Why Choose Molybdenum Alloys?

Molybdenum alloys are known for their exceptional thermal strength, low thermal expansion, and resistance to high-temperature deformation and oxidation, making them critical for aerospace, electronics, nuclear, and industrial furnace applications.

Ti Time’s Featured Molybdenum Alloys

1. TZM Alloy (Titanium-Zirconium-Molybdenum)

Composition: ~0.5% Ti, 0.08% Zr, ~90% Mo

Applications: Aerospace engine parts, hot runner systems, extrusion dies

Advantages: Excellent creep resistance, superior load-bearing at high temperatures (~1900°C)

2. Mo-Re Alloy (Molybdenum-Rhenium)

Applications: Rocket nozzles, turbine blades, nuclear fuel cladding

Advantages: High ductility and radiation resistance; operates at ultra-high temperatures

Note: Ideal for extreme aerospace/nuclear demands

3. Mo-W Alloy (Molybdenum-Tungsten)

Applications: Tooling components, high-temp furnace parts

Advantages: Increased wear resistance, superior heat tolerance

4. Mo-Cu Alloy (Molybdenum-Copper)

Applications: Heat sinks, power semiconductors, thermal management

Advantages: High electrical/thermal conductivity with stable mechanical performance

5. MHC Alloy (Molybdenum-Hafnium-Carbon)

Applications: Spacecraft components, high-vacuum furnaces

Advantages: Extreme thermal stability and oxidation resistance

Why Ti Time Company?

🏭 In-House Production: From powder metallurgy to forging and rolling, we control every step.

🧪 Material Expertise: Our team includes engineers with deep experience in refractory alloy design and customization.

📦 Global Supply Chain: We support both bulk industrial orders and prototype production, offering flexible MOQs.

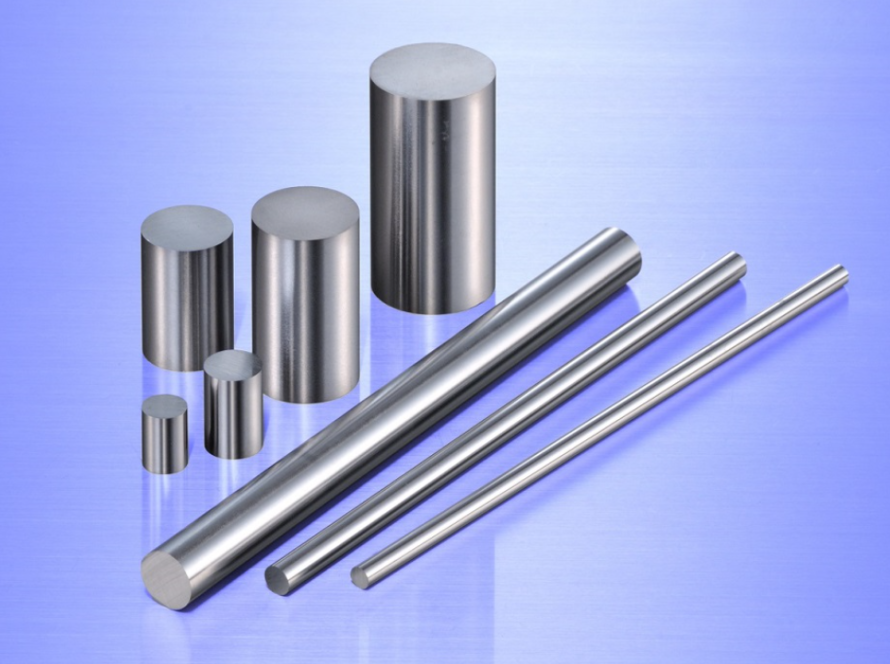

🔩 Precision Fabrication: Our molybdenum alloys can be delivered in rods, bars, plates, foils, crucibles, or as near-net shapes per drawing.

Frequently Asked Questions (FAQs)

What purity levels are available in your molybdenum alloy materials?

We offer ≥99.95% molybdenum base purity, with strict control over trace elements and alloying ratios.

Can Ti Time provide customized molybdenum alloy components?

Absolutely. We specialize in custom sizes, shapes, and alloy combinations tailored to your industrial specifications.

Are Ti Time’s molybdenum alloys suitable for vacuum and high-temperature use?

Yes. Our alloys are vacuum compatible, oxidation-resistant (when properly coated), and reliable in temperatures exceeding 1800°C.

What industries does Ti Time serve?

We work with aerospace, defense, semiconductors, nuclear energy, and high-temperature manufacturing sectors.

Do your molybdenum alloys meet international standards?

Yes. All products meet or exceed ASTM B387, ISO 9001, and customer-specific certifications.