Introduction

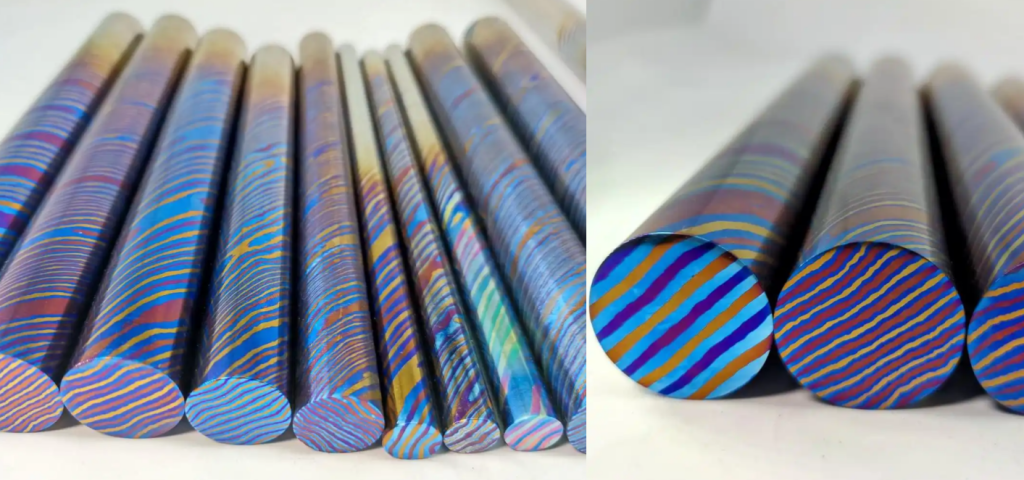

Ti 6Al 4V (Grade 5 Titanium Alloy) is one of the most widely used and versatile titanium alloys globally. Known for its excellent balance of strength, weight, and corrosion resistance, it is the go-to material in aerospace, automotive, medical, and chemical processing industries. As a trusted Ti 6Al 4V supplier, Ti Time Company provides high-quality, custom-manufactured titanium alloy products to meet the diverse needs of industries worldwide.

What is Ti 6Al 4V?

Composition: 90% titanium, 6% aluminum, 4% vanadium, with trace elements such as carbon, oxygen, nitrogen, hydrogen, and iron.

Key Properties of Ti 6Al 4V

Type: Alpha-beta titanium alloy (Al stabilizes alpha, V stabilizes beta)

Density: 4.43 – 4.51 g/cm³

Melting Point: 1604 – 1660 °C

Tensile Strength:

Ultimate tensile strength: 900 – 1170 MPa

Yield strength: 880 – 1100 MPa

Elongation at Break: 5 – 10%

Modulus of Elasticity: 104 – 114 GPa

Hardness: Rockwell C ~36

Thermal Conductivity: 6.7 – 7.5 W/m·K (low)

Corrosion Resistance: Excellent – resistant to seawater, nitric acid, alkalis

Heat Treatment: Mill annealed, solution treated, aged, stress relieved, or beta annealed

Weldability: Good – gas tungsten arc welding under inert gases recommended

Machinability: Good – requires sharp tools, low cutting speeds, cutting fluids

This combination of high strength, light weight, corrosion resistance, and workability makes Ti 6Al 4V the preferred alloy in critical industries.

Applications of Ti 6Al 4V

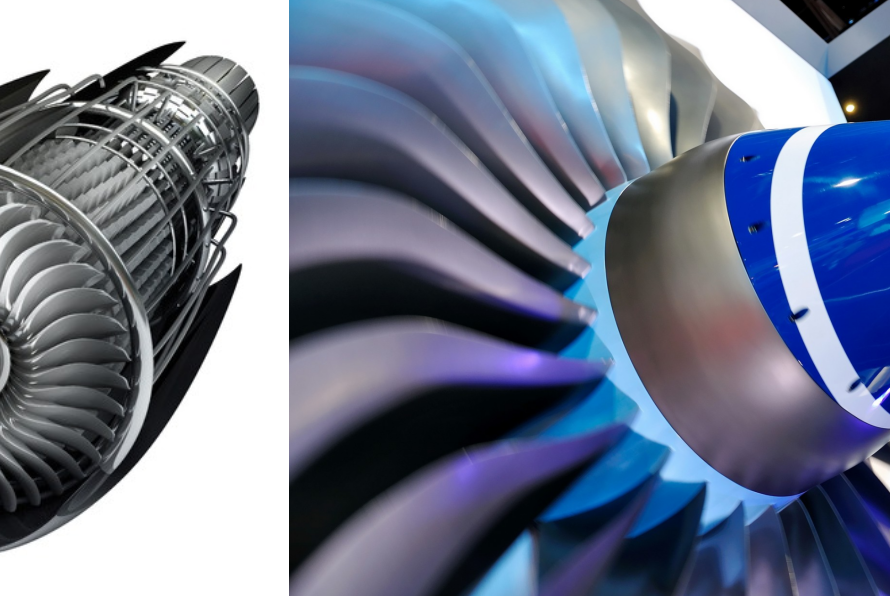

Aerospace: Aircraft engines, landing gear, structural components

Automotive: High-performance racing components, exhaust systems

Medical: Implants, surgical instruments, orthopedic devices

Energy & Chemical: Heat exchangers, offshore equipment, chemical processing units

Why Choose Ti Time Company as Your Ti 6Al 4V Supplier?

Ti Time Company is a leading global titanium alloy manufacturer and supplier with extensive experience in custom production and precision engineering. We provide:

Expertise (E): Decades of experience in titanium R&D and industrial applications

Authoritativeness (A): Certified quality systems ensuring global compliance

Trustworthiness (T): Strict QC, advanced facilities, and customer-focused solutions

Customization: Tailored Ti 6Al 4V and Titanium gold alloy products to meet unique project requirements

Whether you need raw titanium bars, sheets, medical-grade implants, or aerospace-grade components, Ti Time Company is your reliable partner.

FAQs about Ti 6Al 4V Supplier

What industries use Ti 6Al 4V the most?

Ti 6Al 4V is widely used in aerospace, medical implants, automotive racing, and chemical processing due to its superior strength-to-weight ratio and corrosion resistance.

Can Ti Time Company provide customized Ti 6Al 4V products?

Yes, Ti Time Company specializes in custom manufacturing and can deliver Ti 6Al 4V in different forms such as bars, plates, sheets, forgings, and precision components.

How does Ti 6Al 4V compare to pure titanium?

Pure titanium has excellent corrosion resistance but lower strength. Ti 6Al 4V offers a balance of strength, toughness, and corrosion resistance, making it more versatile.

Is Ti 6Al 4V biocompatible for medical use?

Yes, Ti 6Al 4V is biocompatible and commonly used for medical implants such as hip replacements and dental implants.

How does Ti Time Company ensure product quality?

Our products undergo strict quality control, including mechanical testing, chemical analysis, ultrasonic inspection, and compliance with ASTM and ISO standards.

Conclusion

Ti 6Al 4V is a high-performance titanium alloy trusted by industries worldwide. With unmatched experience, expertise, and reliability, Ti Time Company stands out as a leading global Ti 6Al 4V supplier. Whether your project requires aerospace-grade precision or medical-grade safety, Ti Time delivers titanium solutions you can trust.