Introduction to Ti-13V-11Cr-3Al

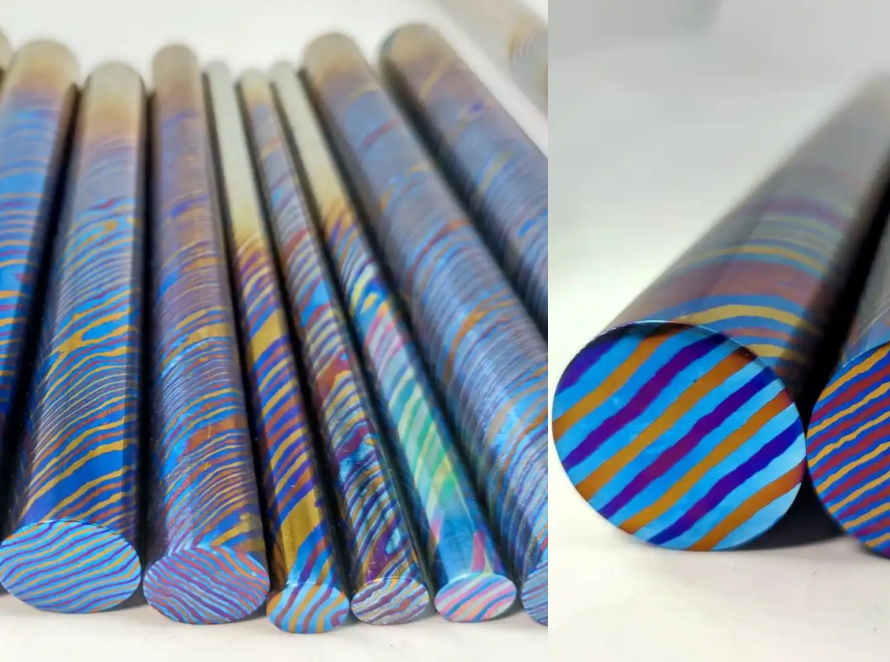

Ti-13V-11Cr-3Al is a high-strength metastable beta titanium alloy, well-known for its outstanding strength-to-weight ratio, fatigue resistance, and corrosion resistance. With a composition of ~13% vanadium, 11% chromium, and 3% aluminum, this alloy is particularly suited for aerospace, defense, and high-performance structural applications.

At Ti Time Company, we specialize in the custom production and supply of Ti-13V-11Cr-3Al alloy products, ensuring that every component meets the highest international standards for aerospace and industrial use.

Key Properties of Ti-13V-11Cr-3Al

Density: 4.82–4.84 g/cm³

Tensile Strength: 1200–1276 MPa

Yield Strength: ~1207 MPa

Hardness: ~40 HRC

Elastic Modulus: ~101 GPa

Thermal Expansion: ~9.5 x 10⁻⁶/°C

Corrosion Resistance: Excellent in seawater and stress corrosion environments

Heat Treatment: Solution treated and aged for maximum strength

Processing & Machinability

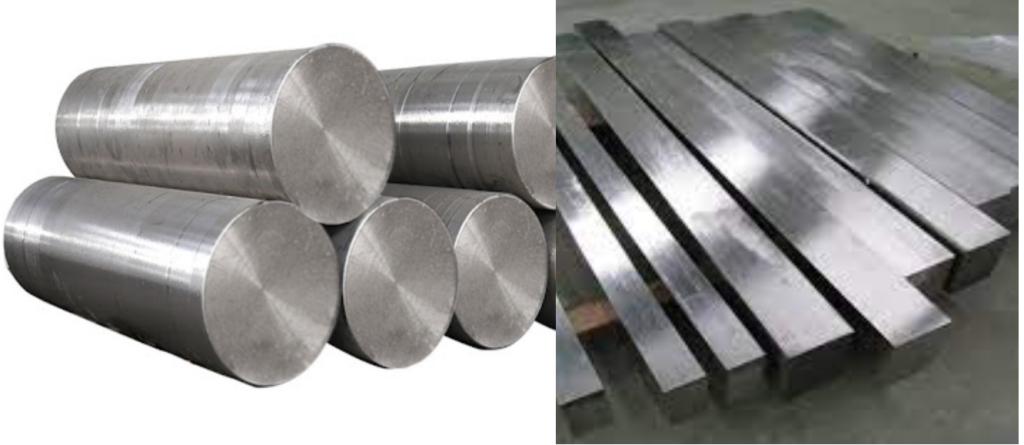

Supplied in bars, wires, sheets, tubes, plates, and forgings

Heat treatable for enhanced strength and toughness

Machining requires special tooling due to hardness and low thermal conductivity

Welding possible with inert gas shielding (argon or helium preferred)

Cold and hot forming feasible with proper processing control

Why Choose Ti Time Company as Your Supplier?

As a leading manufacturer and supplier of advanced titanium alloys, Ti Time Company offers:

Experience: Decades of expertise in aerospace-grade titanium alloys

Expertise: Technical know-how in beta titanium processing and welding solutions

Authoritativeness: Trusted by global aerospace and defense partners

Credibility: Certified quality assurance with full traceability

We provide customized manufacturing solutions for Ti-13V-11Cr-3Al and related titanium alloys, ensuring each client’s unique project requirements are fully met.

FAQs – Ti 13V 11Cr 3Al

1. What makes Ti-13V-11Cr-3Al different from other titanium alloys?

It is a metastable beta alloy with extremely high strength, deep hardenability, and superior fatigue resistance compared to alpha or alpha-beta titanium alloys.

2. Can Ti-13V-11Cr-3Al be welded to steel?

Direct fusion welding is not recommended due to brittle intermetallics. Instead, friction welding or bimetallic transition inserts are used for reliable joints.

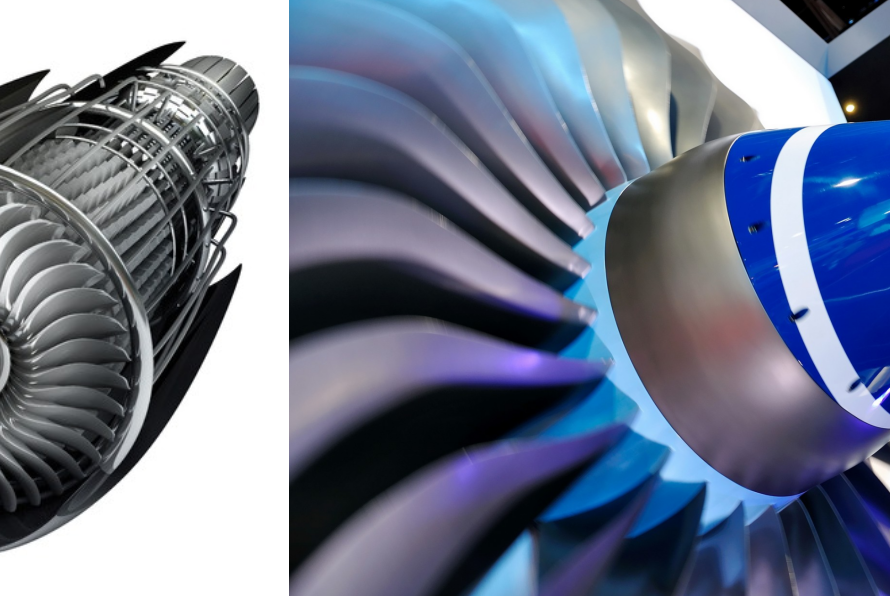

3. What industries mainly use Ti-13V-11Cr-3Al?

Primarily aerospace, defense, and high-performance engineering sectors requiring lightweight yet ultra-strong materials.

4. Is Ti-13V-11Cr-3Al corrosion resistant?

Yes, it offers excellent resistance to seawater, stress corrosion cracking, and harsh environments.

5. Does Ti Time Company offer custom Ti-13V-11Cr-3Al components?

Absolutely. We provide custom design, forging, machining, and electropolishing services to meet exact client needs.