Industry Applications

Titanium, tungsten, molybdenum, tantalum, niobium, zirconium, anodes, and composite materials are widely used across various industries due to their exceptional properties. Their outstanding corrosion resistance, wear resistance, and high-temperature stability make them ideal for demanding environments.

In the aerospace industry, titanium and its alloys are extensively used in aircraft structures and spacecraft due to their high strength, lightweight, and heat resistance. Tungsten and molybdenum are critical for rocket nozzles and turbine blades. In the medical field, titanium’s biocompatibility makes it suitable for artificial joints and dental implants, while tantalum is used in pacemakers and other implantable devices. The marine industry relies on titanium and zirconium for their excellent corrosion resistance in oceanic environments, applied in platforms and deep-sea exploration equipment. In the chemical industry, titanium, zirconium, and tantalum maintain stability in highly acidic or alkaline conditions, commonly used in reactors and heat exchangers.

In the automotive industry, titanium and composite materials enhance performance by reducing weight and increasing strength, making them particularly valuable for high-performance vehicles. In the consumer goods and construction industries, titanium is used for durable, modern designs in electronics, eyewear, and architectural cladding.

Ti Time is committed to delivering high-quality material solutions to meet diverse industry needs, enabling customers to achieve innovation and market growth.

Aerospace

itanium and its alloys are used in aircraft fuselages, engine components, and spacecraft structures, offering high strength and heat resistance. High-temperature-resistant materials like tungsten and molybdenum are applied in rocket nozzles and turbine blades.

Medical Field

Titanium's biocompatibility makes it widely used in artificial joints, bone screws, and dental implants. Tantalum's corrosion resistance makes it an ideal choice for pacemakers and implantable devices.

Marine Industry

Titanium and its alloys exhibit excellent corrosion resistance in seawater, used in manufacturing marine platforms, ship hulls, and submarine equipment. Zirconium is utilized in nuclear submarines and deep-sea exploration equipment.

Chemical Industry

Titanium, zirconium, and tantalum maintain high stability in strong acidic and alkaline environments, used in reactors, pipelines, and heat exchangers.

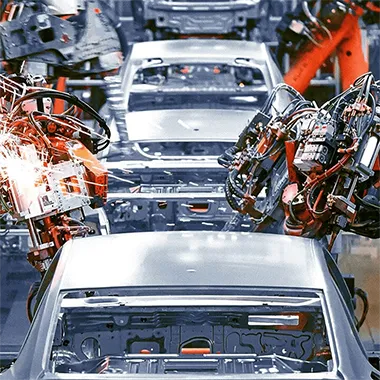

Automotive Industry

Titanium and composite materials are used to reduce weight and enhance strength in high-performance vehicle engines and exhaust systems. Molybdenum alloys are applied to reinforce vehicle structures and improve durability.

Consumer Goods Industry

Titanium's lightweight and durability make it ideal for eyeglass frames, watches, and sports equipment. Composite materials are used in high-end consumer electronics casings and accessories.

Construction Industry

Titanium alloys are applied in building curtain walls and roofs, offering a unique appearance and corrosion resistance. Composite materials achieve lightweight and high-strength requirements for building structures.

Oil and Gas

In the oil and gas industry, titanium and its alloys, along with high-temperature-resistant materials like tungsten and molybdenum, provide reliable and high-quality solutions for titanium pipes, flanges, and fasteners.

Titanium Supplier Can be Easy & Safe

Regardless of the type of titanium product you need, our extensive experience allows us to manufacture it. In particular, since we produce our own raw materials, we can offer better pricing and quality control than our global competitors.