Overview of Molybdenum Alloys

Molybdenum alloys are advanced materials composed mainly of molybdenum (Mo) combined with elements such as titanium, zirconium, rhenium, tungsten, hafnium, and carbon. These alloying additions are engineered to significantly enhance molybdenum’s mechanical, thermal, and chemical properties—especially under extreme temperatures and corrosive environments.

With a melting point exceeding 2600°C, molybdenum-based alloys provide a unique combination of strength, stability, and thermal conductivity, making them indispensable in aerospace, nuclear energy, and high-temperature industrial processes.

Common Types of Molybdenum Alloys and Their Properties

1. Molybdenum Rhenium (Mo-Re) Alloy

Contains 11–50% rhenium, which improves ductility, weldability, and resistance to brittle fracture.

Excellent creep strength and stability at elevated temperatures.

Applications: rocket nozzles, turbine blades, thermocouples, and nuclear reactor components.

2. Titanium Zirconium Molybdenum (TZM) Alloy

Composed of molybdenum with 0.5% titanium, 0.08% zirconium, and 0.02% carbon.

Features high tensile strength, corrosion resistance, and low thermal expansion.

Widely used in aerospace engines, high-temperature dies, and glass melting electrodes.

3. Molybdenum Copper (Mo-Cu) Alloy

Combines molybdenum’s mechanical strength with copper’s thermal and electrical conductivity.

Ideal for heat sinks, electrical contacts, and thermal management in power electronics.

4. Molybdenum Tungsten (Mo-W) Alloy

Integrates tungsten’s hardness with molybdenum’s machinability and lower density.

Common in cutting tools, furnace parts, and structural components exposed to high temperatures.

5. Molybdenum Hafnium Carbon (MHC) Alloy

Offers superior creep resistance and high-temperature strength, making it suitable for aerospace propulsion and nuclear technology.

Advantages of Molybdenum Alloys

High-temperature performance (usable up to 1650°C and beyond).

Excellent thermal and electrical conductivity.

Corrosion resistance against molten metals and glass.

Low coefficient of thermal expansion — compatible with glass, silicon, and ceramics.

High tensile and fatigue strength with low creep deformation.

Better processability compared with pure tungsten alloys.

These combined properties make molybdenum alloys highly valuable for extreme service environments.

Applications of Molybdenum Alloys

Molybdenum alloys play a vital role in numerous industries:

Aerospace: jet engine parts, turbine blades, and rocket components.

Electronics: electrodes, semiconductors, and heat sinks.

Nuclear energy: reactor components and radiation shields.

Glass and metallurgy: melting electrodes and extrusion dies.

Automotive and tooling: high-speed cutting tools, dies, and precision molds.

Their durability, conductivity, and stability under harsh conditions ensure longevity and performance in critical systems.

Ti Time Company — Trusted Molybdenum Alloys Supplier

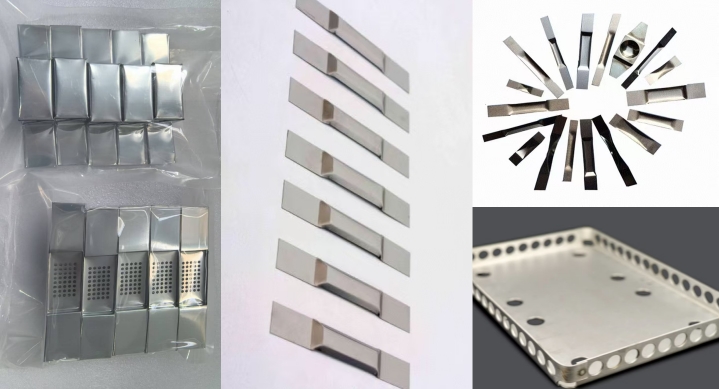

Ti Time Company is a leading manufacturer and supplier specializing in customized molybdenum alloys for industrial, aerospace, and electronic applications.

With years of experience, strong technical expertise, and ISO-certified manufacturing, Ti Time Company provides:

Custom alloy formulations (TZM, Mo-Re, Mo-W, Mo-Cu, MHC, and more).

Precision machining and powder metallurgy production.

Consistent quality control and global delivery.

Technical consultation for alloy selection and design optimization.

Ti Time Company’s professional approach ensures clients receive reliable materials that meet the highest engineering standards.

FAQs about Molybdenum Alloys

1. What are molybdenum alloys used for?

They are used in aerospace, electronics, glass manufacturing, and nuclear industries for parts that require strength, heat resistance, and conductivity.

2. How does adding rhenium or titanium improve molybdenum?

Rhenium enhances ductility and weldability; titanium and zirconium increase strength, creep resistance, and structural stability.

3. What is the difference between pure molybdenum and TZM alloy?

Pure molybdenum is strong but brittle; TZM adds titanium, zirconium, and carbon to significantly increase toughness and durability at high temperatures.

4. Does Ti Time Company offer customized molybdenum alloys?

Yes, Ti Time Company manufactures tailor-made molybdenum alloy products based on specific mechanical, thermal, and dimensional requirements.

5. Why choose Ti Time Company as your molybdenum alloy supplier?

Because of its decades of experience, cutting-edge production technology, strict quality standards, and global delivery reliability.

Molybdenum alloys represent the pinnacle of high-performance materials, balancing heat resistance, strength, and conductivity for advanced engineering challenges.

As an experienced molybdenum alloys supplier, Ti Time Company combines scientific expertise, precision manufacturing, and trustworthy service to deliver world-class solutions for global industries.