Description

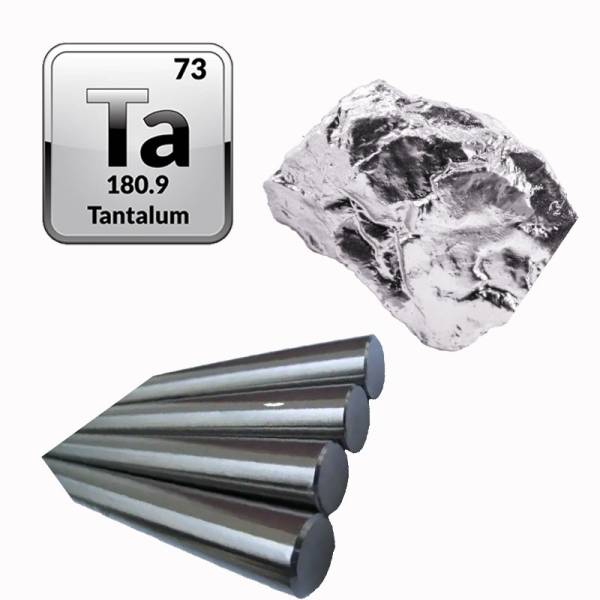

Tantalum (TA) and Tantalum Alloys

Introduction:

Tantalum is a rare, dense, and highly ductile metal with a deep blue-gray color. It is known for its exceptional corrosion resistance, especially to chemicals below 150°C, dissolving only in hydrofluoric acid. With a melting point of approximately 2,996°C, tantalum has the fourth highest melting point among metals, after tungsten and rhenium. Pure tantalum recrystallizes at around 2,200°F (1,204°C). Its primary applications include capacitors, vacuum furnaces, chemical process equipment, nuclear reactors, structural components, and aircraft parts.

Applications and Availability:

Eagle Alloys is a supplier of high-quality tantalum and tantalum alloys, serving a wide range of industries. The company offers tantalum in various forms, sizes, and quantities, both in its pure form and as alloys. Tantalum is a sought-after metal due to its critical role in modern technology. For example, it is often found in capacitors that power popular devices like smartphones, computers, and video game systems.

Key Features:

- Corrosion and Heat Resistance: Tantalum is highly resistant to corrosion and high temperatures.

- Biocompatibility: It is chemically inert and non-toxic, making it suitable for medical applications such as surgical tools and implants.

- Ductility: Tantalum is extremely malleable, easily forming into flexible wires.

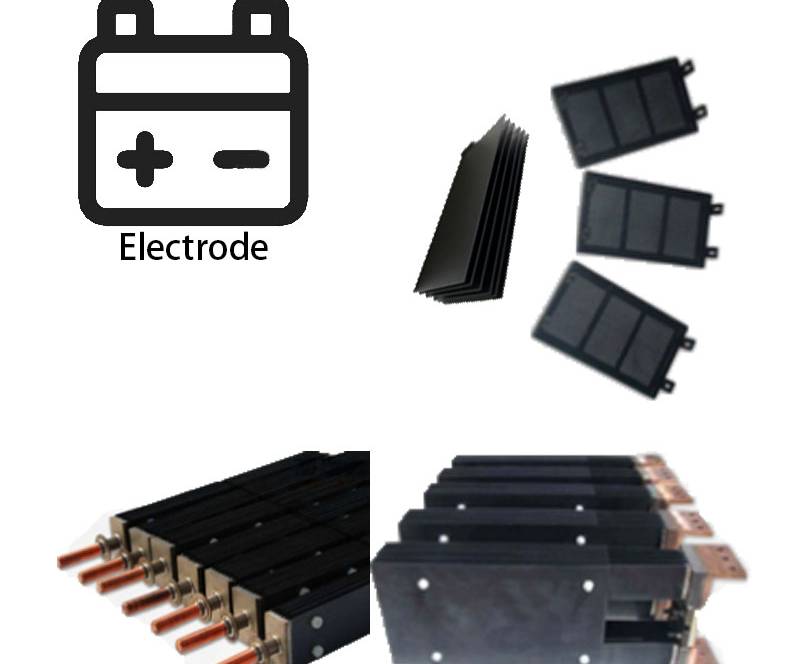

These unique properties make tantalum an ideal material for both pure and alloyed applications. Its resistance to deformation and corrosion also makes it suitable for use in medical implants. However, its most common use remains in capacitors for computer chips, critical to powering modern electronic devices.

For more details about tantalum processing, refer to our general guide on the subject.

Typical Applications of Tantalum (Ta)

- Electronics: Capacitors, semiconductors, sputtering targets, magnetic shielding

- Industrial Equipment: Vacuum furnaces, chemical processing equipment, heat exchangers, condensers

- Aerospace and Defense: Aircraft parts, ballistic components, valves, fasteners

- Medical and Dental: Surgical implants, closures, dental implants, orthopedic components

- Energy and Metallurgy: Nuclear reactors, crucibles, engine turbine blades

- Other: Mesh, screens, hard metal cutting tools, radiation shielding

Mechanical Properties of Tantalum

Annealed:

- Ultimate Tensile Strength: 285 MPa (41 KSI)

- Yield Strength: 170 MPa (25 KSI)

- Elongation: >30%

- Hardness: 90 HV

- Other: 80%+ reduction in area

Cold Worked:

- Ultimate Tensile Strength: 650 MPa (95 KSI)

- Elongation: ~5%

- Hardness: 210 HV

Mechanical Properties of Tantalum

Annealed:

- Ultimate Tensile Strength: 285 MPa (41 KSI)

- Yield Strength: 170 MPa (25 KSI)

- Elongation: >30%

- Hardness: 90 HV

- Other: 80%+ reduction in area

Cold Worked:

- Ultimate Tensile Strength: 650 MPa (95 KSI)

- Elongation: ~5%

- Hardness: 210 HV

Additional Properties

- Poisson’s Ratio: 0.35

- Elastic Modulus (Tension): 186 GPa (27 × 10⁶ PSI)

- Ductile-Brittle Transition Temperature: < 75 K

- Recrystallization Temperature: 900 – 1,200°C

Reviews

There are no reviews yet.