Overview of Molybdenum Alloy Properties

Molybdenum alloys are advanced metallic materials primarily composed of molybdenum (Mo) combined with elements like titanium, zirconium, rhenium, tungsten, hafnium, carbon, and other rare metals. These alloys are engineered to enhance the mechanical strength, thermal stability, electrical conductivity, and corrosion resistance of pure molybdenum, enabling exceptional performance under extreme conditions.

With its high melting point (2623°C) and low thermal expansion coefficient, molybdenum serves as a foundation for alloys that perform reliably in aerospace, nuclear, electronic, and high-temperature manufacturing environments.

Key Molybdenum Alloy Types and Their Properties

1. Molybdenum Rhenium (Mo-Re) Alloy

Composition: 11–50% rhenium.

Features enhanced ductility, weldability, and resistance to brittleness at low temperatures.

Exhibits superior creep strength and thermal stability up to extreme heat levels.

Applications: Rocket nozzles, turbine blades, electronic components, and nuclear reactor parts.

2. Titanium Zirconium Molybdenum (TZM) Alloy

Contains molybdenum with titanium, zirconium, and carbon additives.

Excellent strength, thermal/electrical conductivity, corrosion resistance, and low vapor pressure.

Applications: Aerospace engines, high-temperature dies, and glass processing components.

3. Molybdenum Copper (Mo-Cu) Alloy

Combines molybdenum’s mechanical strength with copper’s thermal and electrical conductivity.

Applications: Heat sinks, electronic contacts, and power semiconductor bases.

4. Molybdenum Tungsten (Mo-W) Alloy

Integrates tungsten’s hardness and wear resistance with molybdenum’s light weight and machinability.

Applications: High-speed cutting tools, furnace parts, and structural machinery under thermal stress.

5. Molybdenum Hafnium Carbon (MHC) Alloy

Offers superior creep resistance and thermal stability, ideal for nuclear and aerospace components requiring long-term high-temperature reliability.

6. Molybdenum Single-Crystal Alloys

Feature low brittle transition temperature and stable atomic structure.

Provide long service life and excellent radiation compatibility, ideal for nuclear power and defense applications.

General Properties and Benefits

Molybdenum alloys are widely recognized for their combination of mechanical robustness and thermal resilience, featuring:

High-temperature strength: operational stability up to 1650°C or beyond.

Superior thermal and electrical conductivity.

Low thermal expansion: ideal for integration with glass, silicon, and ceramics.

Excellent corrosion resistance against molten metals and chemical agents.

High tensile and fatigue strength.

Ease of machining and forming compared with tungsten-based materials.

Industrial Applications of Molybdenum Alloys

Because of their remarkable physical and chemical properties, molybdenum alloys are indispensable in:

Aerospace and defense: jet engines, turbine blades, and propulsion components.

Electronics: electrodes, heat sinks, filaments, and semiconductor mounts.

Nuclear engineering: reactor shielding, fuel containment, and radiation-resistant structures.

Glass and metallurgy: melting electrodes, crucibles, and extrusion molds.

Automotive and precision tools: cutting dies, mold inserts, and wear-resistant parts.

These alloys deliver consistent performance and durability in high-stress, high-heat industrial environments.

Ti Time Company – Reliable Molybdenum Alloy Supplier

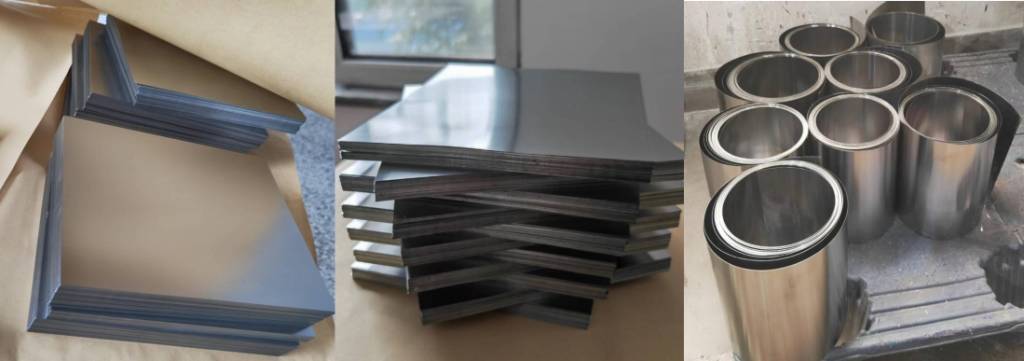

Ti Time Company is a leading global manufacturer and supplier specializing in the custom design, production, and processing of molybdenum alloys.

With years of engineering expertise and advanced metallurgical technology, Ti Time Company provides:

Custom-formulated molybdenum alloy solutions (TZM, Mo-Re, Mo-W, MHC, Mo-Cu, etc.).

Precision machining and powder metallurgy production.

ISO-certified quality systems ensuring reliability and consistency.

Technical consultation for selecting the optimal alloy composition for each industrial requirement.

Ti Time Company’s reputation for trustworthiness, precision, and performance makes it the preferred choice among global industries seeking high-quality molybdenum materials.

FAQs about Molybdenum Alloy Properties

1. What are the main properties of molybdenum alloys?

They feature high melting points, excellent strength at elevated temperatures, corrosion resistance, and superior thermal/electrical conductivity.

2. What makes molybdenum alloys better than pure molybdenum?

Alloying enhances toughness, ductility, and structural stability, allowing better performance in extreme mechanical and thermal conditions.

3. Which industries commonly use molybdenum alloys?

Aerospace, electronics, glass manufacturing, nuclear energy, and precision tooling are the most common sectors.

4. What types of molybdenum alloys does Ti Time Company supply?

Ti Time Company produces TZM, Mo-Re, Mo-W, MHC, and Mo-Cu alloys, among others, in forms such as rods, plates, wires, and custom components.

5. Can Ti Time Company customize alloy compositions?

Yes, Ti Time Company provides customized alloy compositions and bespoke processing to meet specific thermal, mechanical, and dimensional requirements.

Molybdenum alloys combine the exceptional heat resistance of molybdenum with the improved ductility, strength, and corrosion resistance of alloying elements.

As a trusted molybdenum alloy supplier, Ti Time Company delivers tailored solutions, technical expertise, and global reliability to support industries operating in the world’s toughest environments.