Description

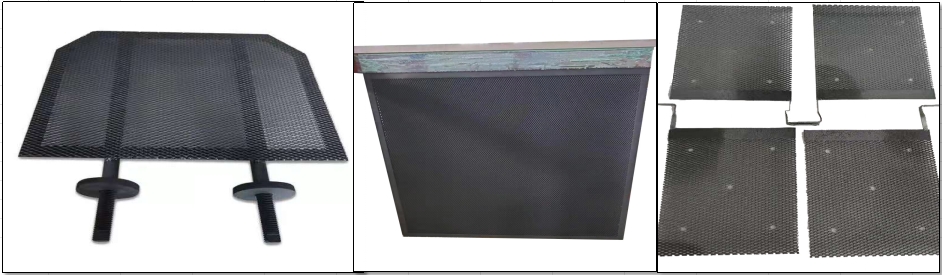

Noble Metal Oxide Titanium Electrodes

Chlorine Generating Electrode Series

Types:

- Chlorine Generating Electrode

- Ru-Ir Titanium Electrode

Specifications

- Base Material: Pure Titanium

- Shapes Available:

- Plates

- Meshes

- Wires

- Rods

- Multi-Hole Titanium

- Tubes

- Current Density:

- Maximum: <3200 A/m²

- Common Use: <1500 A/m²

- Manufacturing Process: Sintering

- Coating Materials: Ruthenium (Ru), Iridium (Ir), Titanium (Ti), etc.

- Precious Metal Content: 5-20 g/m²

- Coating Thickness: 4-15 μm

- Weight Loss During Strengthening: ≤10 mg

- Polarization Rate: ≤40 mV

- Service Life:

- Electrolyte: 0.5 mol/L Sulfuric Acid

- Duration: ≥20 hours

- Chlorine Evolution Potential: ≤1.13 V (Saturated Calomel Electrode)

- Oxygen Evolution Potential: ≤1.00 V (Mercury Sulfide Electrode)

- Chlorine Efficiency:

- ≥85% in 3.5% NaCl solution at 15°C

- ≥60% in 3.5% NaCl solution at 5°C

Applications of Ru-Ir Titanium Electrodes

- Chlor-alkali Industry

- Chlorate Production

- Hypochlorite Production

- Perchlorate Production

- Seawater Electrolysis

- Chlorine Dioxide Production

- Drinking Water Treatment

- Industrial Water Treatment

- Power Plant Cooling Water Treatment

- Electrolytic Extraction of Non-Ferrous Metals

- Cathodic Protection for Ships

- Seawater Desalination

Titanium Electrodes for Sodium Hypochlorite Generators

1. Electrode Working Principle:

- Reactions in the Electrolytic Cell:

- Overall Reaction: NaCl + H₂O → NaOH + Cl₂ + H₂↑

- Anode Reaction: 2NaCl → 2Na⁺ + Cl₂ + 2e⁻

- Cathode Reaction: 2H₂O + 2e⁻ → H₂↑ + 2OH⁻

2. Technical Parameters:

- Water Temperature: ≤60°C

- Current Density: ≤1500 A/m²

- Service Life: ≥250 hours

- Chlorine Evolution Potential: ≤1.13 V

- Current Efficiency:

- Warm Water (15°C): ≥85%

- Cold Water (5°C): ≥65%

Noble Metal Oxide Titanium Electrodes

Types:

- Oxygen Generating Electrode

- Iridium-Tantalum Titanium Electrode

Specifications

- Base Material: Pure Titanium

- Available Shapes: Plates, Meshes, Wires, Rods, Multi-Hole Titanium, Tubes

- Current Density: <8000 A/m²

- Manufacturing: Sintering

- Coating Materials: Iridium (Ir), Tantalum (Ta), etc.

- Precious Metal Content: 2-25 g/m²

- Coating Thickness: 1-15 μm

- Service Life:

- Electrolyte: 1.0 mol/L Sulfuric Acid

- Duration: ≥20 hours

- Oxygen Evolution Potential: ≤1.00 V (Mercury Sulfide Electrode)

Quality and Innovation

With 15 years of expertise, Titime collaborates with top experts to enhance electrode performance, ensuring cutting-edge and efficient technologies.

Applications

- Chemical Recovery: Convert sodium sulfate to sulfuric acid and caustic soda

- Cathodic Protection

- Water Electrolysis

- Extraction of Non-Ferrous Metals

- Copper Foil Manufacturing

- Aluminum Foil Anodes

- Tin Plating on Steel

- Organic Electrolysis

Why Choose Our Electrodes

- High Performance: Durable in harsh conditions and high temperatures

- Long-Lasting Coatings: High precious metal content for efficiency and longevity

- Versatile Use: Suitable for various industries like metallurgy and water treatment

- Quality Assurance: Advanced sintering ensures consistent quality

- Customizable: Available in multiple shapes and specifications

Titanium Electrodes for Electrolytic Copper Foil

Key Features

- Highly Stable: Extremely corrosion-resistant, suitable for various environments.

- High Overpotential for Oxygen Evolution: Efficient for oxygen-generating reactions.

- Low Overpotential for Hydrogen Evolution: Efficient for hydrogen-generating reactions.

Specifications

- Base Material: Pure Titanium

- Available Shapes: Plates, Meshes, Wires, Rods, Tubes, Multi-Hole Titanium, Titanium Felt, etc.

- Current Density: <1000 A/m²

- Manufacturing Process: Sintering/Electroplating

- Coating Material: Platinum (Pt)

- Precious Metal Content: 21.75 g/m²

- Platinum Coating Thickness: 0.1-5 μm

Applications

- Organic Synthesis

- Cathodic Protection

- Perchlorate Production

- Seawater Electrolysis

- Water Electrolysis

- Hydrogen Peroxide Production

Why Choose Our Platinized Titanium Electrodes

- Durability: Resistant to corrosion and ideal for harsh chemical environments.

- Efficiency: Superior performance in both oxygen and hydrogen reactions.

- Versatility: Suitable for a wide range of industrial processes.

- Quality Assurance: Manufactured using advanced sintering and electroplating techniques to ensure consistent quality.

Lead Oxide Titanium Electrodes

Overview

Lead dioxide (PbO₂) titanium electrodes are highly conductive materials with metallic-like properties. They have been extensively used in the electrolysis industry due to their excellent performance characteristics.

Key Features

- Excellent Conductivity:

- Electrical resistance: 4×10⁻⁵ to 5×10⁻⁵ Ω·cm.

- Superior Anode Performance:

- High oxygen evolution potential.

- Strong oxidizing ability.

- High corrosion resistance.

- Good electrical conductivity.

- High current density.

- Enhanced Stability:

- Advanced multi-layer (base, intermediate, surface) coating process.

- Prevents traditional issues like cracking, peeling, and passivation.

- Improved durability and performance.

Specifications

- Base Material: Pure Titanium

- Coating Material: Lead Dioxide (PbO₂)

- Coating Thickness: Varies based on application requirements

- Electrical Resistance: 4×10⁻⁵ to 5×10⁻⁵ Ω·cm

- Current Density: High, suitable for demanding electrolysis processes

Applications

- Electrolysis:

- Used in various electrochemical processes requiring efficient oxygen evolution.

- Metallurgy:

- Essential for high-performance metallurgical applications.

- Other Industries:

- Suitable for any application requiring durable and highly conductive anode materials.

Advantages

- High Performance:

- Maintains integrity under extreme conditions.

- Durability:

- Enhanced resistance to wear and corrosion extends electrode lifespan.

- Efficiency:

- High conductivity and effective oxygen evolution improve overall process efficiency.

- Reliability:

- Consistent performance in demanding industrial environments.

Why Choose Our Lead Oxide Titanium Electrodes

- Innovative Design:

- Advanced multi-layer coating technology ensures superior stability and performance.

- Quality Assurance:

- Manufactured under strict quality controls to meet industry standards.

- Customization:

- Available in various sizes and specifications to suit specific application needs.

- Experienced Support:

- Backed by 15 years of expertise in electrode material development and supply.

Lead-titanium electrode technology research and development

Reviews

There are no reviews yet.