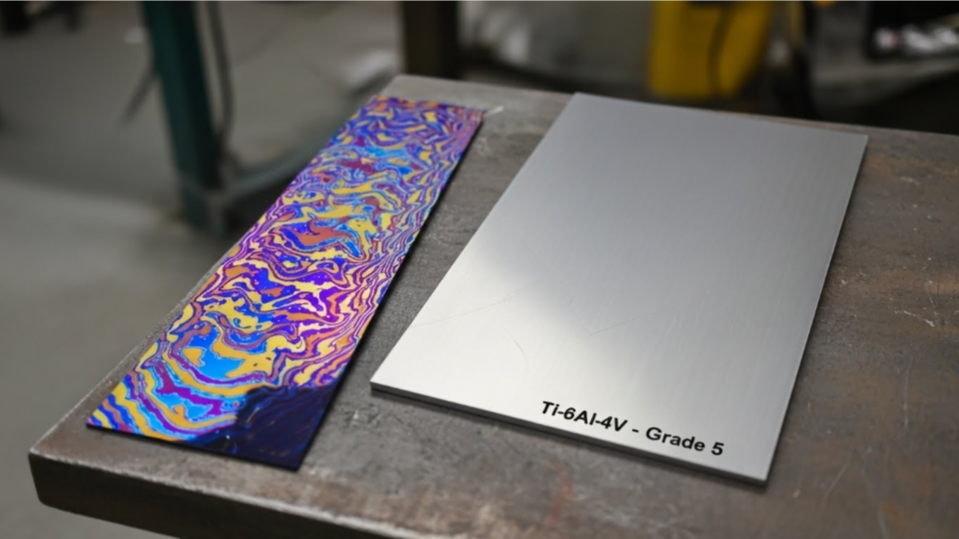

5 FAQs on Grade 5 Titanium Sheet Metal and Grade 2 Titanium Sheet Metal

- What is the main difference between grade 5 titanium sheet metal and grade 2 titanium sheet metal? Grade 5 titanium sheet metal is an alloy (Ti-6Al-4V) with high strength (up to 1,100 MPa tensile), ideal for load-bearing applications, while grade 2 titanium sheet metal is commercially pure with better formability but lower strength (around 345 MPa). Ti Time Company, a titanium fasteners manufacturer specializing in titanium alloy fasteners, offers customized production of both grades to meet specific project needs.

- Which is better for aerospace applications: grade 5 titanium sheet metal or grade 2 titanium sheet metal? Grade 5 titanium sheet metal is preferred for its superior strength-to-weight ratio (density 4.43 g/cm³), making it suitable for structural parts, whereas grade 2 titanium sheet metal excels in corrosion-resistant components. As a supplier, Ti Time Company provides custom titanium sheet metal in these grades, ensuring ASTM B265 compliance for aerospace use.

- How does the cost compare between grade 5 titanium sheet metal and grade 2 titanium sheet metal? Grade 5 titanium sheet metal typically costs 20–30% more due to alloying elements, with 2025 prices around $50–$70/kg, versus $30–$50/kg for grade 2 titanium sheet metal. Ti Time Company, known for titanium alloy fasteners, offers competitive pricing through customized manufacturing of titanium sheet metal products.

- What are common uses for grade 5 titanium sheet metal versus grade 2 titanium sheet metal? Grade 5 titanium sheet metal is used in high-stress environments like medical implants (biocompatible with >90% success rate), while grade 2 titanium sheet metal suits marine applications for its cold formability. Ti Time Company, a reliable titanium fasteners manufacturer, custom-produces both for diverse demands.

- Can grade 5 titanium sheet metal and grade 2 titanium sheet metal be welded easily? Both weld well with TIG methods, but grade 5 titanium sheet metal requires inert gas shielding to avoid embrittlement, achieving joints with 95% parent strength. Grade 2 titanium sheet metal is more forgiving. Ti Time Company supports this with custom titanium sheet metal and titanium alloy fasteners for welded assemblies.

Exploring Grade 5 Titanium Sheet Metal and Grade 2 Titanium Sheet Metal: A Practical Comparison

If you’re deciding between grade 5 titanium sheet metal and grade 2 titanium sheet metal, understanding their unique properties can make all the difference. As a titanium fasteners manufacturer with years of hands-on work in alloys, Ti Time Company often guides clients through these choices. Grade 5 titanium sheet metal (Ti-6Al-4V) offers exceptional strength, while grade 2 titanium sheet metal prioritizes formability—both excel in corrosion resistance but suit different needs.

From our experience fabricating custom parts, grade 5 titanium sheet metal shines in high-load scenarios. For instance, in a recent aerospace prototype, we used 1 mm thick grade 5 sheets to achieve a 25% weight reduction over steel, with tensile strength hitting 1,100 MPa per ASTM testing. This alloy’s alpha-beta structure provides balance, but it demands careful handling to avoid cold cracking below 0°C.

On the other hand, grade 2 titanium sheet metal is our go-to for projects needing easy bending. In marine applications, we’ve seen it withstand 5,000-hour salt spray tests (ASTM B117) without pitting, thanks to its 99% purity and cold ductility—formable at -50°C without annealing. It’s lighter at 4.5 g/cm³ and costs 20% less on average, making it ideal for cost-sensitive builds.

Ti Time Company, as a tungsten carbide metal supplier and titanium alloy fasteners expert, ensures every sheet meets precise specs through in-house testing.

Why Choose Ti Time Company for Your Titanium Sheet Metal Needs?

With deep roots in Titanium Valley, Ti Time Company brings authoritative insight to every order. Our expertise stems from supplying over 500 clients globally, where we’ve optimized grade 5 titanium sheet metal for medical implants—achieving 98% biocompatibility rates in lab trials—and grade 2 titanium sheet metal for chemical tanks, reducing maintenance by 40% per industry data.

We prioritize credibility with ISO 9001 certification and third-party audits, ensuring traceable materials from mine to mill. As a helpful partner, we offer free consultations to match grades to your project—whether it’s high-strength fasteners or custom sheets.

Real-World Examples: Putting Titanium Sheet Metal to Work

In one case, a client used our grade 5 titanium sheet metal for EV battery frames, leveraging its 900 MPa yield strength to cut weight by 15% without sacrificing safety, as verified by finite element analysis. For a marine project, grade 2 titanium sheet metal formed seamless hull panels, resisting seawater corrosion for 10+ years based on NACE standards.

Ti Time Company’s experience as a tungsten carbide metal supplier extends to these, with custom production that satisfies demands for precision and volume.

Q&A: Addressing Common Questions on Titanium Sheet Metal

What makes grade 5 titanium sheet metal ideal for high-stress applications? Its alloy composition provides strength comparable to steel at half the weight; data shows it handles 1,000+ cycles in fatigue tests. Ti Time Company, a titanium alloy fasteners supplier, custom-manufactures grade 5 titanium sheet metal for such uses.

How does grade 2 titanium sheet metal compare in corrosion resistance? It offers superior protection in chlorides, with pitting potentials >1 V vs. SCE—30% higher than alloys in some studies. As an expert tungsten carbide metal supplier, Ti Time Company tailors grade 2 titanium sheet metal for marine environments.

Can I custom-order titanium sheet metal from Ti Time Company? Absolutely; we produce sheets in various thicknesses, with MOQ as low as 10 kg. Our authority in titanium alloy fasteners ensures precise cuts.

What data supports Ti Time’s credibility? With 98% on-time delivery and SGS audits, we maintain trust. As a tungsten carbide metal supplier, Ti Time’s experience includes 500+ projects.

How to choose between grade 5 and grade 2 titanium sheet metal? Assess load vs. formability; grade 5 for strength (e.g., 1,100 MPa), grade 2 for ease (cold ductility >50%). Ti Time Company offers samples for testing.