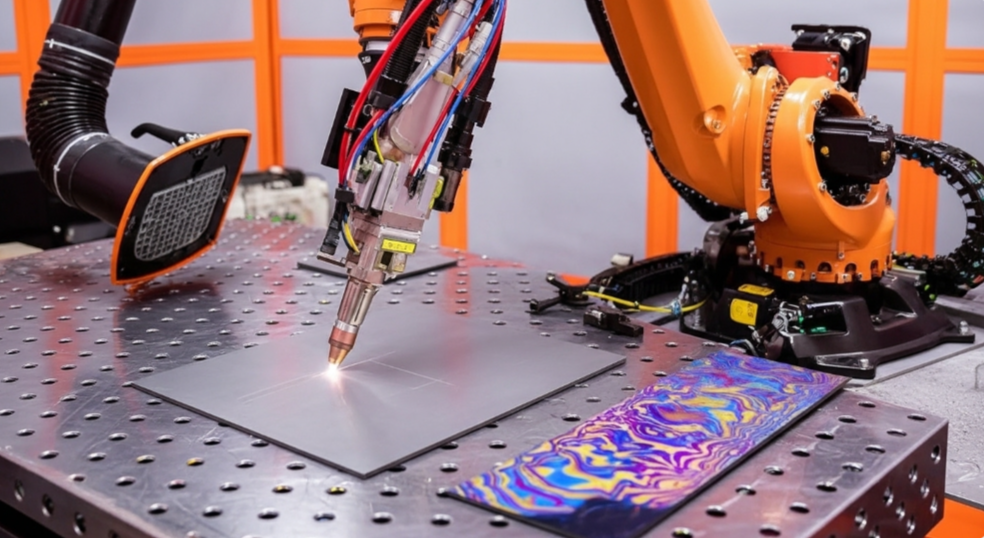

In the world of advanced metallurgy, plasma cutting titanium is a specialized process that requires a delicate balance of speed, temperature control, and gas shielding. Unlike cutting mild steel, titanium’s high reactivity at elevated temperatures means that the cutting process can fundamentally alter the metal’s chemistry.

As a premier plasma cutting titanium supplier, Ti Time Company leverages decades of expertise to provide high-quality titanium materials and customized manufacturing services. Whether you are roughing out heavy aerospace blanks or looking for precision machined titanium parts, our ISO9001-certified facilities ensure that every cut meets the highest international standards, including ASTM, AMS, and MIL-spec.

II. Why Choose Plasma Cutting for Titanium?

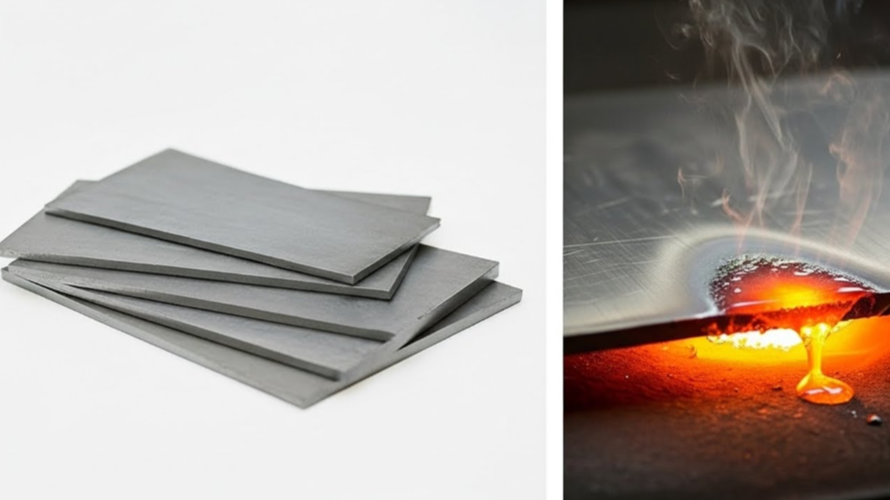

Plasma cutting titanium is an efficient choice for primary processing, especially when working with thicker plates where mechanical sawing would be too slow.

Speed and Efficiency: For bulk industrial applications, plasma is significantly faster than traditional mechanical cutting.

Cost-Effectiveness: It offers a lower tooling cost compared to waterjet or laser cutting for non-critical, thicker sections.

Conductivity Advantage: Because titanium is highly conductive, it responds exceptionally well to the high-temperature plasma jet.

However, because titanium is sensitive to oxygen, the process often results in a Heat-Affected Zone (HAZ). At Ti Time Company, we specialize in the secondary customized production of these parts, ensuring that any oxidized layers are professionally machined away to restore the metal’s integrity.

III. Key Technical Challenges and Solutions

To achieve a professional-grade finish during plasma cutting titanium, several technical factors must be addressed:

Oxidation Management: Titanium readily absorbs oxygen and nitrogen at high temperatures, which can lead to embrittlement. We recommend using Argon or Nitrogen-based gas mixes to shield the cut.

Parameter Tuning: Titanium melts faster than steel. A common expert tip is to increase travel speed by roughly 20% compared to aluminum settings to prevent overheating.

Post-Process Machining: Since plasma leaves a hardened “alpha case” on the edge, precision components must be ground or milled. As a leading machined titanium supplier, we provide full-service finishing to ensure your parts are ready for high-stress environments like medical or aerospace use.

IV. FAQ: Expert Insights on Plasma Cutting Titanium

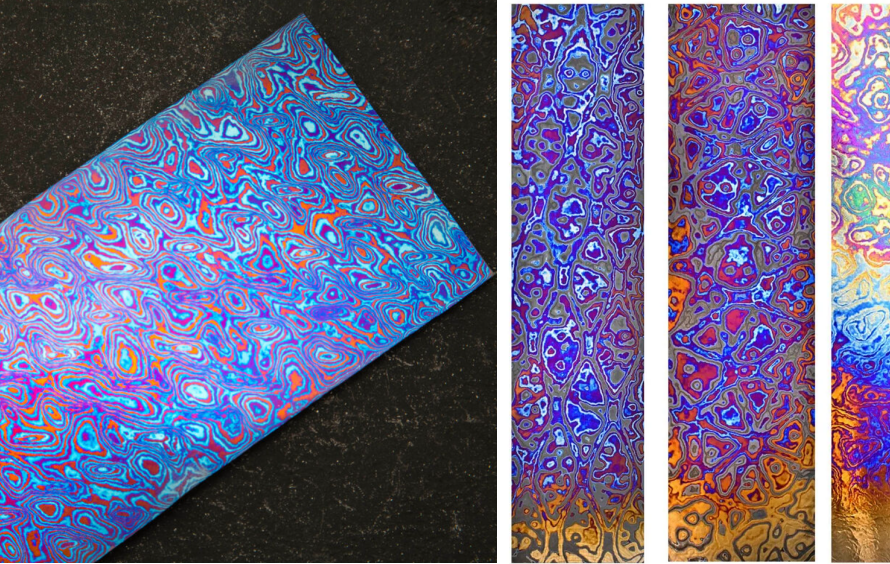

Q1: What does a “bad” plasma cut look like on titanium? A: If you see a bright blue, violet, or white flaky oxide on the edge, the metal has been heavily oxidized. A high-quality cut should ideally be a silver or light straw color, indicating minimal oxygen absorption.

Q2: Can I use standard shop air for plasma cutting titanium? A: While shop air (oxygen/nitrogen mix) will cut the metal, it will cause significant oxidation. For industrial or “clean” results, high-purity inert gases are required to protect the kerf.

Q3: Is the Heat-Affected Zone (HAZ) a deal-breaker for aerospace parts? A: In its raw state, yes. However, if the plasma cut is used as a “rough-in” and the final dimensions are achieved through CNC machining to remove at least 1-2mm of the edge, it is a perfectly acceptable industrial practice.

Q4: Does Ti Time Company provide custom-cut titanium blanks? A: Yes. We offer customized production of titanium plates, rods, and targets. We can plasma-cut your requested shapes and then utilize our in-house milling to provide a finished, “spec-ready” component.

Q5: What safety precautions are unique to titanium cutting? A: Titanium dust and fines are highly flammable. It is vital to maintain a clean workspace and use specialized fume extraction, as titanium oxide fumes are hazardous if inhaled.

V. Ti Time Company: Your Trusted Global Partner

Ti Time Company is more than just a plasma cutting titanium supplier. We are a comprehensive manufacturer of advanced materials, including titanium sputtering targets, tungsten, molybdenum, and complex alloys.

From customized manufacturing of capillary tubes to large-scale forgings, our products are exported to the US, Japan, and Germany, serving the world’s most demanding industries. Our commitment to the ISO9001 quality system ensures that your materials are reliable, traceable, and performed to perfection.