What is Electropolishing of Titanium?

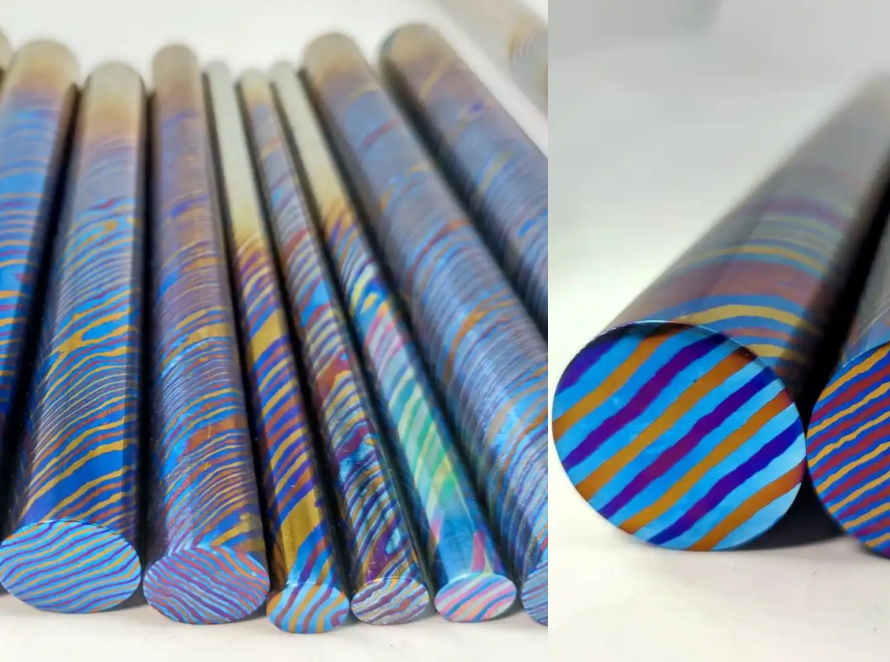

Electropolishing is an electrochemical process where titanium atoms dissolve anodically in an electrolyte, resulting in both macro-scale smoothing and micro-scale polishing. A thin, uniform passive titanium oxide layer (TiO₂) forms during the process, contributing to the metal’s outstanding biocompatibility and corrosion resistance.

Process Overview:

Controlled anodic dissolution of titanium atoms.

Formation and continuous dissolution of TiO₂ passive layer.

Oxygen evolution reaction enhances surface purity.

Common electrolytes: sulfuric acid in methanol or other non-aqueous solvents.

Voltage range: 10–15 volts (optimized at current plateau).

Temperature control, often as low as -20°C, ensures smoother surfaces.

Benefits of Electropolishing Titanium

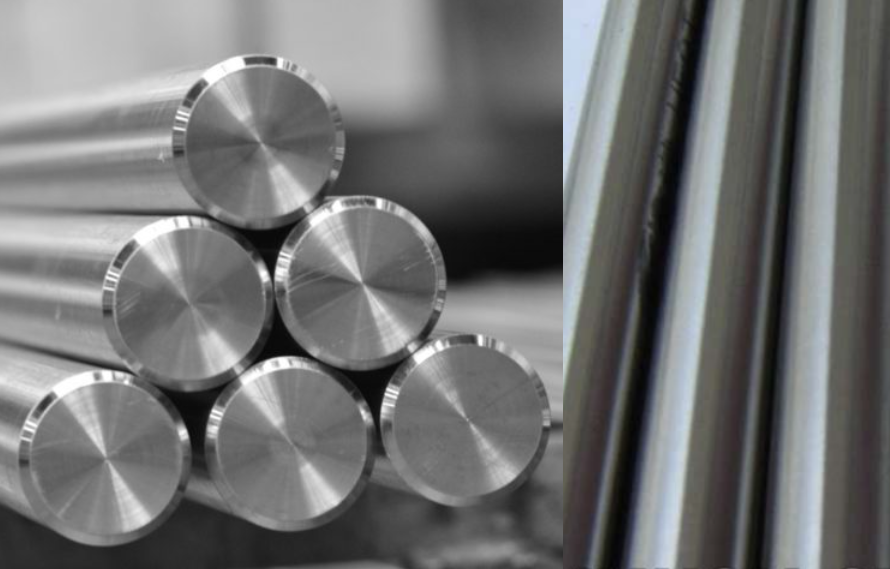

Surface smoothness: Dramatic reduction in roughness (Ra values lowered significantly).

Defect removal: Eliminates scratches, burrs, and machining irregularities.

Enhanced performance: Improves fatigue strength, corrosion resistance, and cleanliness.

Aesthetic finish: Produces a bright, reflective, contamination-free surface.

Biocompatibility: Ideal for medical implants without altering alloy composition.

Challenges in Electropolishing Titanium

raditional use of HF or perchloric acids involves safety hazards.

Process requires strict temperature and current density control.

Complex geometries and internal features demand advanced process optimization.

Ongoing research focuses on eco-friendly electrolytes and safer methods.

Applications of Electropolished Titanium

Electropolished titanium is critical in industries that demand high-performance and biocompatibility:

Medical Implants: Orthopedic screws, dental implants, cardiovascular stents.

Aerospace Components: Precision-engineered Ti 6Al 4V turbine blades, fasteners.

Additive Manufacturing: Smoothing EBM/SLM-produced titanium parts.

Precision Engineering: High-performance parts requiring ultra-clean and smooth finishes.

Ti Time Company – Your Trusted Electropolish Titanium Supplier

At Ti Time Company, we specialize in customized electropolish titanium solutions. With extensive experience, technical expertise, and commitment to innovation, we provide:

Precision electropolishing of Ti 6Al 4V and other titanium grades.

Customized production to meet client-specific applications.

Environmentally conscious and safe polishing processes.

Global supply capabilities with strict quality assurance.

Our reputation is built on Experience, Expertise, Authoritativeness, and Trustworthiness (EEAT), making us the preferred partner for industries requiring high-quality titanium surface finishing.

FAQs About Electropolish Titanium

1. What is electropolishing of titanium?

Electropolishing is an electrochemical process that smooths and polishes titanium surfaces by dissolving surface atoms, leaving a bright and defect-free finish.

2. Why is electropolished titanium used in medical implants?

Because it enhances biocompatibility, reduces bacterial adhesion, and ensures a smooth, corrosion-resistant surface.

3. Can Ti 6Al 4V alloy be electropolished effectively?

Yes. Ti 6Al 4V responds very well to electropolishing, especially under controlled temperature and optimized voltage conditions.

4. What are the environmental concerns in electropolishing?

Traditional processes use hazardous acids, but newer methods use safer, environmentally friendly electrolytes, which Ti Time Company prioritizes.

5. Does electropolishing change the chemical composition of titanium?

No. The process only affects the surface roughness and oxide layer, preserving the alloy’s intrinsic properties.