Description

High-Performance CrAl Sputtering Target for Hard Coatings, 99.8% Purity: The Ultimate Industrial Guide

I. Technical Specifications and Manufacturing Excellence

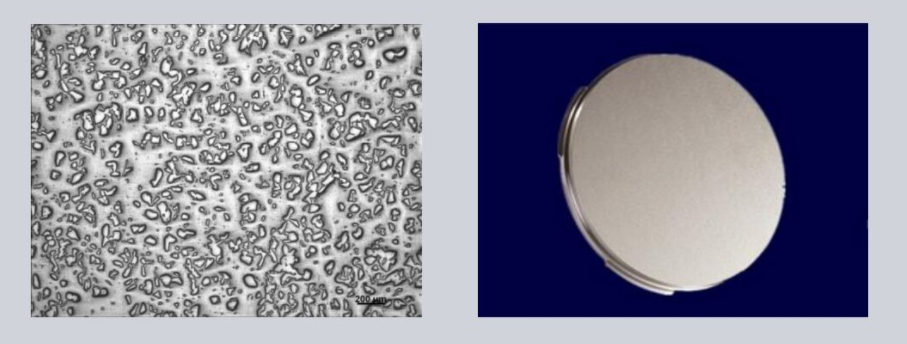

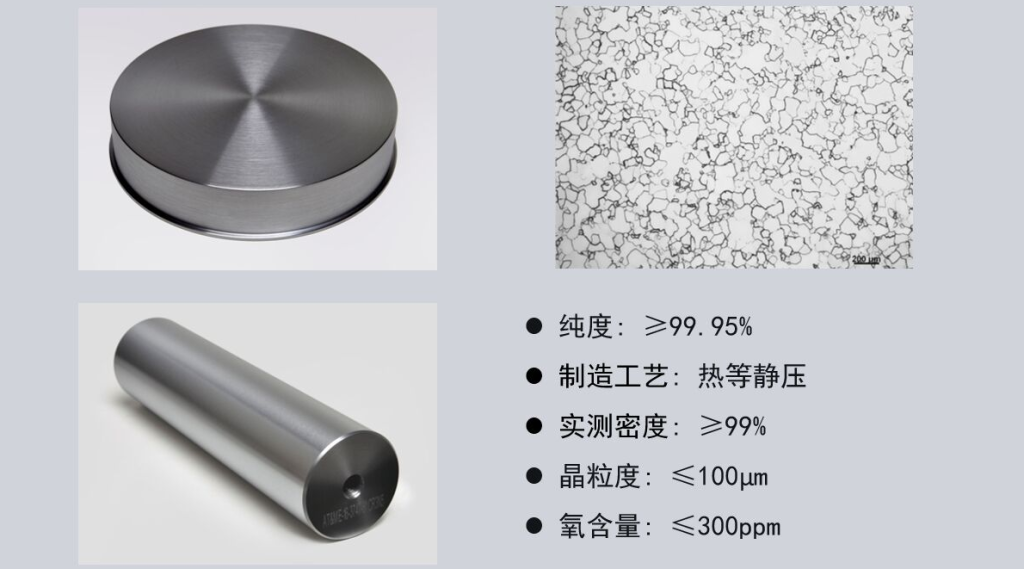

A superior CrAl Sputtering Target for Hard Coatings, 99.8% Purity is not merely a mixture of metals; it is a precisely engineered alloy. At Ti Time Company, we use the Hot Isostatic Pressing (HIP) process to consolidate Chromium and Aluminum powders, resulting in a target with near-theoretical density and ultra-fine grain structure.

Core Technical Profile:

Typical Stoichiometry: Cr-70at%Al (70% Aluminum atomic ratio).

Main Composition: Cr (45.2 ± 1) wt%.

Density: 3.76g/cm³ (High density prevents arcing during deposition).

Impurity Control: Strict limits on oxygen (< 2000 ppm), nitrogen (< 200 ppm), and iron (< 700 ppm) to ensure coating toughness.

II. Why Choose CrAl for Hard Coatings?

Using a CrAl Sputtering Target for Hard Coatings, 99.8% Purity allows manufacturers to create films that outperform traditional CrN or TiN coatings in several ways:

Exceptional Oxidation Resistance: The addition of Aluminum promotes the formation of a stable, protective Al₂O₃ oxide layer on the coating surface at high temperatures.

High Red Hardness: CrAlN coatings maintain their hardness even when the cutting tool reaches high temperatures during dry machining.

Superior Adhesion: Chromium-based nitrides are famous for their strong chemical bond to steel and carbide substrates, drastically reducing the risk of delamination under heavy loads.

III. Applications in High-Demand Industries

As a trusted supplier, Ti Time Company provides customized production of CrAl targets for various high-stress scenarios:

Precision Tooling: Enhancing the service life of drills, end mills, and taps used in high-speed machining.

Molding & Die Casting: Protecting injection molds and punching dies from wear and corrosion.

Automotive Components: Applying durable, low-friction coatings to engine parts and decorative trim.

IV. FAQ: Expert Insights on CrAl Sputtering Targets

Q1: Why is the 99.8% purity level significant for hard coatings? A: While semiconductor targets require higher purity, 99.8% purity is the industrial “gold standard” for hard coatings. It provides the necessary mechanical toughness while keeping the sputtering target price viable for high-volume tool production.

Q2: How does the Cr:Al ratio affect the coating performance? A: A higher Aluminum content (like our Cr-70at%Al) generally improves oxidation resistance and hardness. However, we offer customized manufacturing for different ratios (e.g., 50:50 or 60:40) depending on whether the user prioritizes toughness or thermal stability.

Q3: Is DC magnetron sputtering suitable for CrAl targets? A: Yes. Because CrAl alloys are electrically conductive, they are perfectly suited for DC or pulsed DC magnetron sputtering. This allows for high deposition rates and excellent film density.

Q4: What are the typical impurity limits for a high-quality CrAl target? A: For a reliable CrAl Sputtering Target for Hard Coatings, 99.8% Purity, impurities like Iron (Fe) should be <700 ppm and Silicon (Si) <500 ppm. High oxygen or carbon content can lead to brittle coatings that fail prematurely.

Q5: Can Ti Time Company produce rotary CrAl targets? A: Absolutely. We provide both planar and rotary (tubular) configurations. Rotary targets are highly recommended for large-scale industrial coating lines due to their higher material utilization and longer campaign times.

V. Ti Time Company: Your Trusted Global Partner

Ti Time Company is a leading manufacturer and supplier specializing in titanium, chromium, tungsten, molybdenum, and composite materials. With decades of experience, we are known for delivering high-quality products and exceptional customer service.

Our offerings include plates, rods, tubes, and specialized sputtering targets. Operating under the ISO9001 quality system, our products meet ASTM, ASME, AMS, and MIL standards, and are exported to the US, Japan, Germany, and South Korea. Whether you need a titanium sputtering target or a high-density CrAl Sputtering Target for Hard Coatings, 99.8% Purity, we are your partner in precision.

Reviews

There are no reviews yet.