In modern engineering, few materials demand as much respect—and expertise—as titanium. Engineers choose titanium not because it is easy to process, but because it delivers performance that other metals cannot match. High strength at low weight, exceptional corrosion resistance, and proven biocompatibility make titanium indispensable in aerospace, medical, marine, and advanced industrial applications.

Turning titanium’s theoretical advantages into reliable, repeatable components requires far more than standard machining capability. As an experienced machined titanium supplier and titanium fabrication supplier, Ti Time Company transforms titanium mill products into precision parts and complex assemblies that perform in real-world operating conditions.

Machined Titanium vs. Titanium Fabrication: An Engineering Perspective

Although often mentioned together, machined titanium and titanium fabrication serve different engineering purposes.

Machined titanium focuses on precision. Using CNC milling, turning, drilling, and multi-axis machining, manufacturers remove material to achieve tight tolerances, complex geometries, and critical surface finishes. These components frequently operate under high stress, extreme temperatures, or strict dimensional requirements.

Titanium fabrication, by contrast, emphasizes structural formation. Fabricators cut, form, weld, and assemble titanium sheets, plates, bars, and tubes into frames, housings, pressure vessels, and large-scale assemblies. Successful fabrication depends on deep metallurgical knowledge, controlled environments, and disciplined process management.

Ti Time Company integrates both capabilities, allowing clients to source finished titanium components—from small, high-precision parts to large fabricated structures—from a single, accountable partner.

Why Engineers Rely on Titanium

Titanium continues to replace heavier or less durable materials because it delivers measurable engineering advantages:

Strength Without Weight Penalty

Alloys such as Ti-6Al-4V (Grade 5) provide steel-level strength at roughly 60% of the weight, enabling lighter designs without compromising safety or durability.Exceptional Corrosion Resistance

Titanium forms a stable oxide layer that resists saltwater, chemicals, and extreme environments, dramatically extending service life.Proven Biocompatibility

Medical designers trust titanium because the human body accepts it. Implants integrate with bone while maintaining long-term structural integrity.

These characteristics explain why industries with zero tolerance for failure continue to invest in machined titanium parts and fabricated titanium systems.

Titanium Applications That Demand Precision

Engineers across industries rely on titanium when failure is not an option:

Aerospace

Structural components, fasteners, engine parts, and compressor elements benefit from titanium’s strength-to-weight advantage and fatigue resistance.Medical & Dental

Implants, fixation devices, surgical instruments, and dental components depend on precision machining and certified biocompatible materials.Marine & Chemical Processing

Heat exchangers, reactors, and offshore hardware use fabricated titanium to withstand corrosive environments over decades of service.High-End Consumer & Industrial Products

Premium watches, sporting equipment, eyewear, and specialty tools leverage titanium for durability, aesthetics, and performance.

Ti Time Company supports these sectors with both standard and fully customized titanium solutions, tailored to application-specific demands.

The Reality of Machining Titanium—and How Ti Time Solves It

Titanium does not behave like steel or aluminum on the machine floor. Manufacturers who underestimate it quickly encounter problems.

In real production environments, titanium:

Retains heat at the cutting edge, accelerating tool wear

Hardens under stress, increasing cutting forces

Punishes unstable setups and inconsistent parameters

Ti Time Company overcomes these challenges through disciplined process control and investment in the right technology. High-torque CNC machines, optimized cutting strategies, advanced coolant delivery, and rigid fixturing allow our team to machine titanium efficiently while maintaining tight tolerances and consistent surface quality.

Beyond machining, Ti Time Company provides secondary operations such as anodizing, polishing, and surface finishing—enhancing wear resistance, appearance, and functional performance.

Titanium Fabrication: Control from Material to Assembly

Successful titanium fabrication requires more than welding skills. It demands environmental control, metallurgical discipline, and procedural rigor.

Ti Time Company delivers comprehensive fabrication capabilities, including:

Precision Cutting & Forming

Waterjet and laser cutting, bending, forging, and stamping for consistent material behavior and dimensional accuracy.Advanced Welding & Joining

TIG (GTAW), electron beam, and friction welding performed under controlled inert gas protection to prevent contamination and embrittlement.Sheet Metal & Structural Fabrication

Brake forming, roll forming, and deep drawing for enclosures, housings, and load-bearing assemblies.

From Kroll-process titanium sponge to finished components, Ti Time Company maintains full material traceability and strict quality oversight at every stage.

Why Global Buyers Choose Ti Time Company

Choosing a titanium supplier means choosing long-term reliability. Ti Time Company earns that trust through proven capability and transparent execution.

Demonstrated Experience

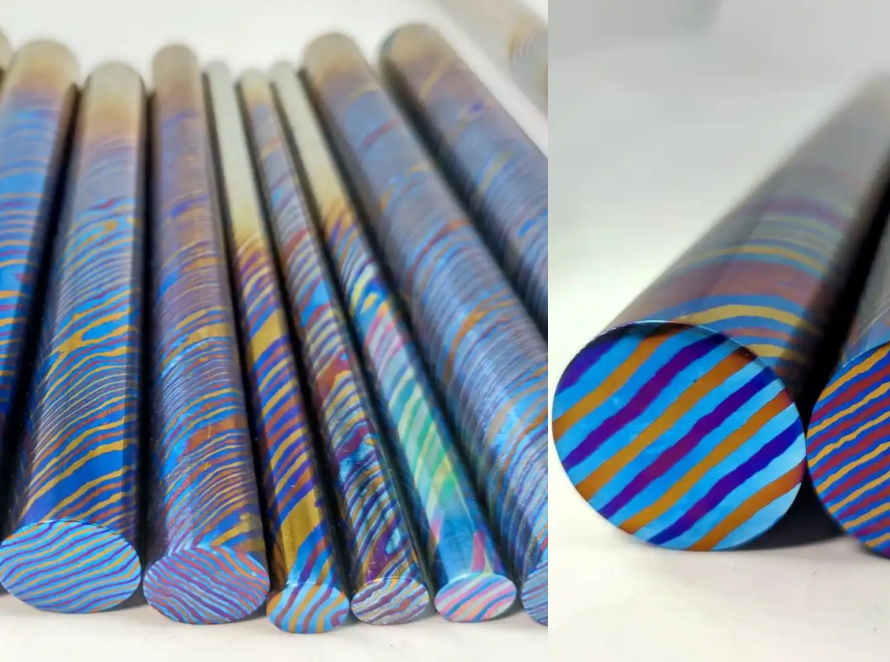

Over two decades of hands-on work in titanium metallurgy, machining, and fabrication.Deep Technical Expertise

Proficiency with commercially pure titanium, Ti-6Al-4V, medical-grade alloys, and advanced materials such as Timascus.Authoritative Quality Systems

ISO-aligned processes, certified materials, rigorous inspection, and documented traceability.Operational Trustworthiness

Clear communication, stable lead times, flexible production volumes, and consistent delivery performance.

From rapid prototypes to high-volume production, Ti Time Company supports customers who demand precision without compromise.

Frequently Asked Questions

What distinguishes machined titanium from titanium fabrication?

Machined titanium focuses on high-precision subtractive processes, while titanium fabrication forms and assembles larger structures using cutting, welding, and forming techniques.

Why work with Ti Time Company as a machined titanium supplier?

Because we understand titanium’s real machining behavior and control every variable required to achieve tight tolerances and repeatable quality.

Which titanium alloys do you support?

Ti Time Company works extensively with Ti-6Al-4V, commercially pure grades, medical-grade titanium, and specialty alloys such as Timascus.

Do you support custom titanium fabrication projects?

Yes. We provide end-to-end support—from engineering consultation to finishing—for both low-volume and large-scale production.

How do you ensure consistent quality?

Through certified materials, controlled processes, in-process inspection, and final testing aligned with international standards.