Why Niobium Crucibles Are Preferred

Niobium crucibles are containers made from high-purity niobium metal, known for its:

🔥 Extreme Heat Resistance: With a melting point of 2468°C, niobium can endure high-temperature melting, vapor deposition, and synthesis processes.

🧪 Excellent Corrosion Resistance: Its stable oxide layer protects against acids, alkalis, and molten metals, minimizing contamination.

⚙️ High Mechanical Strength: Even under thermal stress, niobium crucibles retain shape and durability.

🔬 Purity Preservation: Ideal for melting reactive or high-purity materials such as titanium, zirconium, and rare earth metals.

✅ Biocompatibility: Suitable for use in applications involving pharmaceuticals or medical-grade materials.

Industries Served

Semiconductor & Electronics: For PVD/CVD coating processes and high-vacuum material fabrication.

Metallurgy: Melting and casting of ultra-pure alloys and reactive metals.

Synthetic Diamond Production: As a stable crucible material in high-pressure, high-temperature (HPHT) synthesis.

Chemical Processing: Ideal for corrosive substance containment under heat.

Aerospace & Nuclear: Components requiring structural integrity, neutron absorption resistance, and longevity.

FAQs – Niobium Crucibles by Ti Time Company

What is the purity level of your niobium crucibles?

We offer niobium crucibles in 99.5%, 99.9%, and 99.95% purity grades, depending on your specific application needs.

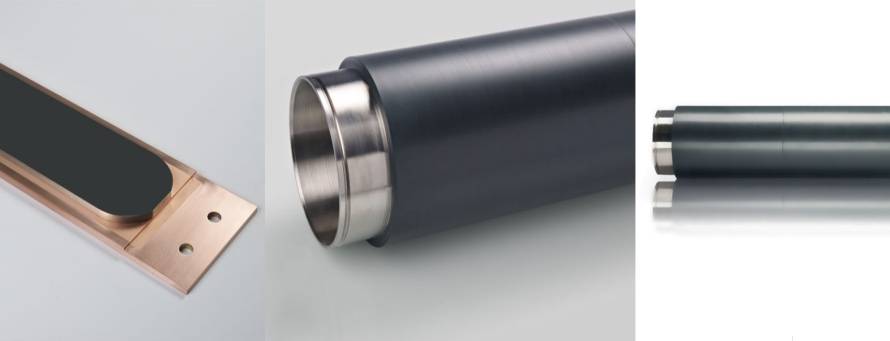

Can you customize niobium crucibles to specific shapes and dimensions?

Yes. We provide full OEM/ODM customization, including diameter, wall thickness, depth, and design (e.g., cylindrical, conical, round-bottomed).

What manufacturing processes are used?

We use welding, forging, stamping, and CNC machining to ensure structural integrity and dimensional accuracy.

Are these crucibles suitable for ultra-high vacuum or inert environments?

Absolutely. Our crucibles are regularly used in UHV and inert gas atmospheres like argon for PVD, CVD, and smelting.

What is the typical delivery time for custom orders?

Standard delivery is 2–3 weeks. Rush orders are available upon request for critical R&D or production timelines.