Introduction to Ti-6Al-2Sn-4Zr-6Mo

Ti-6Al-2Sn-4Zr-6Mo (commonly known as Ti-6-2-4-6) is a high-strength alpha-beta titanium alloy engineered for use in elevated temperature environments. With excellent corrosion resistance, fatigue strength, and thermal stability up to 450°C (842°F), this alloy is widely used in aerospace, defense, oil & gas, and motorsport industries.

At Ti Time Company, we are a leading manufacturer and supplier of titanium alloys, including Ti-6-2-4-6, offering custom production, machining, forging, and surface finishing services to meet precise engineering demands.

Key Properties of Ti-6Al-2Sn-4Zr-6Mo

Density: ~4.64 g/cm³

Tensile Strength: ~1200–1276 MPa

Yield Strength: ~965 MPa

Elongation: ~6–13%

Elastic Modulus: ~107 GPa

Corrosion Resistance: Excellent in seawater and hydrogen sulfide environments

Thermal Stability: Retains high strength up to 450°C

Fatigue Resistance: Exceptional, especially under low-cycle fatigue conditions

Applications of Ti-6Al-2Sn-4Zr-6Mo

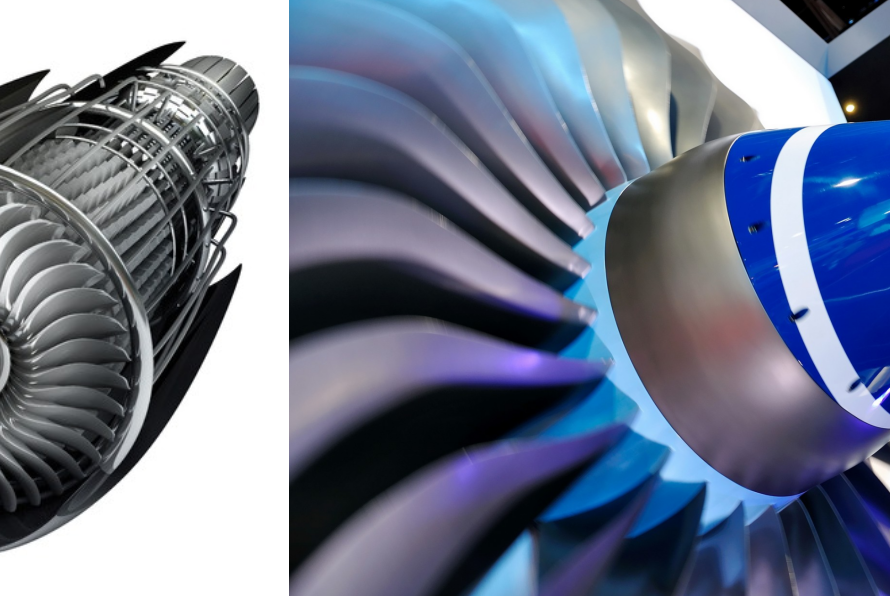

Aerospace: Intermediate compressor stages, discs, blades, seals

High-temperature airframe parts

Energy sector: Offshore & subsea oil and gas equipment

Motorsports: High-performance racing components with superior strength-to-weight ratio

Why Choose Ti Time Company as Your Supplier?

At Ti Time Company, we combine decades of experience with cutting-edge expertise in titanium alloy manufacturing. As a trusted titanium steel supplier, we ensure:

Experience: Proven track record in aerospace-grade titanium supply

Expertise: Deep knowledge of heat treatment, machining, and surface finishing

Authoritativeness: Recognized partner for global aerospace and energy industries

Credibility: Certified quality systems with full traceability

We provide customized production solutions for Ti-6-2-4-6 alloy, covering forging, machining, welding consultation, and electropolishing to deliver ready-to-use parts.

FAQs – Ti 6Al 2Sn 4Zr 6Mo

1. What is Ti-6Al-2Sn-4Zr-6Mo mainly used for?

It is primarily used in aerospace turbine engines (discs and blades), airframes, and offshore oil & gas components due to its thermal stability and fatigue resistance.

2. How strong is Ti-6-2-4-6 compared to Ti-6Al-4V?

Ti-6-2-4-6 has higher tensile and yield strength, with better high-temperature performance than Ti-6Al-4V.

3. Can Ti-6-2-4-6 be welded to steel?

Direct fusion welding is not recommended. Friction welding or transition inserts are preferred for joining titanium alloys with steel.

4. Is Ti-6-2-4-6 corrosion resistant?

Yes. It performs exceptionally well in seawater, hydrogen sulfide, and harsh environments, making it ideal for marine and subsea applications.

5. Does Ti Time Company offer custom parts in Ti-6-2-4-6?

Yes. We supply custom forged, machined, and finished parts tailored to aerospace, defense, and industrial requirements.