Ti Time: An Outstanding Manufacturer and Supplier of Metal Materials

Titanium sheet metal is widely valued for its exceptional strength-to-weight ratio, corrosion resistance, and long-term stability, making it indispensable across aerospace, chemical processing, medical devices, water treatment, and advanced electrochemical systems. Selecting a reliable manufacturer is critical, as the performance of titanium—density ~4.5 g/cm³, tensile…

Titanium sheet metal is a versatile material prized for its strength-to-weight ratio and corrosion resistance, making it ideal for aerospace, medical, and marine applications. If you're handling thin titanium sheet metal, remember that it cuts slower than aluminum or mild steel due to its toughness, so patience and the right techniques are key. With proper…

In industries where every gram of weight matters and failure is not an option, standard steel simply cannot compete. This is where the Titanium screw and advanced titanium fasteners come into play. As a premier Ti Time Company titanium fasteners supplier, we understand that whether you are engineering a Formula 1 race car or a…

In modern engineering, few materials demand as much respect—and expertise—as titanium. Engineers choose titanium not because it is easy to process, but because it delivers performance that other metals cannot match. High strength at low weight, exceptional corrosion resistance, and proven biocompatibility make titanium indispensable in aerospace, medical, marine, and advanced industrial applications.

Turning titanium’s…

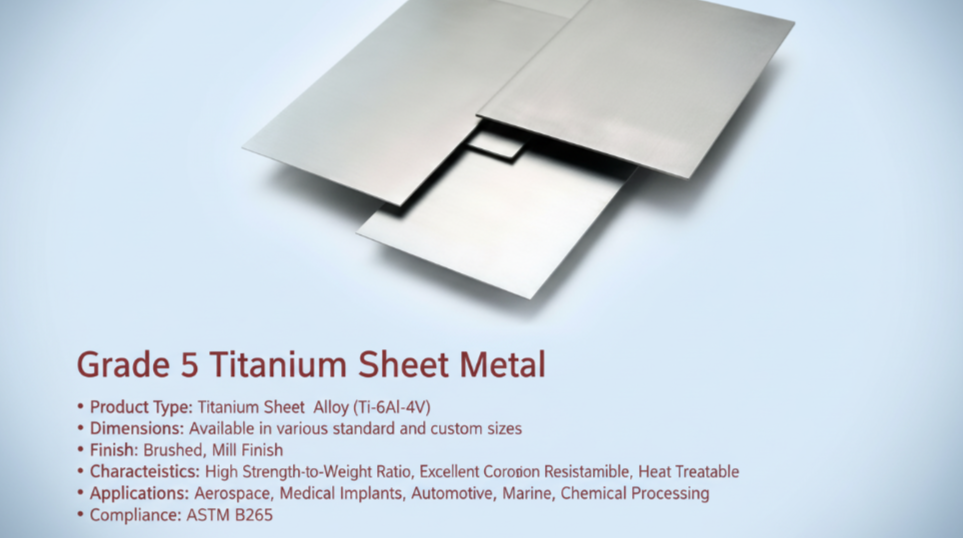

When selecting titanium sheet metal for your next project, the choice often boils down to two heavyweights: Grade 5 (Ti-6Al-4V) and Grade 2 (Commercially Pure). While both share the legendary lightweight and corrosion-resistant properties of titanium, they serve vastly different engineering needs.

As a leading Grade 5 titanium sheet metal supplier, Ti Time Company understands…

High-Purity Titanium Sputtering Targets for Precision Coating Applications

Ti Time Company is a leading manufacturer and supplier of titanium sputtering targets (Ti targets) designed for PVD and magnetron sputtering systems. With decades of experience in advanced materials engineering, Ti Time provides high-purity, high-density titanium targets used to produce durable, uniform coatings in electronics, optics, aerospace,…

Advanced Titanium-Molybdenum Alloys for Aerospace, Biomedical, and Industrial Innovation

Ti Time Company is a leading manufacturer and supplier specializing in titanium molybdenum alloys, offering advanced materials engineered for performance-critical environments. With decades of metallurgical experience and world-class production facilities, Ti Time delivers customized Ti-Mo alloys designed for aerospace, medical, and high-temperature structural applications.

Titanium-molybdenum alloys…

Titanium is one of the most valuable engineering materials today, prized for its lightweight strength, excellent corrosion resistance, and superior biocompatibility. As industries such as aerospace, medical, marine, chemical processing, and energy continue to expand, the demand for high-quality titanium products is steadily rising.

Choosing the right titanium distributor is crucial to ensure consistent supply,…

Titanium Tantalum Alloy (Ti-Ta ) is a highly specialized material that combines the lightweight, corrosion-resistant properties of titanium with the exceptional biocompatibility and chemical stability of tantalum. This alloy is widely used in medical implants, aerospace engineering, and advanced chemical processing equipment where strength, durability, and biocompatibility are essential.

As a trusted Titanium Tantalum Alloy…

Is Titanium Harder Than Steel?

A common question in materials science is whether titanium is harder than steel. The answer depends on the type of steel being compared:

Titanium alloys usually have a hardness of 300–400 HV (Vickers Hardness).

Standard stainless steels typically range from 150–300 HV.

Hardened steels (e.g.,…

Introduction to Ti-6Al-2Sn-4Zr-6Mo

Ti-6Al-2Sn-4Zr-6Mo (commonly known as Ti-6-2-4-6) is a high-strength alpha-beta titanium alloy engineered for use in elevated temperature environments. With excellent corrosion resistance, fatigue strength, and thermal stability up to 450°C (842°F), this alloy is widely used in aerospace, defense, oil & gas, and motorsport industries.

At Ti Time Company, we are a…

Introduction to Ti-13V-11Cr-3Al

Ti-13V-11Cr-3Al is a high-strength metastable beta titanium alloy, well-known for its outstanding strength-to-weight ratio, fatigue resistance, and corrosion resistance. With a composition of ~13% vanadium, 11% chromium, and 3% aluminum, this alloy is particularly suited for aerospace, defense, and high-performance structural applications.

At Ti Time Company, we specialize in the custom production…