In the world of industrial electrochemical processes, the anode is a critical component, directly impacting efficiency, energy consumption, and operational lifespan. Among the most advanced and widely used anodes are Ruthenium-Iridium Titanium Electrodes, often recognized by their coating type as Mixed Metal Oxide (MMO) electrodes or as a form of Dimensionally Stable Anodes (DSAs). These electrodes, built on a titanium substrate and coated with a precious metal oxide layer primarily composed of ruthenium dioxide (RuO2) and iridium dioxide (IrO2), are essential for driving sustainable and cost-effective reactions across numerous industries.

Their exceptional performance stems from the synergistic properties of the coating materials and the titanium base, offering unparalleled corrosion resistance, catalytic activity, and durability in harsh electrochemical environments.

What Defines a Ruthenium-Iridium Titanium Electrode?

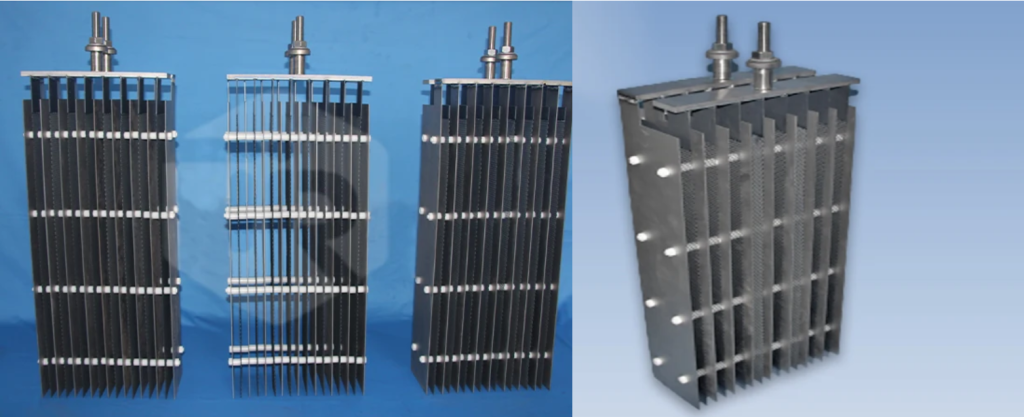

A Ruthenium-Iridium Titanium Electrode is not just a piece of metal; it’s a sophisticated composite structure designed for specific electrochemical reactions:

- Substrate: The foundation is typically Grade 1 Titanium. Titanium is chosen for its outstanding corrosion resistance, passivation properties in anodic environments (it forms a stable, non-conductive oxide layer), and good electrical conductivity. It provides mechanical strength and a stable base for the catalytic coating.

- Coating: This is the active part, a thin layer of Mixed Metal Oxides (MMO). The primary components are ruthenium dioxide (RuO2) and iridium dioxide (IrO2). The precise ratio of these oxides, and sometimes the inclusion of other metal oxides, is carefully controlled during manufacturing to optimize performance for specific applications.

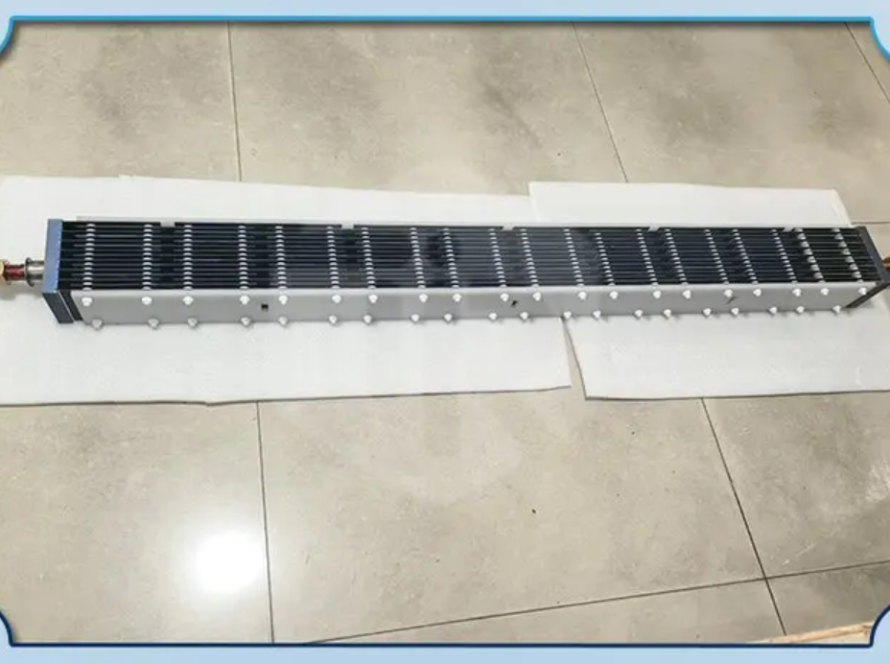

- Structure: The MMO coating is applied to the titanium substrate through proprietary thermal decomposition methods. The result is a robust, electrochemically active layer with a high surface area at a controlled thickness (commonly around 8 micrometers), offering excellent adhesion to the titanium.

The Synergistic Power: Why Ru-Ir?

The combination of ruthenium and iridium oxides is key to the electrode’s superior performance, particularly in reactions involving chlorine and oxygen evolution:

- Ruthenium (RuO2): Highly catalytic for the Chlorine Evolution Reaction (CER). It significantly lowers the overpotential required to produce chlorine gas from chloride solutions, making processes like chlor-alkali production energy-efficient.

- Iridium (IrO2): Offers excellent catalytic activity for the Oxygen Evolution Reaction (OER) and, crucially, provides exceptional corrosion resistance and stability, especially in conditions where side reactions like oxygen evolution occur or at higher anodic potentials. Iridium enhances the overall durability and service life of the electrode.

- The Blend: The mixed oxide coating leverages the high CER activity of Ru with the stability and OER activity of Ir, creating a versatile anode that performs efficiently and reliably in complex electrolytic solutions.

Key Advantages and Benefits

The design and composition of Ruthenium-Iridium Titanium Electrodes translate into significant operational advantages:

- Superior Corrosion Resistance: Highly resistant to aggressive chemicals, acids, and corrosive ions present in industrial electrolytes, ensuring integrity and performance over time.

- High Catalytic Efficiency: Lowers the reaction overpotential, leading to reduced energy consumption and higher current efficiency compared to traditional electrode materials like graphite or lead alloys.

- Energy Efficiency: Directly contributes to lower operating costs by decreasing the voltage required for electrolysis.

- Long Service Life: Engineered for durability, these electrodes can operate effectively for many years (often cited as 8+ years in continuous industrial operation), minimizing downtime and replacement costs.

- Dimensionally Stable: Unlike graphite, which degrades and changes shape, DSAs maintain their form throughout their service life, allowing for consistent cell design and performance.

- Lightweight & Strong: Inherits the excellent strength-to-weight ratio of the titanium substrate.

- Recyclable Substrate: The valuable titanium base can often be stripped of the old coating and recoated, offering a cost-effective and environmentally friendly option for electrode refurbishment.

- Versatility: Adaptable to a wide range of electrochemical processes by adjusting the coating composition.

Where Ruthenium-Iridium Titanium Electrodes Drive Innovation

The unique properties of Ru-Ir Ti electrodes make them indispensable in various critical industrial and environmental applications:

- Chlor-Alkali Industry: This is perhaps the most significant application. They are the standard anode material in modern membrane and diaphragm electrolytic cells for the production of chlorine gas (Cl2), caustic soda (NaOH), and hydrogen gas (H2) from brine (NaCl) solution. They replaced older, less efficient mercury and diaphragm processes.

- Water and Wastewater Treatment: Used for electrochemical disinfection (generating hypochlorite in situ), oxidation of organic pollutants (reducing COD/BOD), removal of ammonia and nitrates, and electrochemical recovery/removal of heavy metals.

- Swimming Pool Chlorinators: Provides a durable, efficient, and reliable method for generating chlorine directly from saltwater pools.

- Electrorefining and Electroplating: Enhances efficiency and purity in processes like copper foil production and precious metal plating.

- Electrosynthesis: Used in the production of various chemicals through electrochemical routes.

- Cathodic Protection: Can be used as impressed current anodes for corrosion prevention of structures.

- Food Safety: Employed in electrochemical systems for disinfecting water used in washing fruits and vegetables.

Sourcing High-Quality Ru-Ir Titanium Electrodes

Given their critical role, the performance and lifespan of Ruthenium-Iridium Titanium Electrodes depend heavily on the quality of the titanium substrate and, crucially, the expertise in applying the active MMO coating. Factors like surface preparation, coating composition precision, thickness uniformity, and adherence are paramount.

When seeking these specialized electrodes, it is essential to partner with manufacturers and suppliers who possess deep technical knowledge in both titanium metallurgy and advanced mixed metal oxide coating technologies. Leading suppliers offer not only standard products but also the capability for customized coating formulations and electrode designs tailored to the specific electrolyte composition, current density, desired product purity, and operational life requirements of your application. This ensures optimal performance and maximizes return on investment.

Ruthenium-Iridium Titanium Electrodes stand as a testament to advancements in materials science, offering a powerful combination of catalytic efficiency, corrosion resistance, and longevity. Their role as Dimensionally Stable Anodes has revolutionized energy-intensive processes like chlor-alkali production and continues to be vital in addressing modern challenges such as effective water treatment and sustainable chemical synthesis. Investing in high-quality Ru-Ir Ti electrodes is investing in efficiency, reliability, and environmental responsibility.

FAQs About Ruthenium-Iridium Titanium Electrodes

What industries benefit the most from using ruthenium-iridium titanium electrodes?

Industries that rely heavily on electrolysis benefit significantly, particularly the Chlor-Alkali industry (for chlorine, caustic soda, hydrogen production) and the Water and Wastewater Treatment sector (for disinfection, pollutant removal, heavy metal recovery). Other major beneficiaries include electroplating, electrorefining, and chemical electrosynthesis.

How do ruthenium-iridium titanium electrodes enhance the efficiency of chlor-alkali production?

They replace older technologies by acting as highly catalytic anodes. Their low overpotential for the chlorine evolution reaction significantly reduces the electrical energy required for electrolysis, leading to lower power consumption per unit of product. Their long service life also reduces downtime and maintenance costs compared to consumable anodes like graphite.

What makes ruthenium-iridium titanium electrodes ideal for wastewater treatment?

Their strong electrocatalytic oxidative power allows them to break down persistent organic pollutants and generate disinfectants like hypochlorite in situ from chlorides naturally present in water. Their durability and corrosion resistance enable them to perform effectively in diverse and sometimes aggressive wastewater streams, offering a reliable method for disinfection and pollutant removal.

What does MMO stand for in the context of these electrodes?

MMO stands for Mixed Metal Oxide. It refers to the electrocatalytic coating applied to the titanium substrate, which in the case of these electrodes, is primarily a mixture of ruthenium dioxide (RuO2) and iridium dioxide (IrO2).

Can the composition of the Ru-Ir coating be customized?

Yes, reputable manufacturers often offer customization of the MMO coating composition. The ratio of ruthenium to iridium, and the inclusion of other metal oxides, can be adjusted to optimize the electrode’s performance, selectivity, and lifespan for specific electrolytic solutions and operating conditions (like electrolyte type, concentration, temperature, and current density).