At Ti Time Company, we specialize in the custom manufacturing and supply of molybdenum-based materials and components, ensuring top performance across demanding industries worldwide.

What Is Molybdenum Used For?

1. Steel and Alloy Production

Around 80–86% of all molybdenum is used in the steel industry. When alloyed with steel, molybdenum increases strength, hardness, and heat resistance, allowing products to perform under extreme environments.

Applications include:

Structural and stainless steel

Automotive components (engine parts, exhaust systems)

Aerospace and turbine blades

High-performance tools and superalloys

Ti Time Company provides custom molybdenum alloy materials with precise chemical composition and machining options to meet client specifications.

2. Catalysts and Chemical Industry

Molybdenum compounds serve as key catalysts in petroleum refining and chemical synthesis, particularly for removing sulfur and nitrogen impurities.

They are also used in flame retardants, corrosion inhibitors, and smoke suppressants for plastics and organic materials.

Our high-purity molybdenum oxide and catalyst-grade powders ensure consistent reaction performance in industrial processes.

3. Lubricants and Friction Control

Molybdenum disulfide (MoS₂) is one of the most well-known solid lubricants.

It provides low friction under high pressure and temperature, making it ideal for:

Automotive engines

Industrial bearings and gears

Aerospace components

Ti Time Company supplies MoS₂ powders and coatings that ensure durability and long service life under extreme conditions.

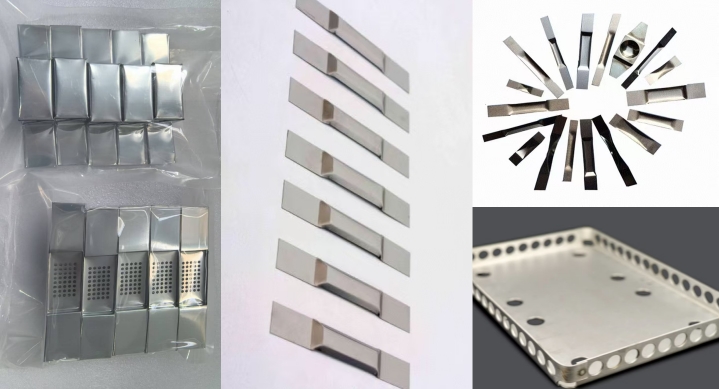

4. Electronics and Semiconductor Applications

Molybdenum’s high conductivity and stability make it vital in electronics manufacturing, including:

Thin-film transistors (TFTs)

Flat-panel displays

Electrical contacts and semiconductors

Ti Time Company’s molybdenum sheets, rods, and targets meet strict purity and dimensional standards, suitable for precision electronics fabrication.

5. Medical and High-Temperature Applications

Due to its biocompatibility and strength, molybdenum is widely used in:

Orthopedic implants

X-ray tube components

Heating elements and furnace parts

Our molybdenum bars and wires are crafted to deliver stable performance even in high-vacuum and thermal processing environments.

Why Choose Ti Time Company as Your Molybdenum Supplier?

✅ Experience (E): Over 15 years in refractory metal production and international trade.

✅ Expertise (E): Advanced R&D and customized molybdenum material processing.

✅ Authoritativeness (A): Certified production with strict ISO quality systems.

✅ Trustworthiness (T): Global clients in aerospace, electronics, and chemical sectors rely on Ti Time for precision and consistency.

Ti Time Company doesn’t just supply molybdenum products — we engineer tailored solutions to meet your unique industrial requirements.

FAQs About Molybdenum Uses

1. What are the main industrial applications of molybdenum?

Molybdenum is primarily used in alloy steel, chemical catalysts, lubricants, and high-temperature applications due to its strength and corrosion resistance.

2. Why is molybdenum added to steel?

It enhances the metal’s hardness, tensile strength, and resistance to heat and corrosion, making it suitable for aerospace, automotive, and construction industries.

3. How does Ti Time Company ensure molybdenum product quality?

All products undergo chemical analysis, density testing, and microstructure inspection to meet international ASTM and GB standards.

4. Can Ti Time Company provide customized molybdenum parts?

Yes. We offer custom sizes, machining, and surface treatments to match client drawings and application requirements.

5. What are the benefits of molybdenum compared to tungsten?

Molybdenum is lighter and offers excellent thermal conductivity, making it ideal for electronics and thin-film applications, while tungsten suits ultra-high-temperature environments.

From heavy industry to advanced technology, molybdenum continues to be a metal of the future.

With Ti Time Company’s experience and manufacturing capability, clients gain access to high-purity, precisely engineered molybdenum products — empowering innovation in every sector.