Platinum Coated Titanium Electrodes: The Ultimate Guide to High-Performance Anodes

In the world of electrochemistry, efficiency and durability are the benchmarks of success. Platinum coated titanium electrodes (often called platinized titanium anodes) have become the industry standard for demanding environments. By marrying the catalytic brilliance of platinum with the rugged mechanical strength of titanium, these electrodes offer a “non-consumable” solution for high-current applications.

As a leading platinum coated titanium electrodes supplier, Ti Time Company specializes in the custom manufacturing of high-performance electrodes designed to meet the rigorous needs of global industrial and laboratory clients.

I. Understanding the Structure: Titanium Core meets Platinum Surface

A platinum coated titanium electrode is a composite material where a thin layer of pure platinum is deposited onto a titanium substrate.

The Titanium Substrate: Acts as a lightweight, high-strength “backbone.” Titanium is naturally corrosion-resistant due to a self-healing oxide layer, ensuring the electrode maintains its shape even under mechanical stress.

The Platinum Coating: Typically ranges from 0.5µm to 20µm. Platinum provides exceptional electrical conductivity and a low overpotential for critical reactions like oxygen and chlorine evolution.

The Bonding Process: At Ti Time Company, we utilize advanced electroplating and thermal decomposition techniques to ensure maximum adhesion. Our coatings are designed to resist peeling and dissolution even at current densities up to 75 A/dm².

II. Key Advantages of Platinized Titanium Anodes

Why choose platinized titanium over traditional graphite or lead anodes?

Exceptional Dimensional Stability: Unlike lead, which erodes and changes shape, Ti Time’s electrodes remain geometrically constant, ensuring a uniform current distribution throughout the process life.

High Catalytic Activity: Lower overpotentials lead to significant energy savings and higher current efficiency.

Corrosion Resistance: Stable across a wide pH range (pH 1–12) and highly effective in saline environments like seawater.

Cost-Effectiveness: Using a thin platinum coating on titanium is far more economical than solid platinum while delivering identical electrochemical performance.

Maintenance Free: These are essentially non-consumable anodes, drastically reducing downtime and replacement costs.

III. Critical Applications

As a versatile supplier, Ti Time Company provides tailored solutions for:

Electroplating: Essential for precious metal plating (Gold, Platinum, Rhodium) and hard chrome plating (fluoride-free).

Water Treatment: Used in salt chlorinators for swimming pools, industrial wastewater oxidation, and ozone generation.

Hydrogen Production: Serving as high-efficiency anodes in PEM electrolyzers and alkaline water electrolysis.

Cathodic Protection (ICCP): Protecting pipelines, ship hulls, and offshore structures from corrosion in seawater and soil.

Electrodialysis: Durability in acid/alkali recovery and desalination systems.

IV. FAQ: Expert Insights from Ti Time Company

Q: What is the typical lifespan of a platinum coated titanium electrode? A: In standard conditions, our anodes can last between 5 to 10 years. Lifetime depends on the electrolyte composition, current density, and the thickness of the platinum layer. For example, in chromium plating, the consumption rate is often as low as 1–4 grams per million ampere-hours.

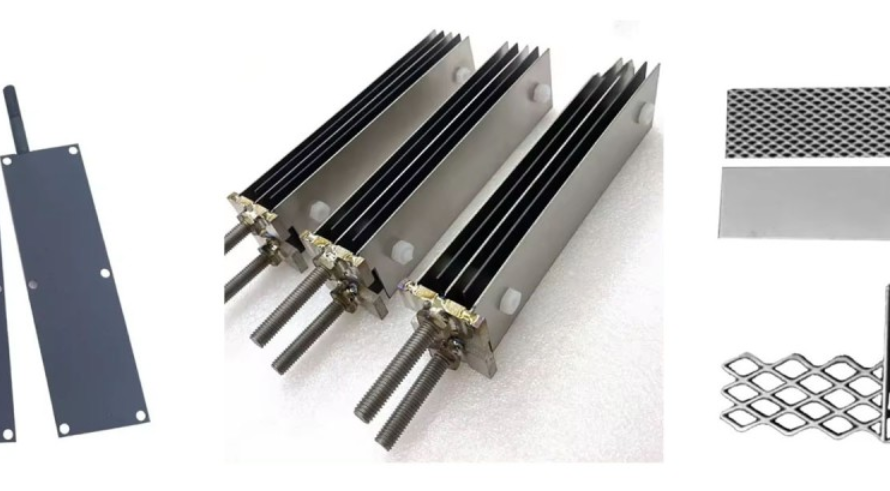

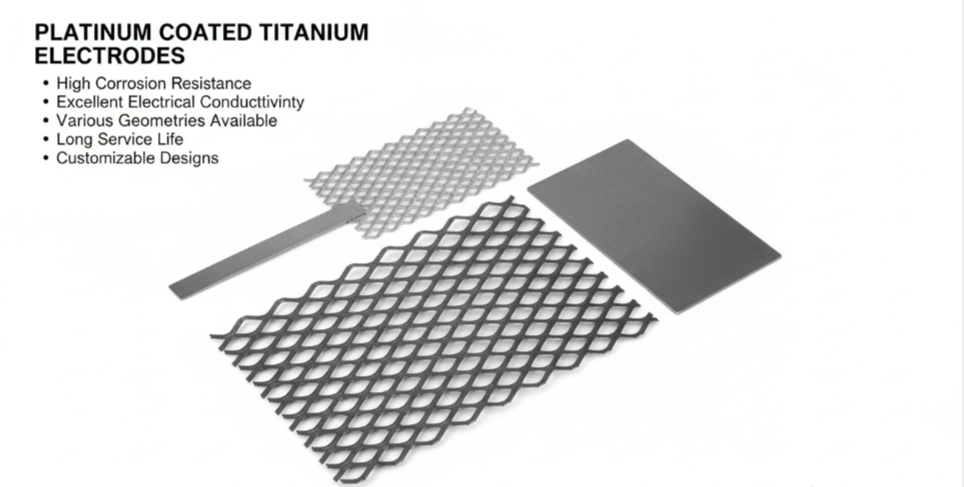

Q: Can I customize the shape and size of the electrode? A: Absolutely. Ti Time Company offers custom production for all varieties. We manufacture:

Titanium Mesh Anodes (highest surface area)

Titanium Plate/Sheet Anodes

Tubular and Rod Electrodes

Custom complex geometries for specialized reactor cells

Q: Are there any environments to avoid? A: While highly resistant, these electrodes should generally avoid electrolytes containing high levels of fluoride ions (>50 mg/L), as fluorides can attack the titanium substrate beneath the platinum coating.

V. Why Partner with Ti Time Company?

Choosing Ti Time Company means choosing a supplier with deep metallurgical expertise. We don’t just sell electrodes; we provide engineered solutions.

Customization: We meet any requirement for platinum loading (grams per square meter) and substrate geometry.

Reliability: Each batch undergoes rigorous testing for coating thickness and adhesion.

Experience: Our engineers help you optimize electrode selection to lower your total cost of ownership.