1. What Makes Timascus Knives Unique?

Experience: A Fusion of Craft and Innovation

Born from the minds of skilled craftsmen and refined through years of trial and error, Timascus was invented by renowned American bladesmith Tom Ferry. The result is a material that not only offers functional performance but also elevates knives into objects of artistic expression.

Expertise: The Science Behind the Beauty

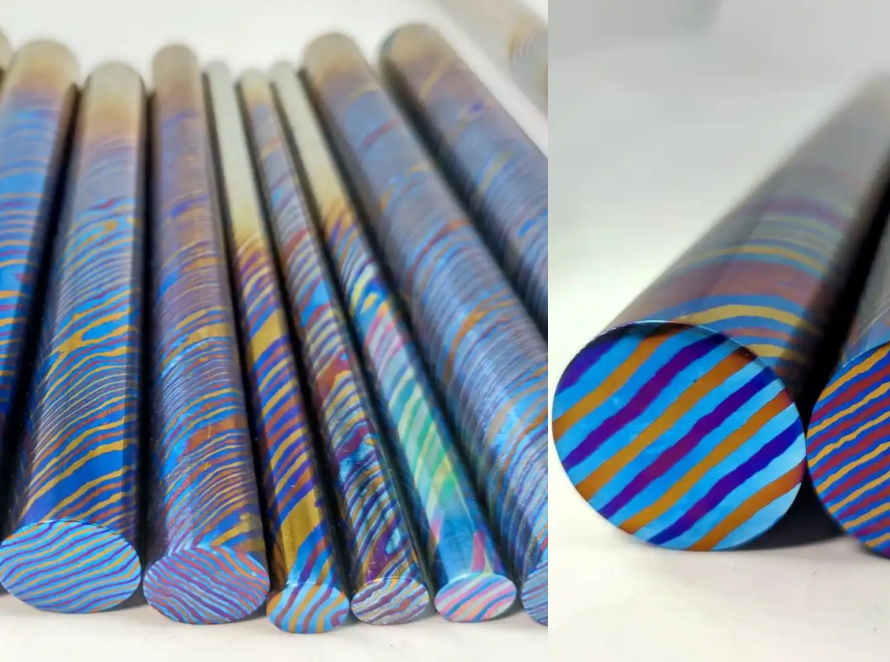

Timascus is produced by diffusion bonding and forge-welding multiple titanium alloys—most commonly Commercially Pure Titanium (CP) and Ti-6Al-4V—into a multilayer billet. The end result features between 50 and 300 layers of titanium alloy, which when heat-treated or anodized, reveal rich and contrasting colors from blues and purples to golds and greens.

2. Key Features of Timascus Custom Knives

✦ Lightweight & Strong

Titanium is 40% lighter than steel, yet boasts exceptional strength and durability. Timascus knives are ideal for everyday carry (EDC) and outdoor use.

✦ Striking Aesthetics

Through heat treatment or anodization, the layered titanium reveals vibrant, swirling patterns that are never repeated—each knife is truly one-of-a-kind.

✦ Corrosion & Magnetism Resistance

Perfect for humid or marine environments, and safe for electronic-sensitive operations due to its non-magnetic properties.

✦ High-End Craftsmanship

The production process is complex, involving multiple rounds of forging, welding, grinding, and coloring, with over 80% material loss. This contributes to the high cost and exclusivity of Timascus knives.

3. The Timascus Knife-Making Process

Material Preparation: Cleaned titanium alloy sheets are layered and sealed in an inert atmosphere.

Diffusion Welding: Bonded at ~1200°C under pressure to fuse the layers without oxidation.

Forging & Rolling: The billet is shaped and flattened to form a knife-scale-ready blank.

Machining & Shaping: Blanks are milled, ground, and polished to expose the layers and define the final form.

Coloring via Heat or Anodization: Controlled oxidation creates the brilliant, multicolored finish unique to Timascus.

4. Applications of Timascus in Knife Design

Knife Handles / Scales: The most popular use due to aesthetics, lightweight, and comfort.

Inlays & Pocket Clips: Adds visual contrast and sophistication to folder knives.

Bolsters and Decorative Elements: Enhances the artistic value of custom and collector-grade knives.

Crossovers: Used in luxury watch parts, jewelry, and EDC accessories.

5. Trusted Makers and Suppliers

Tom Ferry: Creator of Timascus and master bladesmith.

Noblie Custom Knives: High-end custom knife brand featuring Timascus in their premium offerings.

Alpha Knife Supply (AKS): Leading supplier of Timascus billets, scales, and tools for custom makers worldwide.

FAQs – Timascus Custom Knives

What are the key steps in Timascus knife-making?

It includes diffusion bonding, forging, precision machining, and heat/anodic coloring to create multilayered, artistic handle components.

What innovations does Timascus bring to knife design?

Beyond beauty, it introduces lightweight, corrosion-proof, and non-magnetic materials to traditionally steel-dominated crafts.

Why is Timascus preferred over Damascus steel in high-end custom knives?

While Damascus steel offers aesthetic layering, Timascus adds vibrant coloration, corrosion resistance, and weight savings.

How do different titanium alloys affect the final look?

Combining CP titanium with Ti-6Al-4V or beta titanium alloys affects the way colors form during oxidation, allowing for tailored patterns and contrast.

How can anodizing personalize a Timascus knife?

Makers control voltage or heat to adjust oxide thickness, letting users choose color schemes ranging from deep blues to iridescent golds and purples.