Description

Pure Hafnium Metal (Hf) and Hafnium Alloys

Overview

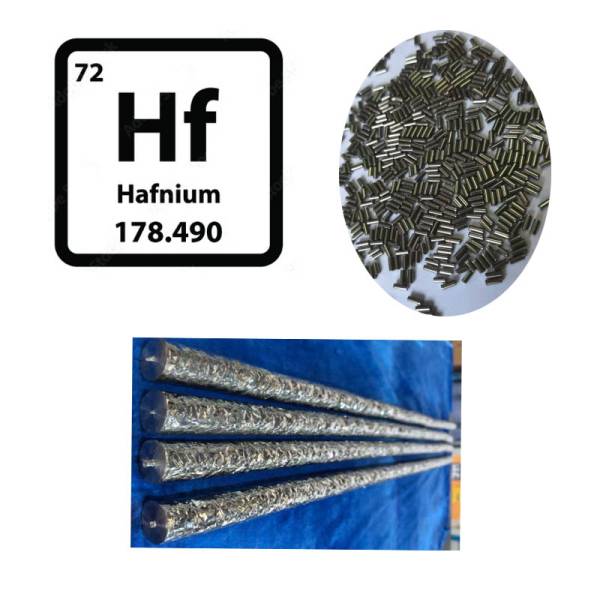

Hafnium (Hf) is a shiny, silvery metal known for its excellent corrosion resistance and high strength. Similar to zirconium, hafnium forms a tough, protective oxide layer that prevents corrosion, making it highly durable. It is resistant to most acids and bases except hydrofluoric acid. Due to its similar atomic size to zirconium, separating hafnium from zirconium is challenging.

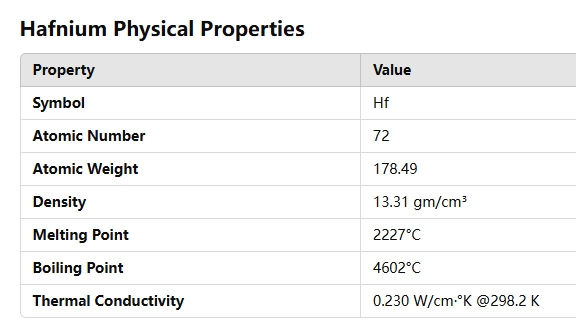

Properties

- Appearance: Shiny silvery metal

- Corrosion Resistance: Excellent, protected by a tough oxide layer

- Strength: High

- Melting Point: Very high; compounds are highly refractory

- Atomic Details:

- Symbol: Hf

- Atomic Number: 72

- Atomic Weight: 178.49

- Electron Configuration: [Xe] 4f¹⁴ 5d² 6s²

- Atomic Radius: 159 pm

- Van der Waals Radius: 212 pm

Applications

- Nuclear Industry:

- Control Rods: Used in nuclear reactors and submarines for excellent neutron absorption

- High-Temperature Alloys and Ceramics:

- Refractory Materials: Utilized in environments with extreme temperatures due to their high melting points

- Semiconductor Manufacturing:

- Components: Essential in creating high-temperature alloys and circuit components for semiconductor devices

- Chemical Processing:

- Corrosion-Resistant Equipment: Ideal for use in harsh chemical environments

History

Hafnium was predicted by Dmitri Mendeleev in 1869 but was first isolated by Dirk Coster and George de Hevesy in 1922. It does not occur naturally as a free element but is found in zirconium compounds like zircon.

Additional Information

Hafnium is named after “Hafnia,” the Latin name for Copenhagen, where it was discovered. Please note that all provided data is for reference only. Titime does not guarantee the accuracy of this information or its applications. Finished part drawings may be shared with third parties for outsourcing purposes.

Typical Applications

- Nuclear Reactors

- Material: Hafnium (Hf)

- Nuclear Submarines

- Purity: 99.5% Hafnium (2N5)

- Medical Equipment

- Purity: 99.9% Hafnium (3N)

- Fuel Cells

- Standards: ASTM B-776 R1 or R3 grade

- Solar Energy Systems

- Standards: ASTM B-737 R1 or R3 grade

- Commercial Welding Torches

Titime has performed well in the field of hafnium (Hf) related products and is a highly regarded supplier in the world. The hafnium products we supply cover multiple categories, including foils, strips, sheets, plates, discs, wires, rods (various specifications), billets, tubes (different types), accessories, crucibles, sputtering targets, as well as semi-finished and finished parts. We can also provide hafnium (Hf) products with customized sizes and customized grades according to customer needs.

Titime adheres to the concept of high quality. As an ISO-certified company, it has been committed to supplying high-quality hafnium products to customers around the world for the past 15 years. With our own advantages, we can not only ensure the high quality of our products, but also provide customers with hafnium products that meet their personalized needs at a very competitive price and with a short delivery time, fully meeting the needs of various application scenarios in the market.

Reviews

There are no reviews yet.