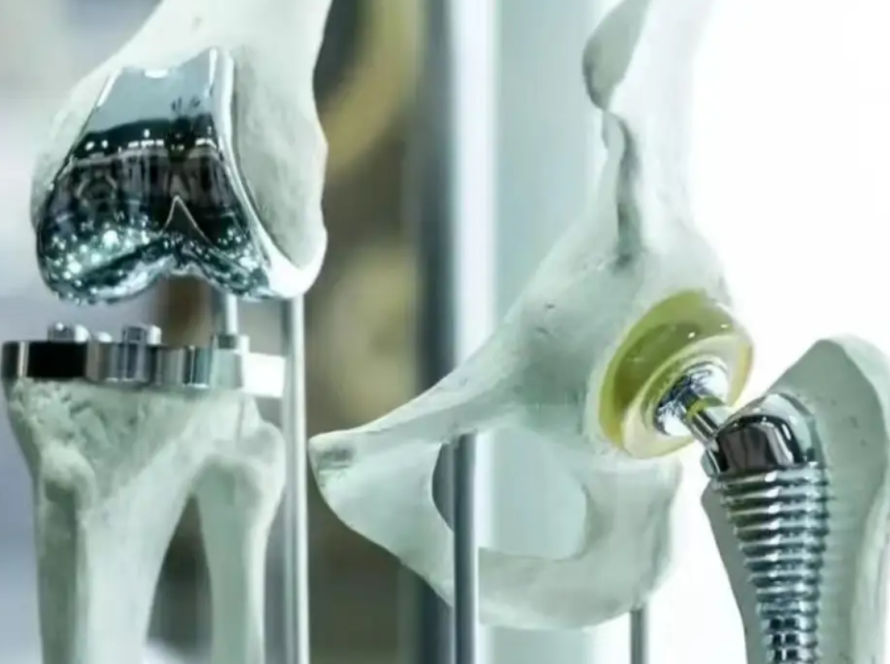

Biocompatibility: Critical for implants and surgical tools.

Aesthetic Quality: Bright, mirror-like appearance.

Deburring: Removes micro-burrs, sharp edges.

Contaminant-Free Surfaces: For semiconductor, optical, and cleanroom applications.

Applications by Industry

| Industry | Application Examples |

|---|---|

| Medical | Implants, dental screws, surgical scissors |

| Aerospace | Engine parts, airframe components |

| Semiconductors | Sensor housings, optical mounts |

| Chemical | Reactor internals, high-purity process fittings |

Ti Time Company: Titanium Electropolishing Expertise

Ti Time Company offers complete titanium fabrication and surface finishing solutions:

🔬 Electropolishing for CP titanium (Grade 1, 2) and alloys (Grade 5, 23)

⚙ Precision polishing services for complex geometries

🧪 Full compliance with ASTM, ISO 13485, and aerospace quality standards

🚚 Global delivery and technical support for OEM and industrial clients

FAQs – Electropolishing Titanium

Is electropolishing better than mechanical polishing for titanium?

Yes. Electropolishing produces smoother, cleaner, and more corrosion-resistant surfaces than mechanical methods, with no risk of introducing abrasive contamination.

What alloys of titanium can be electropolished?

Most commonly electropolished alloys include Grade 2, Grade 5 (Ti-6Al-4V), and Grade 23 (ELI) for medical-grade applications.

Can titanium implants be electropolished for surgical use?

Absolutely. Electropolishing enhances biocompatibility and removes microscopic contaminants, making it ideal for implants.

What safety precautions are needed for perchloric acid-based electrolytes?

Strict temperature control, fume extraction, and non-sparking environments are required. Safer alternatives are available.

Does Ti Time Company offer custom electropolished titanium parts?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Yes. We provide CNC-machined titanium parts with optional electropolishing for OEMs, medtech, and aerospace clients.

Summary

Electropolishing titanium is a critical process for achieving ultra-clean, smooth, and corrosion-resistant surfaces in high-performance industries. As a global titanium supplier, Ti Time Company delivers expert electropolishing services tailored to the most demanding standards—supporting applications from surgical implants to aerospace systems.